2025R

Compact Tractor

- Standard LED headlights and fender lights

- Hydro transmission with TwinTouch™ pedals for ease of use

- AutoConnect™ mid-mower deck can be installed or removed in less than 5 minutes

Starting At:

$20,923.00

View Product Brochure

Features

3-cylinder Yanmar TNV Series diesel engine

3-cylinder Yanmar TNV Series diesel engine

Power is provided by a durable and efficient high-torque three-cylinder Yanmar® TNV Series diesel engine.

This series of engines was developed to meet Tier 4 Environmental Protection Agency (EPA) environmental requirements by featuring low levels of both exhaust and emissions.

Model |

Number of |

Engine |

Gross engine power |

Power take-off (PTO) power |

2025R |

3 |

1.267 L |

18 kW (24.2 hp) |

12.8 kW (17.2 hp) |

Yanmar TNV Series engine offers these features:

- Economical for good cooling and long life

- Isolated engine provides reduced vibration and noise for the operator; indirect fuel injection uses a precombustion chamber to give the engine a smooth and quiet operation; aluminum-alloy piston with built-in steel struts are lightweight to reduce connection rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, thereby reducing blow-by gas and less noise from the piston slap

- Higher top rings on the piston and a thinner head gasket greatly reduces the volume of unburned waste gases and increases combustion efficiency

- Timing-gear teeth have a designed roll-off profile giving almost no clash, no noise, and no backlash

- High-torque reserve provides plenty of power under heavy load, yet retains excellent fuel economy

- Easy access to engine check and fill points on the right-hand side of the tractor by removing the side panels

- Fuel filter with replaceable element

- Full-pressure lubrication system provides filtered oil under pressure to all vital engine parts

- Glow plugs provide quick starts in temperatures down to -18°C (0°F) (Optional engine coolant heater attachment will assist starting under more extreme conditions.)

- Auto-bleed fuel system means there is no special bleeding required if the tractor runs out of fuel; this system will self-prime the injection pump, lines, and injectors, providing fast fuel recovery

- Key start and shut off eliminates fuel shut-off knob

- Electric solenoid shuts fuel supply off immediately when key is turned off

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Dry-type air cleaner with safety element keeps dirt and other contaminants out of the engine

- Safety element (second filter) will protect engine if primary filter would develop a leak

- Protects engine when servicing primary filter

- Air filter restriction indicator is standard equipment on the 2025R Tractor

- Sealed-radiator compartment keeps trash and debris on outside of hood

- Horizontal exhaust discharges fumes away from the operator station, reducing noise and improving operator visibility and comfort

Yanmar is a trademark of Yanmar Company Limited.

The 2R Series are equipped with a two-range hydrostatic transmission (HST) incorporated in a die-cast aluminum transmission case. Fluid under pressure transmits engine power to the drive wheels via a closed-loop pump and motor arrangement. Infinite ground speeds allow the operator to match the speed of the tractor to the job.

- No clutching for fast and easy direction changes

- Twin Touch™ foot pedals for quick and easy forward/reverse operation

- Transmission oil cooler cools transmission oil for longer transmission life

Safety features of the HST include:

- The tractor will only start with the range lever in neutral

- If the range lever is in gear when the key is turned to the start position, the instrument panel instructs the operator to shift to neutral

- The engine will shut off if the operator leaves the seat and the forward/reverse pedals are depressed

Twin Touch foot controls

Twin Touch foot controls

Two-range transmission

Two-speed transmission

Two-speed transmission

Transmission has two speeds - hi and lo range.

- The range lever is located next to the seat, conveniently within reach of the operator

- All tasks can be performed using two ranges on the 2025R which means less shifting throughout the day

Durability features include:

- Large forged one-piece trunnion shaft with larger support bearings that reduce vibration and noise

- Innovative transaxle combines an HST, gear reduction axle, and clutch

- Pressure side filtration allows the use of a fine-mesh filter

- One pump to supply charge pressure and implement A flow divider splits the flow to various circuits throughout the tractor.

- The transaxle has an oil cooler which provides improved hydraulic cooling performance

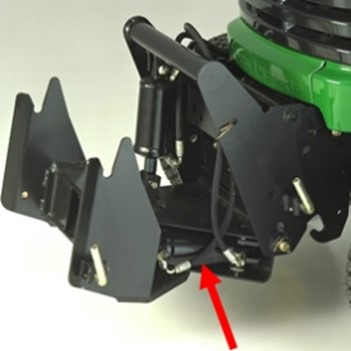

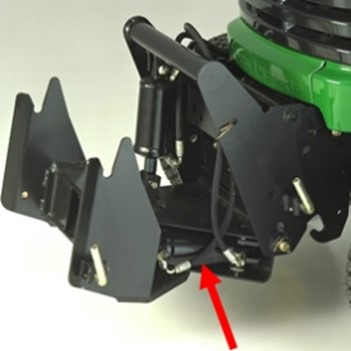

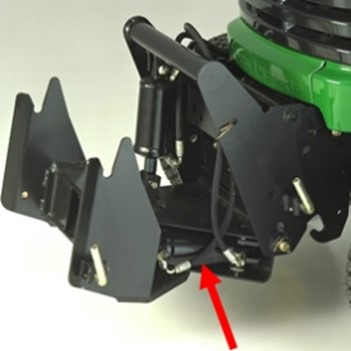

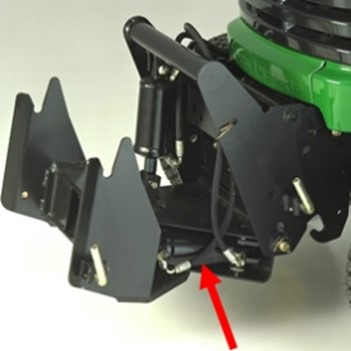

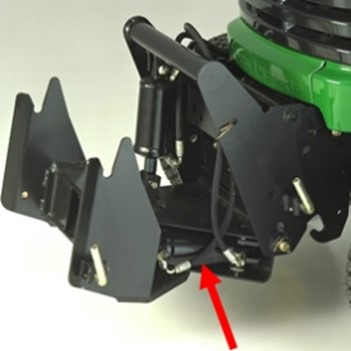

Easy to change implements

Easy to change implements

- Front Quik-Tatch™ hitch makes changing front implements quick and easy

- All front implements (blades, brooms, and snow blowers) use a common hitch

- AutoConnect™ Mid-Mount Mower Deck, 120R Loader, and 260B Backhoe can be taken on or off within 5 minutes, and no tools are required

- Changing rear implements is a snap with the iMatch™ Quick-Hitch, which has three fixed points to back in and pick up a rear implement that is iMatch compatible

Implement compounding (2025R Tractor shown)

Implement compounding (2025R Tractor shown)

- Loader, mid-mower, and a variety of rear hitch implements can be attached to the tractor at the same time

Optional premium independent mid lift system operates independent of the rear 3-point hitch. This gives the operator the flexibility to leave the mid mower attached when completing other tasks.

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

- Two quarter-turn fasteners allow operators to easily remove the engine side panels without tools to access to the engine compartment.

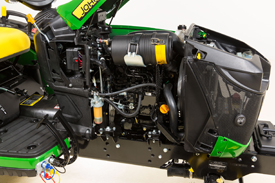

Fasteners on the engine side panels

Fasteners on the engine side panels

- The under-hood gas-lift support provides easy access to the engine compartment and eliminates the need for a mechanical prop rod.

Under-hood gas lift makes it easy to access the engine

Under-hood gas lift makes it easy to access the engine

External hood latch requires no tools and can release using the tractor key.

Easy access to regular service points minimizes service time.

Daily service checks, such as checking the engine oil or water separator, can be done without opening the hood or removing the tractor side panels.

Tractors are equipped with a mechanical air filter restriction indicator that alerts the operator when the air filter needs to be cleaned or changed.

Air filter restriction indicator

Air filter restriction indicator

- All external engine, fuel, and transmission filters are easily accessible.

- Fuel tank is located on the rear of the tractor to allow for easy access when fueling.

Fuel tank at rear of tractor

Fuel tank at rear of tractor

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

The Mauser cab offers protection from the elements and expands the versatility of 2025R Tractors to perform in all climates.

2025R cab

2025R cab

Key features:

- Full glass doors for maximum visibility

- Curved glass for a styled look

- Sealed for cold weather operation

- Easily removable for summer operation

- Heater with fan

- Switches and vents integrated into headliner

- Dome light

- Fully openable front and rear windows with gas struts

- Front sun visor

Operator view from inside the cab

Operator view from inside the cab

- Front work lights

Front work lights

Front work lights

- Front wiper with washer system

- Dual outside mirrors

- Rollover protective structure (ROPS) certified cab frame

- Allows for improved rear visibility

- Reduces overall height

- Rubber isolation at all mounting points

- Interior sound insulation

Interior sound insulation

Interior sound insulation

- Immersion-primed and powder-coated cab frame

- Provides superior corrosion resistance

- Integrated John Deere styling

John Deere styling on 2025R cab

John Deere styling on 2025R cab

Specifications:

- Cab height: 1495 mm (58.9 in.)

- Overall height when installed: 2040 mm (80.3 in.)

- Overall height when installed to top of beacon: 2210 mm (87 in.)

- Overall width with cab installed: same as tractor width

- Cab weight: 236 kg (520 lb)

Optional kits:

- Rotating beacon light – BXX10310

- Rear LED work light kit – BLV11083

- Mauser cab relocation bracket – BXX10507 (used with 1025R and 2025R Tractors with Mauser cab and mechanical-self-leveling [MSL] loaders)

- Prevents interference with Mauser cab and MSL loader mast

Compatibility and installation:

- Compatible with:

- Model year 2017 and newer 2025R Tractors

- Not compatible with:

- 260B Backhoe

Specs & Compare

Key Specs | 2025R Current Model |

| Engine power (gross) | SAE J1995 rated power: 17.8 kW 23.9 hp 24.2 PS at 3200 rpm |

| Power take-off (PTO) power | 12.8 kW 17.2 hp |

| Steering hydraulics | 13.4 L/min 3.5 gpm |

| Implement hydraulics | 13.4 L/min 3.5 gpm |

| Hitch type | Limited Category 1 |

| Lift capacity, 24-in. behind link arms | 415 kg 915 lb |

| Standard transmission; forward/reverse | Hydrostatic - two range |

| Cruise control | Standard |

| Approximate shipping weight (open-station; cab) | Open station: 849 kg 1872 lb Cab: 1085 kg 2392 lb |

| Wheelbase | 1600 mm 63 in. |

Engine | |

| Family | |

| Manufacturer | Yanmar® |

| Engine model | 3TNV80F-NCJT |

| Engine power (gross) | SAE J1995 rated power: 17.8 kW 23.9 hp 24.2 PS at 3200 rpm |

| Power take-off (PTO) power | 12.8 kW 17.2 hp |

| Rated engine speed | 3200 rpm |

| Type | Diesel |

| Injection pump type | Indirect injection |

| Aspiration | Natural |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | Three cylinders: 1.267 L 77 cu in. |

| Number of cylinders | Three |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 80 x 84 mm 3.2 x 3.3 in. |

| Compression ratio | 23.1:01 |

| Lubrication | Pressurized |

| Cooling system | Water pump |

| Air cleaner | Dual element |

| Engine torque at rated speed | 53.1 Nm 39.1 lb-ft |

| Fuel tank capacity | 20.4 L 5.39 gal. |

Electrical | |

| Battery size | 500 CCA |

| Alternator (12-V) | 40 amp |

| Starter size | 1.2 kW 1.6 hp |

Fuel system | |

| Type | Indirect injection |

| Fuel consumption | |

Transmission | |

| Standard transmission; forward/reverse | Hydrostatic - two range |

| Optional transmission; forward/reverse | |

| Left-hand reverser | No |

| Transmission gear ranges | |

| Final drive | Spur gear |

| Brakes | Wet disc |

| Steering | Power steering |

| Clutch, wet/dry | |

| Clutch disk diameter wet clutch | |

| Axle capacity | Front 612 kg 1349 lb Rear 1100 kg 2425 lb |

| Creeper | No |

| Cruise control | Standard |

| Differential lock | Yes |

| Drawbar maximum vertical load | |

Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 13.25 L/min 3.5 gpm Implement 13.25 L/min 3.5 gpm 26.5 L/min 7 gpm |

| Pump type | Gear |

| Maximum operating pressure | 137 bar 1987 psi |

| Draft control sensing | Position control |

| Remote control valves available | Two |

3-point hitch | |

| Type | Limited Category 1 |

| Lift capacity, 24-in. behind link arms | 415 kg 915 lb |

Power take-off (PTO) | |

| Standard | Rear - 540 rpm Mid - 2100 rpm |

| Optional | |

| Control | Independent |

| Clutch | Wet disk |

| Brake (for mid and rear PTO) | Wet disk |

| Engagement method | |

Fluid capacities | |

| Crankcase with filter | 2.7 L 2.9 qt |

| Transmission and hydraulic system | |

Final drive | |

| Type | Spur gear |

| Differential lock | Yes |

Operator station | |

| Rollover protective structure | Type Foldable OSHA, SAE, ASAE |

| Platform - flat/straddle | Three-piece semi flat |

| Gear shift location - console/floor | Left-hand side |

Cab | |

| Compliance | |

| Visibility | |

| Air conditioning, temperature differential | |

| Doors | |

| Noise rating | |

| Seat equipment | |

Dimensions | |

| Height | |

| Wheelbase | 1600 mm 63 in. |

| Front axle clearance | |

| Turning radius with brakes | |

| Turning radius without brakes | Outside front tire: 2.51 m 8.2 ft |

| Limited slip differential | No |

| Approximate shipping weight (open-station; cab) | Open station: 849 kg 1872 lb Cab: 1085 kg 2392 lb |

Tires | |

| Front | R3 Turf: 23x8.50-12 R3 Radial: 220/55-R12 R4 Industrial: 23x8.50-12 |

| Rear | R3 Turf: 12-16.5 R3 Radial: 280/70 R16 R4 Industrial: 12-16.5 |

| Front tread range | |

| Rear tread spacing | |

Miscellaneous | |

| Toolbox | Yes |

| Tilt steering wheel | Yes |

| 12-V Outlet | Yes |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

Backhoes

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

Front Hitch

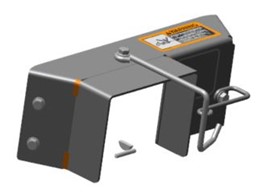

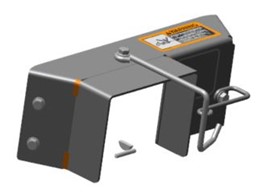

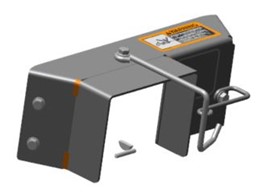

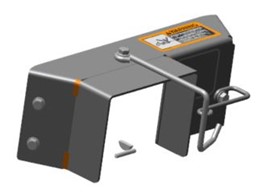

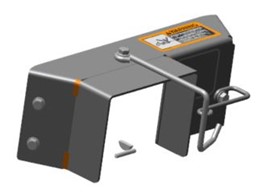

BLV10708 Quick Hitch shown

BLV10708 Quick Hitch shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10793 Snow Blower Mounting Kit shown

BLV10793 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BLV10899 Snow Blower Drive Shaft shown

BLV10899 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BLV10794 52” Broom Attaching Kit shown

BLV10794 52” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10900 Broom Drive Shaft shown

BLV10900 Broom Drive Shaft shown

Front Quick Hydraulic Angling Kit example shown

Front Quick Hydraulic Angling Kit example shown

Overview

Front quick hitch kits allow an operator to quickly install snow blowers, brooms and blades to the front of the tractor.

NOTE: Depending on the tractor and implement type, additional kits may be required to complete the install

Benefits

- Quick installation of implements

- Increased productivity

- Adaptable for various front mounted implements

BLV10708 Quick Hitch shown

BLV10708 Quick Hitch shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10793 Snow Blower Mounting Kit shown

BLV10793 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BLV10899 Snow Blower Drive Shaft shown

BLV10899 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BLV10794 52” Broom Attaching Kit shown

BLV10794 52” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10900 Broom Drive Shaft shown

BLV10900 Broom Drive Shaft shown

Front Quick Hydraulic Angling Kit example shown

Front Quick Hydraulic Angling Kit example shown

Overview

Front quick hitch kits allow an operator to quickly install snow blowers, brooms and blades to the front of the tractor.

NOTE: Depending on the tractor and implement type, additional kits may be required to complete the install

Benefits

- Quick installation of implements

- Increased productivity

- Adaptable for various front mounted implements

BLV10708 Quick Hitch shown

BLV10708 Quick Hitch shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10793 Snow Blower Mounting Kit shown

BLV10793 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BLV10899 Snow Blower Drive Shaft shown

BLV10899 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BLV10794 52” Broom Attaching Kit shown

BLV10794 52” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10900 Broom Drive Shaft shown

BLV10900 Broom Drive Shaft shown

Front Quick Hydraulic Angling Kit example shown

Front Quick Hydraulic Angling Kit example shown

Overview

Front quick hitch kits allow an operator to quickly install snow blowers, brooms and blades to the front of the tractor.

NOTE: Depending on the tractor and implement type, additional kits may be required to complete the install

Benefits

- Quick installation of implements

- Increased productivity

- Adaptable for various front mounted implements

BLV10708 Quick Hitch shown

BLV10708 Quick Hitch shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10793 Snow Blower Mounting Kit shown

BLV10793 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BLV10899 Snow Blower Drive Shaft shown

BLV10899 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BLV10794 52” Broom Attaching Kit shown

BLV10794 52” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10900 Broom Drive Shaft shown

BLV10900 Broom Drive Shaft shown

Front Quick Hydraulic Angling Kit example shown

Front Quick Hydraulic Angling Kit example shown

Overview

Front quick hitch kits allow an operator to quickly install snow blowers, brooms and blades to the front of the tractor.

NOTE: Depending on the tractor and implement type, additional kits may be required to complete the install

Benefits

- Quick installation of implements

- Increased productivity

- Adaptable for various front mounted implements

BLV10708 Quick Hitch shown

BLV10708 Quick Hitch shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10793 Snow Blower Mounting Kit shown

BLV10793 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BLV10899 Snow Blower Drive Shaft shown

BLV10899 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BLV10794 52” Broom Attaching Kit shown

BLV10794 52” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10900 Broom Drive Shaft shown

BLV10900 Broom Drive Shaft shown

Front Quick Hydraulic Angling Kit example shown

Front Quick Hydraulic Angling Kit example shown

Overview

Front quick hitch kits allow an operator to quickly install snow blowers, brooms and blades to the front of the tractor.

NOTE: Depending on the tractor and implement type, additional kits may be required to complete the install

Benefits

- Quick installation of implements

- Increased productivity

- Adaptable for various front mounted implements

Hydraulics

Frontier™ grapple shown on 120R and 2025R

Frontier™ grapple shown on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

120R loader connection location on 1E and 1R tractor

120R loader connection location on 1E and 1R tractor

120R loader connection on 2025R tractor

120R loader connection on 2025R tractor

Joystick for usage with third-function

Joystick for usage with third-function

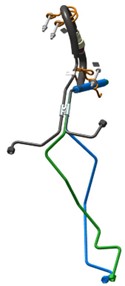

120R loader third-function lines on boom

120R loader third-function lines on boom

120R loader third-function connection for implements at torque tube area

120R loader third-function connection for implements at torque tube area

Overview

Add versatility to the tractor and loader package with the addition of a third-function kit. They enable the use of attachments such as four-in-one buckets, root grapples, and hydraulic angling blades further enhancing the tractors’ ability to help get jobs done.

Tractor series |

Loader model |

Loader bundle for non-self-leveling loaders |

Loader bundle for mechanical self- leveling loaders |

Tractor bundle |

MY20 and newer 1E and 1R |

120R |

BXX10268 |

BXX10370 |

BXX10835 |

MY20 and newer 2025R |

120R |

BXX10210 |

BXX10375 |

BXX10846 |

Frontier™ grapple shown on 120R and 2025R

Frontier™ grapple shown on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

120R loader connection location on 1E and 1R tractor

120R loader connection location on 1E and 1R tractor

120R loader connection on 2025R tractor

120R loader connection on 2025R tractor

Joystick for usage with third-function

Joystick for usage with third-function

120R loader third-function lines on boom

120R loader third-function lines on boom

120R loader third-function connection for implements at torque tube area

120R loader third-function connection for implements at torque tube area

Overview

Add versatility to the tractor and loader package with the addition of a third-function kit. They enable the use of attachments such as four-in-one buckets, root grapples, and hydraulic angling blades further enhancing the tractors’ ability to help get jobs done.

Tractor series |

Loader model |

Loader bundle for non-self-leveling loaders |

Loader bundle for mechanical self- leveling loaders |

Tractor bundle |

MY20 and newer 1E and 1R |

120R |

BXX10268 |

BXX10370 |

BXX10835 |

MY20 and newer 2025R |

120R |

BXX10210 |

BXX10375 |

BXX10846 |

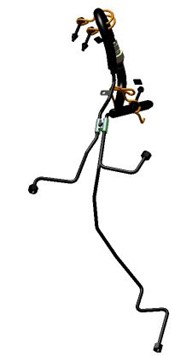

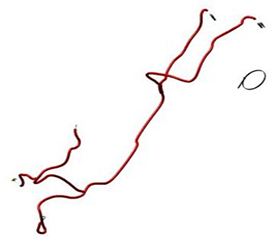

Power beyond kit example shown

Power beyond kit example shown

LVB25956 Power beyond kit shown

LVB25956 Power beyond kit shown

BLV11216 Power beyond kit shown

BLV11216 Power beyond kit shown

BXX10915 Power beyond kit shown

BXX10915 Power beyond kit shown

BXX10837 Power Beyond Kit shown

BXX10837 Power Beyond Kit shown

BLV10381 Power Beyond Kit shown

BLV10381 Power Beyond Kit shown

Overview

Power beyond kits provide access of pressurized hydraulic oil at the rear of the tractor for operating attachments equipped with an open center control valve, such as a backhoe and log splitter when continuous hydraulic flow is required.

NOTE: When nothing is hooked up to the power beyond, it is critical the loop is closed to ensure proper hydraulic flow.

NOTE: Power beyond kits are not included in the backhoe frame attachments and must be ordered separately.

Lighting

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

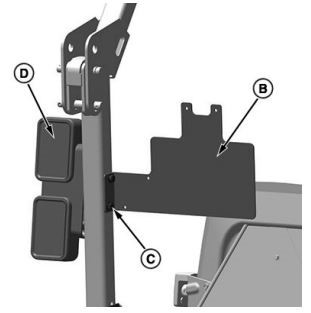

BLV10674 radio installation kit shown in 2025R cab

BLV10674 radio installation kit shown in 2025R cab

Overview

Dealer-installed attachments are available for the factory-installed cab on the 2025R Tractor to improve functionality and communicate to others in the surrounding area.

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

Open Operator's Station

LP64809 canopy shown

LP64809 canopy shown

Overview

Steel frame construction, ABS plastic roof. Approved for use on small chassis compact utility tractors with both fixed and folding roll over protective structures (ROPS). The canopy protects the operator from direct sun exposure and weather. Heavy-duty construction that is built to last.

BXX10277 License plate kit shown

BXX10277 License plate kit shown

Overview

License plate kits allow an operator to display a license plate on the tractor in order to meet local laws and regulations in which to drive on public roads.

LP95637 Tractor cover shown

LP95637 Tractor cover shown

Overview

Provide all-weather protection to the tractor when not in use with a tractor cover.

Benefits

- Weather resistant material

- Protects against UV damage, rain, dirt, etc.

- Keeps the seat dry

Operator's Station

Radio

BLV10674 radio installation kit shown in 2025R cab

BLV10674 radio installation kit shown in 2025R cab

Overview

Dealer-installed attachments are available for the factory-installed cab on the 2025R Tractor to improve functionality and communicate to others in the surrounding area.

Rear Power Take-Off (PTO)

Rear Wheel Weights

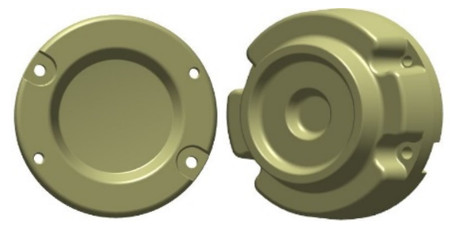

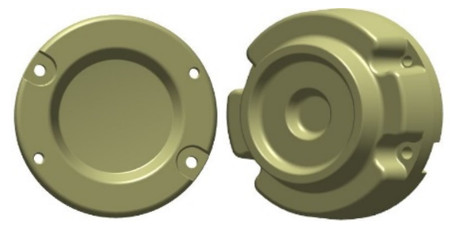

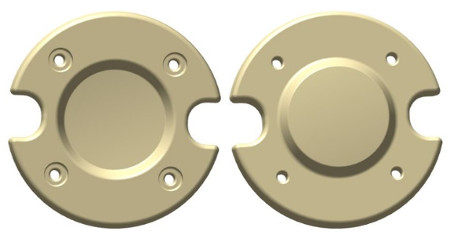

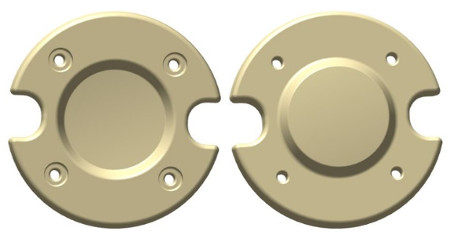

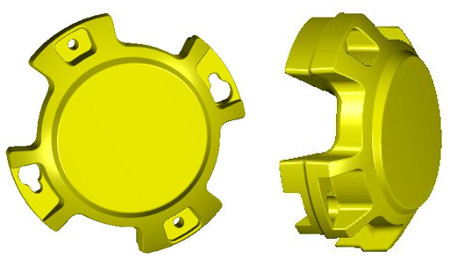

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

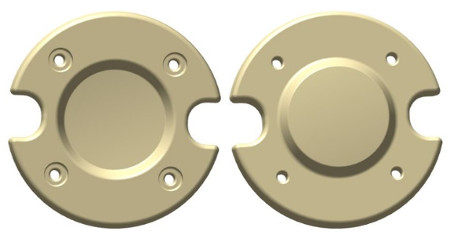

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

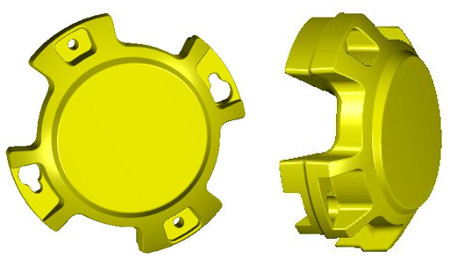

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

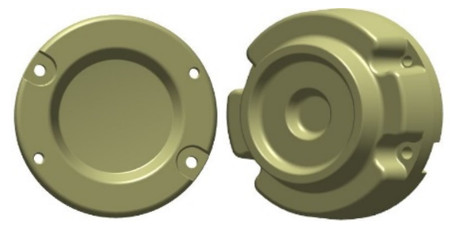

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

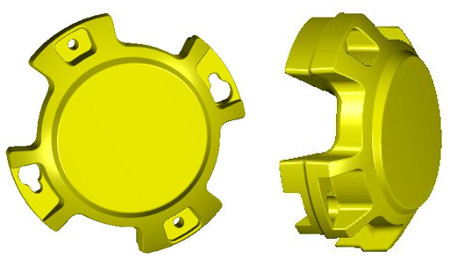

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

Rear Wheels and Tires

Three-Point Hitch

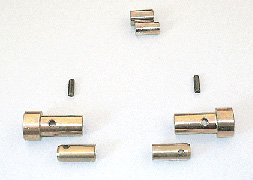

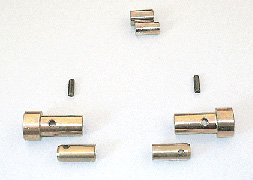

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

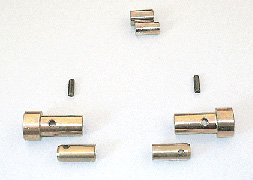

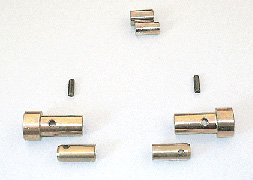

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

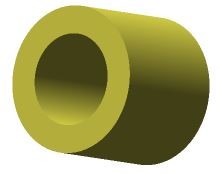

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

Reviews

Location: Warren Texas

Length of Ownership: 1yearOrLonger

Usage: Weekly

I purchased my 2025r in Beaumont Texas and is cheaply built

Location: Indiana

Length of Ownership: 1month

Usage: Daily

I recently traded my 2010 JD 2320 with a 62" drive over mower deck for a 2021 JD 2025R with a 60" auto-connect mower deck. I ordered this tractor and when it arrived this was sure a disappointment. The 2025R just seems cheap!! For example the individual brakes have been reduced to a single brake pedal, the drawbar has been replaced by a plate with a hole in it, the light that indicates that the 4WD is engaged no longer exists, the levers to shift the pto and hi and lo for the transmission seem very flimsy compared to the old solid levers, the rollbar no longer folds down out of the way, instead it folds down just enough to walk right in to it with your forehead when you try to walk behind the tractor and finally the pedal to lock the differential is just a rod that only sticks out about an inch. I was told by my salesman that there is an aftermarket pedal you can get for the diff lock. When I ordered this tractor I did not see the new models, but I went with 2025r Instead a 1025r because I didn't want to go backwards, but compared to my 2320 it doesn't seem to live up to the standards. I was told that the 2320 was made by Yanmar for John Deere and that the 2025R is made directly by John Deere this is probably the most disappointing part!!

Location: Grand Rapids Michigan

Length of Ownership: 1month

Usage: Daily

I bought this tractor a month ago and traded in a 1025r it feels like more tractor and I love it very useful and works hard

Location: SE Wisconsin

Length of Ownership: 1month

Usage: Monthly

Very powerful little machine, it's great for getting into small places but is happy in wide open spaces as well.

Location: Blissfield, MI

Length of Ownership: 3months

Usage: Daily

I bought the 2025R a few months back to help with my bad back. It's exceeded my expectations. We added forks, a rototiller, and post hole digger and now can do nearly anything we want. We've also used the tractor to do things that we never even thought about. While I wouldn't hesitate to buy again, I'd probably go with the smaller 1025R. While the 2025R is more stabile and comfortable for me, the 1025R would fit into smaller spaces.

Location: Washington NC

Length of Ownership: 6months

Usage: Weekly

I’ve had the 2025 Tractor for about 5 months and I love it, has plenty of power and works hard, but has couple of things that can be improved: Seat Suspension needed for harsh ride, and needs a guide on the mower deck front attachment for when removing and installing deck with loader on tractor.

Location: Mississippi Gulf Coast

Length of Ownership: 3months

Usage: Monthly

I have owned the tractor for a few months. Already cleared a fence line, dug a drainage ditch, and mowed my creek property. Work perfectly.

Location:

Length of Ownership: 6months

Usage: Daily

i have a 2019 2025R with loader, backhoe, 54D mower, rear Frontier blower and other non-Deere implements. It is used on our large forested property for all types of regular (mowing, snow) and periodic (box blading, digging, etc.) tasks. Perfect machine for our size property and usage pattern. While the 1025R is similar and very capable, the tire size, height, clearance, weight, ground speed, and stability differences more than justify this machine in my opinion. With tractors, more power and size is almost always better but I have found you need to buy for your expected usage and realistic "peak" uses to avoid buyers remorse. I have read about many upgrades created by just slightly underbuying. This particular tractor feels like and for me is one that allowed me to feel very satisfied without looking up at the larger frame 2-series or entry 3-series with tractor envy. This is a very capable and relatively affordable machine.

Location: Olalla, WA

Length of Ownership: 3months

Usage: Weekly

This compact tractor and backhoe is the perfect size for my wife and I to operate and maneuver around our little place. The manual thumb of the backhoe is a MUST HAVE!!!

Location: Bloomer, WI

Length of Ownership: 1yearOrLonger

Usage: Weekly

We live on 35 acres with 30 of it rented to a local farmer. Originally purchased a 1025R, but it was just a little to small for what I was doing. The 2025 fits the bill perfectly.

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By