CP770

Cotton Picker

- 13.6 L, 555 HP engine

- Up to 20 mph transport speed

- 4.6 mph top harvest speed

- Up to 20% greater fuel efficiency1

- 8% reduction in wrap and hauling costs1

View Product Brochure

Features

Round modules

Round modules

CP770 harvesting cotton

CP770 harvesting cotton

The CP770 helps lower wrap and hauling costs by 8 percent per lint pound through denser and larger diameter round modules. The TamaWrap+™ round module wrap protects your cotton from the harvester to the gin.

- 5 percent denser round modules – The second-generation cotton handling system packs more seed cotton in each round module than the previous model, lowering your yearly wrap costs.

- 2 percent larger diameter round modules – The CP770 updated round module builder allows you to make round modules from 229 cm to 244 cm (90 in. to 96 in.) in diameter. This increase in diameter puts even more cotton in the same portion of module wrap. When adding up wrap cost savings from denser and larger diameter round modules, you enjoy a reduction in wrap and hauling costs up to 8 percent per lint pound.

TamaWrap+ is a trademark of Tama Plastic Industry.

CP770 harvesting cotton by day

CP770 harvesting cotton by day

CP770 harvesting cotton at night

CP770 harvesting cotton at night

John Deere knows how important it is for you to get your cotton out of the field to protect its quality. Therefore, harvest speeds were increased by 5 percent, transports speeds were increased by 18 percent, and the time to wrap and eject a module was reduced by 33 percent. All this means you can cover an extra 1.6 ha (4 acres) in a 10-hour harvest day.

- Deliver maximum harvesting productivity – The CP770 Cotton Picker features a 5 percent increase in sync speed (7.4 km/h [4.6 mph]) and scrapping speed (9 km/h [5.6 mph]), compared to the CP690 it replaces.

- Gentle crop engagement reduces cotton loss – The PRO16 HS row-units are equipped with high-speed stalk lifters that engage the cotton crop gently, even at higher harvest speeds. These crop lifters reduce boll loss when harvesting faster, meaning more cotton enters the row-unit to be harvested.

- Increased throughput with the Generation 2 cotton handling system – The next-generation module handling system cuts the module wrap-eject cycle time by 33 percent from 48 seconds to 32 seconds, allowing you to stay at harvest speed in higher yielding cotton while making every harvest day more productive.

- Transport faster between fields – You and your operators will appreciate the increased transport speed with the ProDrive™ transmission. You can run from field to field at 32.2 km/h (20 mph), an 18 percent increase over the CP690.

PRO16 HS row-units

PRO16 HS row-units

CP770 Cotton Picker harvesting cotton

CP770 Cotton Picker harvesting cotton

The C770 Cotton Harvesters were designed to make you more productive while reducing fuel costs by up to 20 percent per lint pound of seed cotton harvested. Teamed with the engine, the variable pitch reversible fan uses less power, and the updated hydraulic system is more efficient - all contributing to the reduction in fuel usage.

- 20 percent better fuel efficiency per lint pound of seed cotton harvested – Run 12 hours without stopping for fuel and enjoy fuel savings up to 20 percent or more as measured in gallons per lint pound. The John Deere JD14P 13.6L (830-cu in.) engine runs at 1900 rpm during harvest, reducing fuel usage, noise, and wear.

- Reduce cooling power requirements – Variable pitch fan blades automatically adjust to cooling needs, reducing the horsepower needed to cool the radiators. By adjusting the angle of the cooling fan blades, the airflow is reversed to clean the radiators without operator input, keeping you more productive harvesting your crop.

- Dry sump hydraulic system reduces parasitic loss – The updated hydraulic system features a dry sump design that reduces parasitic loss to improve fuel efficiency. Another feature of this system you will appreciate is the ease of checking hydraulic oil level in one location compared to three separate locations on the previous harvester.

Gen 4 4600 CommandCenter™ Display

Gen 4 4600 CommandCenter™ Display

C770 cab with integrated technology

C770 cab with integrated technology

Make informed decisions during harvest with the integrated technologies in the C770 Cotton Harvesters. This technology automatically transfers harvest data to your John Deere Operations Center™ account where you can analyze, manage, and share data with your trusted partners to make profitable business decisions.

- Real-time yield feedback in the cab and on mobile devices with yield Documentation – Monitor harvest progress on the Gen 4 4600 CommandCenter Display inside the cab and on your mobile device through John Deere Operations Center. Documentation is standard equipment on the C770 Cotton Harvesters, and the information is provided in real time so you can keep tabs on your progress all throughout the harvest season.

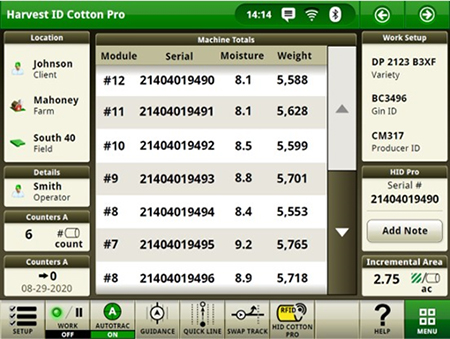

- Track round modules from the cab with Harvest Identification, Cotton Pro – You will appreciate the Harvest Identification, Cotton Pro (HID, Cotton Pro) dedicated run page and interaction on the Gen 4 4600 CommandCenter Display. This system is easier than ever to use, sends data to your John Deere Operations Center account in almost real time, and allows you to track round module weight and moisture from inside the cab.

- Premium Activation 3.0 – The C770 Cotton Harvesters can cover over 40.5 ha (100 acres) in a single day. AutoTrac™ RowSense™ system bolsters the formidable manual RowSense system to provide a superior hands-free harvest operation where the operator can focus on field and machine functions and not worry about where the machine is tracking in the field. Also, when you have more than one harvester in the field, In-Field Data Sharing allows up to six harvesters to share data (such as coverage maps) so they can all plan their harvest paths without interruption. Finally, Data Sync provides a consistent transfer of machine and harvest data to the John Deere Operations Center where you can manage your farm with ease, whether you are in the field with the harvester or in your office.

- Send data to your home office, dealer, or trusted partners – All C770 Cotton Harvesters come with JDLink™ connectivity, which automatically sends yield maps, HID, Cotton Pro, and other harvest data to the Operations Center for later analysis. From your office, JDLink gives you a look at all your machines – where they are, how they are performing, and what action you can take to improve your harvest.

- Generate, collect, and analyze all your harvest data easier than ever with John Deere Operations Center - Operations Center makes it easier than ever to view, analyze, and compare different map layers and print out reports to make next year’s harvest even more profitable. Plus, you have access to more than 100 connected software tools, and you can easily share your harvest data with your trusted partners to help you make better decisions.

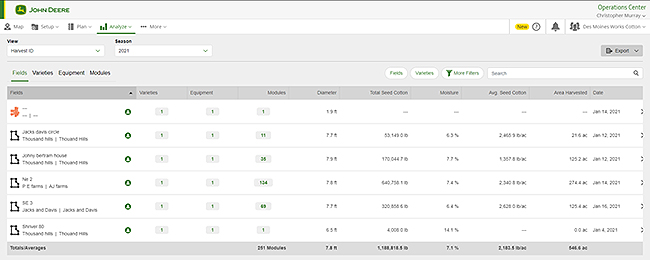

John Deere Operations Center provides easy-to-use tools to store, analyze, manage, and share your cotton production system data. Updates to John Deere Operations Center, such as the Analyze tool, make it easier than ever to visualize and manage the data from Harvest Identification, Cotton Pro.

HID, Cotton Pro data in the Analyze tool

HID, Cotton Pro data in the Analyze tool

Harvest Identification, Cotton Pro on Gen 4 4600 CommandCenter™ Display

Harvest Identification, Cotton Pro on Gen 4 4600 CommandCenter™ Display

Harvest Identification, Cotton Pro (HID, Cotton Pro) ensures each of your round modules are tracked from the field and the information is available to share with your trusted partners, such as your cotton ginner, seed sales representative, and agronomist. This information also helps with logistics from field to gin.

- View every round module made in your fields – HID, Cotton Pro tracks each round module harvested in your field and provides pertinent information on the HID, Cotton Pro run page. You can easily track moisture and weight for each module and make decisions on when to start and end harvest to protect your cotton quality.

- Add a note to a module with a touch of a button – Adding a note to a module is easier than ever with the touch of a button on the HID, Cotton Pro run page. These notes are documented and shared with the cotton gin when your HID, Cotton Pro data is shared from John Deere Operations Center.

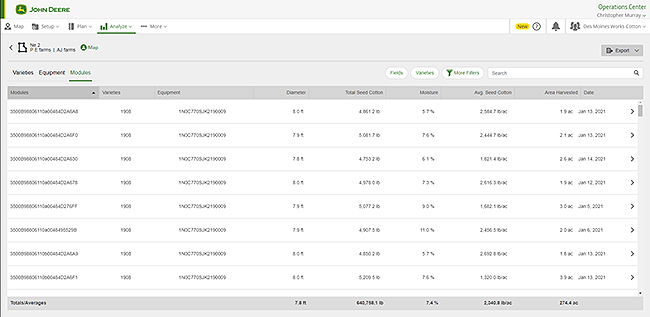

- Easily view module attributes with John Deere Operations Center – John Deere offers multiple tools to manage, visualize, and share your cotton production systems data in John Deere Operations Center. Utilize the Analyze tool to view a macro level pivot table of HID, Cotton Pro data for all your fields, or dig in deeper and see how each module in each of your fields performed. You can view your yield data and HID, Cotton Pro data in Field Analyzer Beta where each module is displayed in its creation location in each field. This tool is a great resource to share with trusted partners.

HID, Cotton Pro data in the John Deere Operations Center Analyze tool

HID, Cotton Pro data in the John Deere Operations Center Analyze tool

CP770 right-hand platform

CP770 right-hand platform

CS770 right-hand platform

CS770 right-hand platform

Daily maintenance and cleaning are easier than ever on the C770 Cotton Harvesters. You will appreciate the full access doors on the power module, extended platforms, and easy-open belly shields – all features to reduce the time it takes to maintain and clean the harvester.

- Reduce time spent cleaning the harvester – Your time is important, and John Deere listened to your feedback in making the harvester easier to clean. You will appreciate all the changes to make cleaning faster than the C690 Harvesters, especially the easy-to-open belly shields that are opened by two levers from ground level.

- Easy daily maintenance – Checking oil is easy with a convenient single hydraulic oil sight gauge and a large access door for the engine oil dipstick. Additional service lights are positioned to provide extra visibility when cleaning and performing maintenance.

C770 easy-open belly shields

C770 easy-open belly shields

C770 cab

C770 cab

Leather seat inside of cab

Leather seat inside of cab

All C770 Cotton Harvesters provide a quiet, comfortable ride with visibility, control, and convenience unmatched in the industry. Choose from two Comfort and Convenience packages to find a cab that fits you best.

- 30 percent larger cab offers more room and a quiet oasis during harvest – The cab on the C770 Cotton Harvesters is 30 percent larger than the cab on the C690 Harvesters. You’ll love the convenience of five cup-holders, an accessory rail with an iPad® tablet mount, USB and power outlets, and closed storage. Also, you will find this is the quietest cab ever offered on a John Deere cotton harvester, quiet enough to take a phone call without worry.

- Leather seat with massage, heating and cooling, electronic controls, and increased swivel (up to 16 degrees left and right) – When you sit down in the plush leather seat, the long days and nights won’t seem so long. Activate the heating or cooling features to make your time in the seat even more enjoyable, but don’t forget about the massaging feature. This feature makes sure your muscles never get sore so that at the end of the day, you are as refreshed as when you started harvest.

- Smooth out 90 percent of vertical movements with ActiveSeat™ equipment suspension – The electric motor responds instantly to the ruts, bumps, and jolts, delivering an unbelievably comfortable ride. While you’re harvesting more acres per hour, you’ll stay refreshed and alert.

- Get unmatched visibility – The 360-degree light-emitting diode (LED) lighting package turns night into day, making harvesting during the night a pleasure. There are front and right-hand side wipers to clean the windows when they become dusty. Two factory-installed cameras are included (one rear facing and one mounted in the round module builder) with the option of adding two extra cameras to provide the ultimate visibility during harvest.

C770 window wipers

C770 window wipers

iPad is a trademark of Apple Inc.

Specs & Compare

Offers & Discounts

Reviews

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By