W61R

Commercial Walk-Behind Mower

- 61-inch (155-cm) floating mower deck

- Powerful 23.5 hp (17.5 kW) V-twin engine

- Self-propelled hydrostatic drive system

- Easy-to-use controls for operator comfort and convenience

Starting At:

$11,689.00

Request a Demo

Features

Air-cooled engine, right front view

Air-cooled engine, right front view

Air-cooled engine, left side

Air-cooled engine, left side

Powered by an air-cooled, vertical-shaft engine:

- 15.5 hp (11.6 kW) FX481V - W36R

- 19.0 hp (14.2 kW) FX600V - W48R, W52R

- 23.5 hp (17.5 kW) FX730V - W61R

- 36.8 cu in. (603 cc) - W36R, W48R, W52R

- 44.3 cu in. (726 cc) - W61R

- Electric start with a large 300 cold-cranking amp (CCA) battery for fast, convenient starts

- V-twin design for smooth operation and fast starts

Consistently strong torque at low- or high-speed operation

- Aluminum engine block with cast-iron cylinder liners

Effectively dissipates heat

- Lightweight and strong construction

- Overhead valve design

- More horsepower and torque per cubic inch of displacement

-

- Better fuel efficiency

- Less oil consumption

- Cooler operating temperature

- Full-pressure lubrication with full-flow filter

- Reduces engine wear by ensuring proper lubrication, even when operating on hillsides or uneven terrain

- Helps keep oil clean for increased engine life

Heavy-duty canister air cleaner

Heavy-duty canister air cleaner

Cylinder-head cooling-fin cleanout ports

Cylinder-head cooling-fin cleanout ports

- Heavy-duty canister air cleaner for extended engine life and efficient operation

- Single-element air filter (W36R, W48R, W51R) or dual-element air filter (W61R)

- Rotating grass chopper screen

- Cylinder-head cooling-fin cleanout ports to ease maintenance

- Complies with U.S. Environmental Protection Agency (EPA) emission standards

Fuel tank and battery

Fuel tank and in-line fuel filter

Fuel tank and in-line fuel filter

Battery

Battery

Large, 5.4-gal. (20.4-L) top draw fuel tank is easy to fill with large filler opening in an easy-to-reach location.

- Fuel pump for dependable, consistent operation

- Top-draw system to reduce the chance for fuel leakage

- A replaceable in-line fuel filter for trouble-free operation

A powerful, 300-CCA battery is secured and protected from damage in an easy-to-access location.

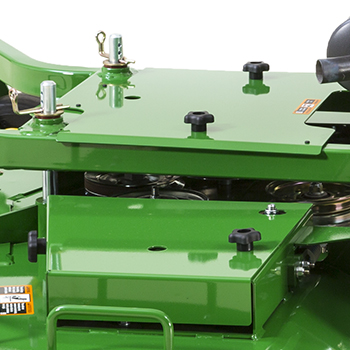

W61R mower deck

W61R mower deck

W61R mower deck

W61R mower deck

John Deere commercial mower decks have always demonstrated quality, performance, and durability. Each commercial walk-behind mower is equipped with a high-quality fabricated mower deck:

- 10-gauge, 0.135-in. (3.42-mm) fabricated steel deck top with added 10-gauge, 0.135-in. (3.42-mm) spindle mounting plate

- 7-gauge, 0.19-in. (4.8-mm) side skirts with reinforcement bar

The fabricated, floating mower deck delivers an extremely high-quality cut in diverse conditions:

- Floating suspension enables the best possible cut.

- Reinforced front lower edge provides strength and durability.

- Four mower front wheels are double-captured for durability and adjustable to three positions to suit the cut height.

- Two-coat paint covering protects the mower deck and resists corrosion.

- Deep-deck design for superior capacity.

- Side and center anti-scalp wheels promote a smooth mowing job.

Mower deck underside (similar W48M mower shown)

Mower deck underside (similar W48M mower shown)

Rear mower wheel

Rear mower wheel

- Hardened steel blades extend cutting time and increase durability.

- High blade-tip speed of approximately 18,000 fpm (5,486 m/min) for more blade strikes per inch mowed.

- R Series mower decks include a rear wheel for additional anti-scalp protection.

- Adjustable to three height positions to suit the cut height

Flexible mower-discharge deflector

Flexible mower-discharge deflector

Inset caster wheels

Inset caster wheels

A high-quality polyethylene deflector gives an excellent finished appearance:

- Wide, formed discharge deflector provides even clipping distribution.

- Large discharge deflector evenly disperses expelled clippings.

Caster wheels with flat-free tires contribute to a smooth, even cutting job:

- Large, flat-free caster wheels carry the mower deck smoothly over the lawn.

- Caster wheels are close to the mower deck to reduce vehicle footprint and turning radius.

- With the wheels less exposed, there is less chance they will get snagged by immovable obstacles, thus improving maneuverability and reducing chance of damage.

Mower cut-height adjustment

Mower cut-height adjustments

Mower cut-height adjustments

Mower cut-height adjustment clip

Mower cut-height adjustment clip

A floating mower deck has several advantages over a fixed mower deck design:

- Follows ground contour more effectively for a more even cut

- Travels smoothly above the ground with minimal chance of scalping

- Easier to adjust the cutting height

Mower cutting height can be set from 1.5 in. (3.8 cm) to 4.5 in. (11.4 cm) in 0.5-in. (1.3-cm) increments:

- The free-floating deck gives a smoother, more level cut.

- Height-of-cut changes can be made without tools.

- Large handles are provided to facilitate lifting the mower deck for setting the cut height.

- Cut-height adjustment pins have 90-degree bend for easy removal and reinstallation.

Mower shields in place

Mower shields in place

Easy-to-remove mower deck shields

Easy-to-remove mower deck shields

Mower deck shields are easily removed with hand knobs for access to the drive belt and other service points:

- Easy-attach belt shields allow for quick access for service.

- Four hand knobs allow removal of both mower shields.

- Greaseable spindles with easy, top access for simplified servicing.

- Spindle grease fittings can be greased with shields in place.

Optional mulching attachment

Optional mulching kit and blades (similar design shown)

Optional mulching kit and blades (similar design shown)

An optional mulching attachment and special mulching blades are available:

- The high-performance mulching attachment includes formed steel baffles to control the material for superior performance.

- Special mulching blades can also be used for side discharging, though overall cutting performance may be slightly less than with the standard blades.

Optional mulching kit and blades (similar design shown)

Optional mulching kit and blades (similar design shown)

An optional mulching attachment and special mulching blades are available:

- The high-performance mulching attachment includes formed steel baffles to control the material for superior performance.

- Special mulching blades can also be used when side discharging, though overall cutting performance may be slightly less than with the standard blades.

- The mulching attachment allows for conversion of the mower deck so it can be used to perform the mulching function (grass or leaves).

Operating tips when mulching:

- Mow when grass is dry.

- Observe the one-third rule.

- No more than one-third of the grass blade should be cut off at one time. This allows more efficient mulching and will promote the continued good health of the grass.

- If the desired cut height cannot be achieved by cutting off one-third, or there is clumping of the clippings, it may be required to cut higher, wait a day, then lower the mower and make a second pass.

- Mow at proper intervals, approximately every four to five days.

- Always mow with sharp blades.

- Adjust ground speed to allow the mower deck to process the clippings effectively.

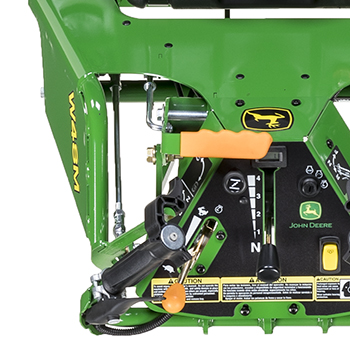

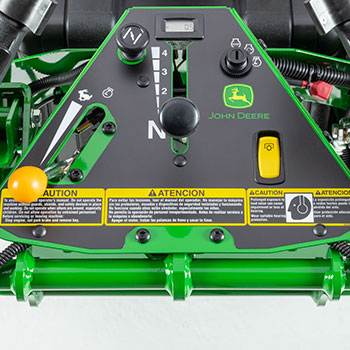

Operator station (R Series shown)

Operator station (R Series shown)

Compact control console (R Series shown)

Compact control console (R Series shown)

All of the controls are located within comfortable reach of the operator. Simplified operation of each control offers superior convenience, productivity, and safety:

- Color-coded and clearly marked levers, switches, and buttons enable simplified operation.

- Bilingual decals in English and Spanish are provided.

- The operator presence system requires that one of the bails must be depressed to operate the unit; the machine must be in neutral and the power take-off (PTO) must be disengaged to start.

- Operator presence control levers are recessed into control handle when engaged, provides a smooth contour and comfortable handle to hold during operation.

- Separate choke and throttle – This takes the guesswork out of choke operation, with less chance of fowling the spark plugs.

- Electric PTO clutch on the engine powers the mower deck. The PTO switch on the dash is easy to see and use.

Steering control locked in neutral position

Steering control locked in neutral position

Steering levers control speed and direction in use

Steering levers control speed and direction in use

- Speed and steering controls are designed for ease of operation.

- Ergonomically designed control configuration on all units gives good operator comfort and leverage while driving.

- A speed-control lever is conveniently located in the center of the console and used to set maximum desired speed.

Operator presence control handle in use

Operator presence control handle in use

- Low actuation force is required for operator comfort.

- The neutral lock is spring-loaded for easy release.

Electric PTO switch

Electric PTO switch

Electric PTO clutch

Electric PTO clutch

A convenient and easy-to-operate switch is located on the console to operate the electric clutch, which powers the mower deck.

Parking brake (W36M, W48M)

Parking brake lever, W48M shown

Parking brake lever, W48M shown

W36M and W48M parking brake control lever:

- Color coded and located above the console, within easy reach of the operator

- Actuates internal braking mechanism of the transmissions

Parking brake (W36R, W48R, W52R, W61R)

Left brake pawl and color-coded parking brake control

Left brake pawl and color-coded parking brake control

Right brake pawl, W48R shown

Right brake pawl, W48R shown

W36R, W48R, W52R, and W61R parking brake control lever:

- Color coded and located above the console, within easy reach of the operator

- Actuates arm that creates a mechanical locking interference on both drive tires

- Brake pawl located near top of tire to eliminate contact with curbs

Bumper-to-bumper warranty

Model |

Warranty |

W36M, W48M |

24 months no hour limitation |

W36R, W48R, W52R, and W61R |

36 months or 1200 hours, whichever comes first First 24 months, no hour limitation |

John Deere warranty includes:

- Single source

- Commercial application

All parts, except tires and batteries (which are warranted under separate documents provided with each product), are warranted

Quick response (QR) codes link to owner information web pages

QR code label on M-Series frame

QR code label on M-Series frame

QR code label near R-Series handlebars

QR code label near R-Series handlebars

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located on frame (M-Series) or near handlebars (R-Series). The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

Engine service

Engine service points, W48R engine shown

Engine service points, W48R engine shown

Engine cleanout port cover removed, W48R shown

Engine cleanout port cover removed, W48R shown

Engine service points are easy to reach:

- Oil drain tubes are provided to reduce oil spills and mess.

- Cleanout ports make inspecting and cleaning engine cooling fins easy.

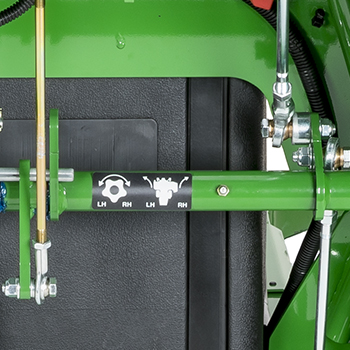

Durable and adjustable control linkage

Control rods with adjustable ends

Control rods with adjustable ends

Plated and adjustable control rods and ends

Plated and adjustable control rods and ends

Control rods and ends are plated to stop rust and corrosion:

- Large pivot points for minimal wear and long life

- Grease fittings to lubricate for continued smooth operation

- Adjustable rod ends for easy and accurate adjustments

Control linkage protected when nesting equipment

Control linkage protected when nesting equipment

Control linkages are positioned tightly to the main frame structure to protect them from damage, such as being bent that could impact the speed and tracking of the unit.

Transmission service

Transmission oil reservoir, W36M shown

Transmission oil reservoir, W36M shown

Replaceable transmission oil filter, W52R shown

Replaceable transmission oil filter, W52R shown

Transmission oil reservoirs are easy to access and fill.

The transmission oil filter is a replaceable spin-on type for easy service.

Tow release

Transmission tow-release, M Series design

Transmission tow-release, M Series design

Hydraulic bypass valve, R Series design

Hydraulic bypass valve, R Series design

Transmission tow valves are easy to find and use.

Convenient tie-down locations

Front tie-down points

Front tie-down points

Rear tie-down points

Rear tie-down points

- Front and rear tie-down points are provided to aid in transport.

- More-rounded corners contribute to a clean, attractive appearance.

- Greater strength results from eliminating sharp angles where peak loads can cause failure.

W48R showing compact design, overhead

W48R showing compact design, overhead

W52R showing compact design, left

W52R showing compact design, left

From the operator's station to the mower deck, John Deere walk-behind mowers have a compact and functional design:

- Caster wheels are set in as close to the mower as possible.

- Shortest overall machine length to maximize maneuverability and minimize space needed on a trailer

- The compact design of John Deere commercial walk-behind mowers allows access to operate in tight areas where larger ride-on machines cannot fit. Often, this means the area can be mowed with a walk-behind mower so it is not necessary to switch to another mower, which helps reduce the time on site.

- With the compact design of John Deere commercial walk-behind mowers, less space is required on a truck or trailer, possibly freeing up space for an extra mower, resulting in less time on property, saving both time and money.

W61R mower deck, right

W61R mower deck, right

W48M Mower

W48M Mower

Whether mowing hills or on level terrain, trimming, or mowing straight-away, the operator of a John Deere commercial walk-behind mower is able to control the machine:

- The compact design makes the machine easier to maneuver.

- Caster wheels are set close to the blades for most effective ground following capability.

- Compact design takes less space for mowing tighter areas.

Heavy-duty frame

Mower frame, front

Mower frame, front

R Series mower frame, rear

R Series mower frame, rear

John Deere commercial walk-behind mowers are designed around a heavy-duty formed and welded steel frame for strength and reliability:

- Welded frame consists of a combination of tubes and plate steel for a continuous frame that delivers long life

- Yoke and caster wheel assemblies are built strong for long life

Convenient tie-down locations

Front tie-down points

Front tie-down points

Rear tie-down points

Rear tie-down points

Front and rear tie-down points are provided to aid in transport.

- Allows ability to secure straps pulling in opposite directions to keep unit from rolling during transport.

Wheels and tires

Front caster wheel, W48R shown

Front caster wheel, W48R shown

Rear drive wheel, W48R shown

Rear drive wheel, W48R shown

Large, flat-free front caster wheels and 4-ply rear drive wheels provide smoother operation:

- Rear tires are sized for the machine and mower width to give optimum deck overhang for trimming performance.

- Tire size

- 18x6.5-8 (W36M, W36R)

- 18x8.5-8 (W48M, W48R, W52R, W61R)

- Benefits include:

- Better slope performance

- Easier to operate over uneven ground

- Better traction

- Increased ground clearance

- Front caster wheels are designed for the best performance.

- Large, 9x3.5-4 size for good flotation and easy steering

- Flat-free, semi-pneumatic design for reliability

- Positioned back close to the mower deck for most effective ground following capability

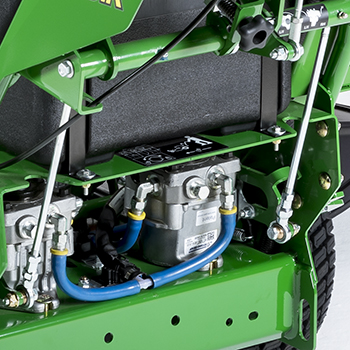

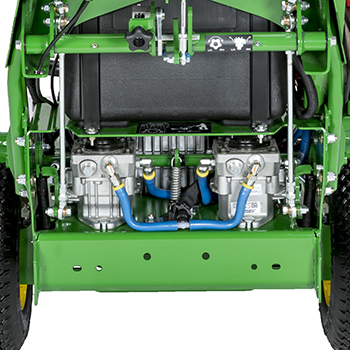

R Series drive system

R Series drive system

W36R, W48R, W52R, and W61R Mowers are equipped with an infinitely variable hydrostatic drive system with reverse, which does the following:

- Provides infinite ground-speed adjustments from 0 mph to 7.5 mph (0 km/h to 12.1 km/h) to meet the mowing application

- Enables a smoother transition from one speed to another

- Gives a reverse speed of 3 mph (4.8 km/h), enabling the operator to back out of tight mowing areas and increase productivity

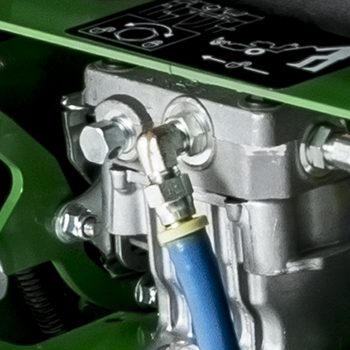

Wheel motor and steel oil tubes

Wheel motor and steel oil tubes

Transmission oil reservoir

Transmission oil reservoir

Wheel motors power the rear drive wheels. Steel oil tubes between the pumps and wheel motors are used for maximum reliability.

A transmission oil reservoir is located next to the fuel tank for easy checking.

Sight glass for checking oil level without opening hydraulic system minimizes risk of contamination entering the system.

Replaceable transmission oil filter

Replaceable transmission oil filter

The transmission oil filter is a replaceable spin-on type for easy service.

Operator presence system

Operator presence system

Right speed control lever and neutral lock

Right speed control lever and neutral lock

Safety features are designed into M and R Series commercial walk-behind mowers:

- Before the engine will start, the transmission speed control lever must be locked in neutral, the parking brake set, the power take-off (PTO) disengaged, and the key switch turned to the on position.

- Left- and right-hand speed/direction control levers are locked in neutral by spring-loaded knobs on the end of control handles.

- The knob has a finger lever, making it easy to move to the locked position while holding the control lever in the neutral position.

- The locking knob is spring loaded for easy release of the control levers.

- Separate choke and throttle – this takes the guesswork out of choke operation, and there is less chance of fouling the spark plugs.

- Color-coded and clearly marked switches and buttons are easy to find.

Parking brake lever (W48R shown)

Parking brake lever (W48R shown)

Key switch

Key switch

- Convenient parking brake location

- The key switch interlock prevents bypass starting

Mower deck shields

Mower deck shields

Control panel

Control panel

- Shields are easy to remove and reinstall so they are more likely to be put back on after removal

- Safety labels

- Bilingual decals in English and Spanish

Specs & Compare

Key Specs | W61R Current Model |

| Engine manufacturer/model | FX730V |

| Engine power | At 3600 rpm 23.5 hp* 17.5 kW |

| Fuel tank capacity | 5.4 U.S. gal. 20.4 L |

| Mower deck Size | 61 in. 155 cm |

| Blade tip speed | Approximately 18,000 fpm 5,486 m/min |

| Transmission | Two Hydro-Gear™, 0.73-cu in. (10-cc) hydraulic pumps and Danfoss 12 cu-in. (197-cc) wheel motors and ergonomic handles with spring loaded neutral lock |

| Speed range | Forward, 0-7.5 mph 0-12.1 km/h Reverse, 0-3 mph 0-4.8 km/h |

| Drive wheels | 18x8.5-8 |

| Caster wheels | 9x3.5-4 semi-pneumatic |

| Warranty | 36 months or 1200 hours, whichever comes first: First 24 months, no hour limitation |

Engine | |

| Manufacturer/model | FX730V |

| Power | At 3600 rpm 23.5 hp* 17.5 kW |

| Displacement | 44.3 cu in. 726 cc |

| Cylinders | V-twin |

| Crankcase capacity | With filter, 2.2 U.S. qt |

| Operating speed | 3,600 rpm |

| Idle Speed | |

| Ignition/Starter | Electronic/electric start |

| Valving | Overhead V-valve |

| Oil filter | Standard |

| Lubrication | Full pressure |

| Governor | Flyweight all speed governor |

| Hour meter | Standard, digital |

| Cooling system | Air cooled |

| Air cleaner | Heavy-duty canister type with safety element |

| Muffler | Low tone |

Fuel System | |

| Fuel type | Gasoline |

| Fuel tank capacity | 5.4 U.S. gal. 20.4 L |

| Fuel pump | Vacuum-operated diaphragm |

| Fuel delivery system | Carburetor |

| Fuel tank switch/Shut off valve | No |

| Filler neck opening | |

| Fuel pickup | Top draw |

Electrical System | |

| Ignition | Electronic spark |

| Hourmeter | Standard, digital |

| Operator presence starting system | PTO off, park brake engaged, speed lever in neutral |

Drivetrain | |

| Transmission | Two Hydro-Gear, 0.73-cu in. (10-cc) hydraulic pumps and Danfoss 12 cu-in. (197-cc) wheel motors and ergonomic handles with spring loaded neutral lock |

| Wheel motors | Danfoss 12 cu in. 197 cc |

| Shift mechanism | Ergonomic handles with spring-loaded neutral lock |

Tires | |

| Drive wheels | 18x8.5-8 |

| Outside to outside tire measurement | |

| Caster wheels | 9x3.5-4 semi-pneumatic |

| Shift mechanism | |

Travel Speed | |

| Forward speeds | Infinite |

| Reverse speeds | Infinite |

| Speed range | Forward, 0-7.5 mph 0-12.1 km/h Reverse, 0-3 mph 0-4.8 km/h |

Brakes | |

Dimensions | |

| Height | 44.8 in. 114 cm |

| Length with deck | 83 in. 211 cm |

| Width | Deflector down - 75 in. 191 cm Deflector up for storage - 65 in. 165 cm |

| Weight | 785 lb 356 kg |

Mower Decks | |

Buyer's note | |

Additional information | |

Offers & Discounts

Reviews

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By