RB21 Series

Rear Blades

- Angle adjustment

- Reversible cutting edge

- Optional end plates

- Hydraulic cylinder kit

View Product Brochure

Features

Turntable angle adjustment

Turntable angle adjustment

The turntable on the RB10, RB11, and RB21 Series Rear Blades makes it possible to adjust the angle to four different positions in both forward and reverse for those extra-tedious jobs.

Manually adjusting the blade forward makes it easy to handle leveling needs in a variety of soil conditions. Swing the blade around and use it to backfill or clear debris or snow.

Tubular steel frame

Tubular steel frame

The tough, tubular steel frame on Frontier™ RB Series Rear Blades is perfect for grading. Its full-radius moldboard more than handles landscaping needs.

NOTE: This applies to all RB Series Frame except the RBL Series.

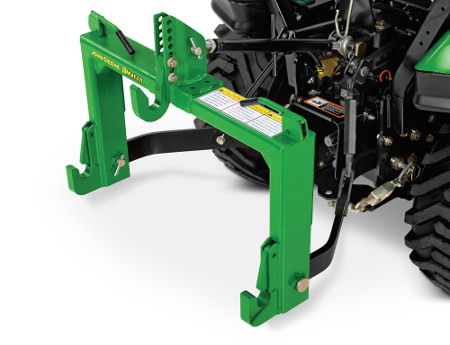

Hitch on RB10, RB20, and RB21 Series Rear Blades

Hitch on RB10, RB20, and RB21 Series Rear Blades

The Frontier™ RB10, RB20, and RB21 Series Rear Blades are all iMatch™ quick-hitch compatible and compatible with Category 1 hitches. Both systems provide a quick, efficient hookup.

Frontier™ rear blade cutting edge

Frontier™ rear blade cutting edge

All Frontier RB Series Rear Blade cutting edges are reversible, featuring bevels on both edges to give the blade twice the work life.

End plate option on RB24 Rear Blade

End plate option on RB24 Rear Blade

End plate option on RB24 Rear Blade

End plate option on RB24 Rear Blade

End plates on RB23 Rear Blade

End plates on RB23 Rear Blade

End plates allow Frontier™ RB Series Rear Blades to hold more material while dragging it from place to place. This is ideal for leveling uneven terrain.

Each of the field conversion kits are for a pair of end plates and prevent the blades from windrowing material when backfilling or leveling.

Figure 1 Shown on RB24 Series

Figure 1 Shown on RB24 Series

Skid shoes increase the life of the cutting edge on all RB Series Rear Blades and avoid damaging the work surface while cleaning corrals or plowing snow.

NOTE: Skid shoe style shown in image above used with RB2060, RB2072, and RB2084 models.

The skid shoe kits include one pair and allow the blade to ride on the shoes at a set height to allow the operator control of the blade depth.

The bundles listed below identify the rear blades they fit.

Hydraulic cylinder on RB23 Rear Blade

Hydraulic cylinder on RB23 Rear Blade

The field-conversion hydraulic cylinder kit includes one cylinder. This kit allows the operator to position the blade without having to get off of the operator's station.

NOTE: A rear selective control valve (SCV) is required.

Specs & Compare

Dimensions | RB21 Series Current Model |

| Width in working position | 1.5 m 5 ft |

| Moldboard length | 152.4 cm 60 in. |

| Moldboard height | 43.2 cm 17 in. |

| Moldboard thickness | 0.6 cm 0.25 in. |

Weight | |

| Machine | 177.8 kg 392 lb |

| Shipping per unit | 193.2 kg 426 lb |

Tractor requirements | |

| PTO hp (kW) | Max: 2WD - 48.5 kW 65 hp Max: 4WD - 44.7 kW 60 hp |

| Hydraulic offset kit (hoses and fittings included) | |

Angle, tilt, offset, pivot | |

| Pivot angle degrees | 360 degree (angle) |

| Angle forward, number of positions | Three positions, on each side up to 53 degree (angle) |

| Angle reverse, number of positions | Three positions, on each side up to 53 degree (angle) |

| Tilt positions/degrees | Three positions, up to 22 degree (angle) up or down |

| Offset position left or right | 15.2 or 30.5 cm 6 or 12 in. |

Hitch | |

| Type | Cat. 1 |

| Quick hitch compatibility | iMatch compatible (quick-attach system) |

Reversible cutting edge | |

| Thickness | 1.3 cm 0.5 in. |

| Height | 15.2 cm 6 in. |

Duty | |

Parking stand | |

Set-up time | |

Warranty | |

Additional information | |

Offers & Discounts

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By