5075E

Utility Tractor

- 2WD or MFWD

- 5-year Powertrain warranty*

- Available in premium cab, standard cab or open operator station

- No Regen required

View Product Brochure

Features

5E 3-Cylinder Premium Cab offers enhanced comfort and value

5E 3-Cylinder Premium Cab offers enhanced comfort and value

5E 3-Cylinder Premium Cab

5E 3-Cylinder Premium Cab

Jobs seem easier when you are comfortable and the premium cab on the 5E 3-Cylinder Tractor is designed for you to enjoy. No matter the weather, the Premium Cab is ready for you to climb in and explore the value in the same-sized utility tractor to get the job done. With exclusive features like sunroof with sunshade, Electronic Quick Raise-Lower (EQRL) hitch controls, Go-Home Lighting, and loaded with features that are extras on a standard cab, this 5E Cab has lots to experience.

- Controls at your fingertips including the ergonomic controls on the right-hand console

- Smooth ride for any operator by adjusting the air suspension seat to the operator's weight and height

- Training new operators is easier with the instructional seat that can be folded away when not in use

- Listen to music or make hands-free calls with included Bluetooth radio and microphone

- See clearly out the back window thanks to rear windshield wiper and washer

- Light the night with LED headlights and work lights for improved visibility

- Gain visibility above roof line when stacking bales or let in air on a nice day with sunroof

- Access through right-hand door makes grabbing items from cab easy from either side

- Exit the cab and find your way home or to the truck thanks to go-home lighting

- Effortlessly shut the rear window with the improved grab handle

NOTE: Auxiliary power strip field kit shown is not included in Premium Cab image at top left.

| Compare features offered in 5E 3-Cylinder Premium Cab versus Standard cab: | ||

Features |

Standard Cab |

Premium Cab |

Sunroof with sunshade |

--- |

Exclusive |

Front and rear LED work lights |

--- |

Exclusive |

Go-home lighting |

--- |

Exclusive |

EQRL - Electronic Quick Raise/Lower: right hand console mounted |

--- |

Exclusive |

USB and auxiliary audio port |

--- |

Exclusive |

Rear window pull handle |

--- |

Exclusive |

Instructional seat |

Extra |

X |

Bluetooth radio with microphone |

Extra |

X |

Two rear SCVs |

Extra |

X |

Rear window wiper with washer |

Extra |

X |

Right-hand door and steps |

Extra |

X |

Tilt and telescopic steering column |

With PowrReverser™ |

X |

Cloth seat with retractable seat belt |

Mechanical seat suspension |

Air ride seat suspension |

Single rear SCV |

X |

X |

Air conditioning and heater |

X |

X |

Convenience power outlet |

X |

X |

LED headlights (high and low beam) |

X |

X |

Three-position (on/off/auto) interior dome light |

X |

X |

Right-hand console ambient lighting |

X |

X |

Beverage holders |

X |

X |

Sun visor |

X |

X |

Rearview mirror |

X |

X |

Two mounting bosses for monitors or accessories on B-pillar |

X |

X |

Radio ready (antenna cable, two speakers, and wiring harness) |

X |

X |

Front windshield wiper with washer |

X |

X |

Amp-style, three-socket power connector |

X |

X |

Stationary PTO enable switch |

X |

X |

Climate controls and rearview mirror

Climate controls and rearview mirror

5E 3-Cylinder Premium Cab with EQRL

5E 3-Cylinder Premium Cab with EQRL

Radio and rear window grab handle

Radio and rear window grab handle

Visibility to hook up rear implements

Visibility to hook up rear implements

Land planning with Frontier LP1184

Land planning with Frontier LP1184

Mowing with MX7

Mowing with MX7

Moving bales with rear bale spear

Moving bales with rear bale spear

Easily perform repeatable raising and lowering of the rear hitch with EQRL

Easily perform repeatable raising and lowering of the rear hitch with EQRL

Simplify repetitive rear hitch lifting and lowering tasks with the Electric Quick Raise Lower (EQRL) on 5E 3-Cylinder Premium Cabs. EQRL uses one button to raise to transport height and another to lower the rear hitch back to your prescribed depth.

- Reduce effort performing raise/lower functions of rear hitch

- Save time setting the prescribed depth and consistently returning to it

- Accurately maintain depth or lift height

- Comfortably complete repeatable tasks with ergonomic controls at your fingertips and proximity to other common controls like throttle, PTO, and MFWD engagement

EQRL efficiency gains:

- Moving bales – keeping your rear bale spear depth perfectly set to align to the center of the bale then raise to transport height

- Disking/Mowing – raise mower when making turns and return to desired height

- Box Blade/Land planning – creating smooth surfaces for your driveway or field

- Snow blading/blowing – reduce the risk of damaging driveways and roads

EQRL buttons work in tandem with rear hitch depth control and top-link load sensing draft control levers

EQRL buttons work in tandem with rear hitch depth control and top-link load sensing draft control levers

When parking after a long day or in a dark shed

When parking after a long day or in a dark shed

Go-Home lighting lights your path

Go-Home lighting lights your path

Overview

When leaving the field or parking the tractor in the shed, Go-Home lighting will provide light as you make your way to your vehicle or house. Included with the Premium Cab on 5E 3-Cylinder tractors.

- Allow for 30 seconds of light after the engine is shut off when Go-Home lighting is activated

- Avoid battery drain with automatic shut off headlights

Through the following steps, the go-home lighting is engaged:

- Park the tractor

- Move the key to off position

- Press the Go-Home Lighting button within 15 seconds

After pressing Go-Home Lighting button, the go-home feature is activated (headlight turns on automatically) and the operator can easily walk home with the help of the headlights. After 30 seconds, the headlights switch off automatically.

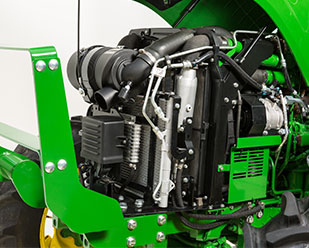

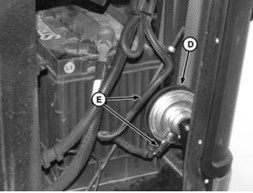

A simplified aftertreatment requires no regen and keeps visibility over the hood

A simplified aftertreatment requires no regen and keeps visibility over the hood

The same powerful, reliable engine you love, but now no regen required on 5E 3-Cylinder models while still meet the U.S. Environmental Protection Agency (EPA) Final Tier 4 (FT4) exhaust emissions regulations. The John Deere PowerTech™ 3029 EWR engine utilizes a diesel oxidation catalyst (DOC) and cooled exhaust gas recirculation (EGR) aftertreatment system – with no DEF fluid, no DPF, and no regen required, you can focus on completing your jobs while your tractor keeps providing the power you need.

- Provide excellent torque and fuel efficiency

- See over the hood with compact aftertreatment design

- Outstanding performance and durability

The engine in this machine is not equipped with a spark arrestor muffler. It is a violation of California Public Resource Code Section 4442 to use or operate this engine on or near any forest-covered, brush-covered or grass-covered land unless the exhaust system is equipped with a spark arrestor meeting any applicable local or state laws. Other states or federal areas may have similar laws. See 'Spark Arrestor Screen' in exhaust attachments section if required for your operating area.

For more information regarding EPA regulations and the technology behind John Deere Integrated Emissions Control systems, please visit the following link: http://www.deere.com/wps/dcom/en_US/campaigns/ag_turf/emissions/final_tier_4.page or https://www.deere.ca/en/engines-and-drivetrain/final-tier-4/

Manure spreader with dual rear SCV

Manure spreader with dual rear SCV

Premium cab with triple mid SCV operating grapple

Premium cab with triple mid SCV operating grapple

Overview

5E 3-Cylinder Series Tractors can be equipped with as many as five (up to two rear and three mid) economical and versatile spool-type SCVs. These SCVs provide a high-flow rate for the tractor's hydraulic system with the open-center hydraulic system.

Benefits

- Additional versatility in configuration for one up to five total SCVs depending on needs with ability to upgrade in the future

- Color coordinated controls located on the right side provide a user-friendly and ergonomic operator experience

- Upgradable, stackable mid SCVs give producers a cost-effective way to add a true third function to your tractor

- Operators not using the tractor for loader work can select a less mid SCV option

Additional details

|

|

Open Operator Station (OOS) |

Standard Cab |

Premium Cab |

Rear SCV |

Single |

Base |

Base |

--- |

Two |

Field-Install Only |

Field-Install Only |

Base |

|

Mid SCV |

Less |

Base |

Base |

--- |

Dual |

Option |

Option |

Base |

|

Triple |

Option |

Option |

Option |

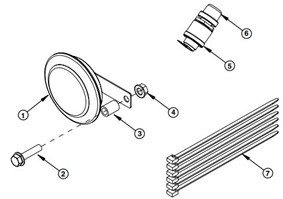

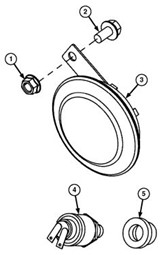

Rear SCVs

Single rear SCVt

Single rear SCVt

Dual rear SCV

Dual rear SCV

The valves are a stackable design and controlled by color-coded levers at the operator's right hand. The single SCV features a detented float position, while the two rear SCV’s first valve features a detented float position and the second valve has a regenerative position.

Mid-mount SCVs

Dual mid-mount SCVs on OOS tractors

Dual mid-mount SCVs on OOS tractors

Triple Mid-SCV with 520M loader lines installed

Triple Mid-SCV with 520M loader lines installed

Mid-mount SCVs are the recommended option for loader operation and feature a detented float position on the first valve and a regenerative position on the second valve for faster loader bucket dump cycles.

Add more versatility to loader with a third function allowing use of grapple, 4-in-1 bucket, or other loader implements requiring additional hydraulic function. Factory-installed triple mid-SCV available starting with model year 2023 provides true third function over previously available field-installed diverter kit (2+1 function). Also starting with model year 2023 the dual mid-SCV has a stackable design to allow for future upgrade to a triple mid-SCV if third loader function is required.

Each valve features extend, retract, neutral, and float positions and is controlled by a unique joystick-control lever mounted on the operator's right-hand side.

Mid-SCV joystick-control lever

Joystick-control mid-mount SCVs on OOS tractorst

Joystick-control mid-mount SCVs on OOS tractorst

Third function button on joystick control

Third function button on joystick control

Tractors that are equipped with dual or triple mid-mount SCVs are controlled by a user-friendly and ergonomic joystick, operating independently of the rear SCVs.

- The joystick is designed to mold to the hand for increased comfort which comes standard on factory-installed dual or triple mid hydraulics

- Securely move around the work site with confidence the material will stay in the bucket with the safety lockout feature that guarantees the joystick does not respond when the lock is on

5075E doing loader work

5075E doing loader work

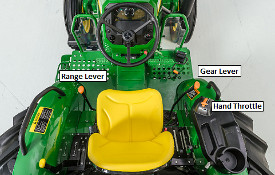

Orange gear and range shift levers

Orange gear and range shift levers

Overview

Ample speeds and ease of operation for demanding applications with the 12F/12R PowrReverser. This transmission comes standard with a dual speed 540/540 economy power take-off (E-PTO) is ideal for applications requiring frequent directional changes such as loader work.

Benefits

- Effortlessly switch directions with a small finger motion using the clutch-less electrohydraulic fingertip directional lever

- Frees the right-hand to operate other tractor controls, such as the loader, rear implements, or throttle, as the directional lever allows the operator to steer and shift direction with the left-hand

- The control is located on the left side of the steering column and selects forward, reverse, and neutral positions

- Ideal for rear blading and any applications that require frequent directional changes in tight spaces

- Lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort from the standard economy PTO (E-PTO)

Additional detail

Electrohydraulic reverser lever

Electrohydraulic reverser lever

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

12F/12R transmission includes:

- Hydraulic wet clutches (forward and reverse)

- Maximize durability and outlast the life of any dry clutch

- When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs

- Platform-mounted shift levers (four gears, three ranges)

- Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience

- The gear-shift lever is easy to reach, and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two

- Left-hand reverser

- Constant-mesh helical-cut gears

- Provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability

- Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating

- Pressure-lubricated top shaft

- Positive park pawl: provides positive park and eliminates the need for a hand brake

- Neutral start switch

The forward lever selects one of four gears. The operator must depress the clutch while shifting. The rear lever selects one of three ranges: A, B, or C.

The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

The speed of directional changes can be adjusted to the operator's preference or application demands with the field-installed infinitely-variable control kit.

See the PTO functional area for more information on E-PTO.

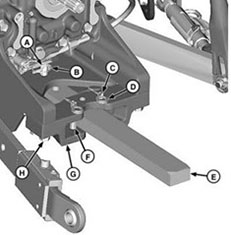

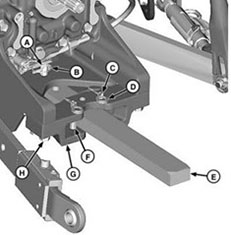

Heavy-duty MFWD front axle on 5E

Heavy-duty MFWD front axle on 5E

MFWD front axle on 5M with turnable fenders

MFWD front axle on 5M with turnable fenders

Overview

Increase drawbar pull and improve traction when operating in slippery conditions with a limited-slip, heavy-duty MFWD front axle provides.

Benefits

- Reduce wheel slippage in demanding conditions getting the required torque to the ground

- Diminish soil compaction with less tractor ballasting compared to two-wheel drive (2WD)

- Increase fuel economy

- Longer tire life

- Excellent maneuverability and high crop clearance

Additional details

MFWD engagement switch on right hand console on 5M

MFWD engagement switch on right hand console on 5M

Steering connections are protected by axle shown on 5E 3-Cylinder

Steering connections are protected by axle shown on 5E 3-Cylinder

Turn around in tight spaces with a turning radius as short as 3.54 m (11.6ft). Operate with consistent performance and enjoy a comfortable ride from the ten degrees of axle oscillation that follows uneven terrain.

Axle oscillation also reduces the stress and maintenance cost on the axle spindles because loads are consistently spread across the entire axle. The centerline design eliminates the need for drive shaft universal joints that require regular maintenance. Anti-wrap shielding on the driveline is standard to prevent crop material and debris from building around the driveline and ensures tractor performance. Minimize maintenance time while maximizing front axle performance with conveniently located three grease points.

NOTE: When MFWD is engaged, an indicator light will appear on the dash. See operator’s manual for additional details on operation and adjustment.

2WD front axle and cab on 45- to 55-kW (60- to 73.7-hp) 5E Tractors

2WD front axle and cab on 45- to 55-kW (60- to 73.7-hp) 5E Tractors

Made of heavy-duty steel for added reliability, the 2WD front axle is adjustable in 50.8-mm (2-in.) increments to adapt to a wide variety of applications.

- The front axle provides 10 degrees of axle oscillation, allowing the axle to follow uneven terrain for a consistent performance, comfortable ride, and reduced stress and maintenance costs on axle spindles.

- A 55-degree turn angle provides excellent maneuverability for high-torque tasks in tight spaces.

- The steering cylinder is bolted directly to the rear of the front axle, so the axle housing protects the steering cylinder from potential punctures created by rough terrain, rocky soil conditions, or thick crop material.

Broadening the 5E 3-Cylinder Tractor product lineup to offer a 2WD front axle in a cab configuration provides you with the well-known benefits of the 5E 3-Cylinder Tractors in conjunction with the ability to stay out of the elements and have the tighter turning radius that 2WD front axles provide.

2WD front axle

2WD front axle

Overview

The SyncShuttle transmission is designed to match the excellent power and torque characteristics of the John Deere PowerTech™ engines. The 9F/3R SyncShuttle provides nine forward and three reverse speeds with in-line synchronized shuttle shifting.

Benefits

- Transmission durability is enhanced with the pressure-lubricated top shaft, allowing the operator to achieve performance from one working season to the next

- Easy and comfortable shifting

- Operator-friendly transmission controls with hand throttle

Additional detail

Additionally, the in-base transmission is configured with fixed draft links, single-speed power take-off (PTO) and mechanical PTO engagement.

The transmission is characterized as full top shaft synchronized (TSS) when forward shifting on-the-go between speeds and is characterized a synchronized while depressing the clutch.

2100 engine rpm |

||

|

|

16.9-28 |

|

Tire |

0.671 RR |

Gear |

Rear Wheel Speed |

Ground Speed |

|

rpm |

km/h |

A1 |

9.1 |

2.3 |

A2 |

12.4 |

3.1 |

A3 |

17.0 |

4.3 |

A Rev |

-13.5 |

-3.4 |

B1 |

23.1 |

5.8 |

B2 |

31.4 |

7.9 |

B3 |

43.2 |

10.9 |

B Rev |

-34.2 |

-8.6 |

C1 |

58.9 |

14.9 |

C2 |

80.3 |

20.3 |

C3 |

110.3 |

27.9 |

C Rev |

-87.3 |

-22.1 |

Creeper available as field installed kit with following speeds in km/h.

| Creeper 1 | 0.40 |

| Creeper 2 | 0.54 |

| Creeper 3 | 0.75 |

| Creeper Rev | -0.59 |

Easy and comfortable shifting

Operator-friendly transmission controls with hand throttle

Operator-friendly transmission controls with hand throttle

Synchronized shifting in all forward and reverse gears

Synchronized shifting in all forward and reverse gears

Range selection pattern

Range selection pattern

Nine forward and three reverse (9F/3R) speeds are achieved by using two platform-mounted levers for shift operation. The gear lever at the operator's right hand selects one of three forward gears and one reverse gear, as well as the integrated park position. The range lever at the operator's left hand selects collar-shift A, B, and C ranges.

Operators can easily switch directions without having to completely stop the tractor with synchronized, in-line, shuttle-shift capability between forward and reverse gears on the gear-shift lever in all three ranges (A, B, and C ranges).

A neutral start switch requires the gear-shift lever be in the neutral or park positions to start the engine.

A positive park pawl on the transmission provides positive park and eliminates the need for a hand brake. This also eliminates clutch service costs that occur when the park brake is accidentally left engaged.

PTO speed selector lever – 5M cab

PTO speed selector lever – 5M cab

Open operator station (OOS) 540E selector lever

Open operator station (OOS) 540E selector lever

Overview

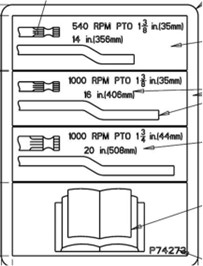

Power an implement at 540 PTO rpm at a lower tractor engine rpm with Economy PTO (540E PTO). Depending on the transmission, the 540E PTO engine requirement could be as low as 1588 rpm. 540E PTO is ideal for many lighter-duty applications including mowing or spraying that do not require full engine horsepower.

Benefits

- Save fuel

- Reduce vibration and noise level

- Increase engine life

Additional details

How does 540E PTO work?

On John Deere Tractors, the shiftable 540/540E mode operates a little like shifting gears on the transmission. By engaging economy mode, the operator changes the gear reduction ratio keeping the PTO spinning at 540 rpm while reducing the engine rpm. When the operator shifts the PTO back into the standard 540 mode, a different gear ratio is used to operate the PTO at 540 rpm and the engine at standard PTO rated speed.

To operate in economy mode, the shiftable 540/540E lever must be in 540E and then the throttle can be increased to the appropriate rpm. When in 540E, the tractor has a throttle limiter that keeps the operator from increasing engine rpm over the 540E setting. The limiter is used to prevent accidental over-speeding of PTO implements and protection against binding the PTO shaft.

The 540E setting cannot be used with full advertised PTO horsepower. If full PTO horsepower is required, operate the tractor in the standard 540 mode.

Details on the engine rpm required for standard 540 and 540 economy mode can be found in the operator’s manual along with additional details on operation and adjustment.

Stationary operation of the rear PTO with operator out of seat

Stationary PTO enable switch (cab)

Stationary PTO enable switch (cab)

Stationary PTO enable switch (OOS)

Stationary PTO enable switch (OOS)

The stationary PTO enable switch is in base for all 5000 Utility Tractors produced starting on 1 November 2020 (except for the 5E 3-Cylinder Tractors with 9F/3R transmission which began in November 2021). The PTO shuts down if the operator leaves the seat with the PTO on. Stationary operation of a tractor PTO-powered implement allows the operator to leave the driving position with the PTO engaged by pressing the stationary PTO enable switch. See operator’s manual for additional details on operation and adjustment. Refer to the chart below for models with the stationary PTO enable switch in base.

Specs & Compare

Key Specs | 5075E Current Model |

| Engine description | John Deere PowerTech™ 3029 EWR |

| Engine displacement | 3 cylinders: 2.9 L 179 cu in. |

| Rated engine power | At 2100 rpm: 55 kW 73.7 hp |

| Maximum engine power | At 2100 rpm: 55 kW 73.7 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: OOS 45 kW (60.3 PTO hp) Cab 43 kW (57.6 PTO hp) |

| Maximum PTO power | At 1800 rpm: OOS 46.3 kW (62 PTO hp) Cab 45.5 kW (61 PTO hp) |

| Transmission type | Standard: SyncShuttle™ 9F/3R Optional: PowrReverser™ 12F/12R |

| Hydraulic pump rated output | Standard: 68.8 L/min 18.2 gpm |

| Rear hitch category (SAE designation) | Category 2; convertible to 1 |

| Base machine weight | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Engine specifications | |

| Description | John Deere PowerTech™ 3029 EWR |

| Engine type | 3029HPY110 |

| Engine family | NJDXL02.9339 |

| Rated speed | 2100 rpm |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | DOC/EGR |

| Displacement | 3 cylinders: 2.9 L 179 cu in. |

Engine performance | |

| Rated power | At 2100 rpm: 55 kW 73.7 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: OOS 45 kW (60.3 PTO hp) Cab 43 kW (57.6 PTO hp) |

| Maximum PTO power | At 1800 rpm: OOS 46.3 kW (62 PTO hp) Cab 45.5 kW (61 PTO hp) |

| Intelligent Power Management (IPM) | |

| Power boost | 0 percent |

| Maximum engine power | At 2100 rpm: 55 kW 73.7 hp |

| Engine peak torque | At 1500 rpm: 304 Nm 224 lb-ft |

| Drawbar power | |

| PTO torque rise | 21 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Transmission | |

| Type | Standard: SyncShuttle™ 9F/3R Optional: PowrReverser™ 12F/12R |

| Reverser | SyncShuttle™: No PowrReverser™: Yes |

| Clutch; wet/dry | SyncShuttle™: Dry PowrReverser™: Wet |

| Creeper | Kit available for OOS SyncShuttle™ 9F/3R transmission |

Hydraulic system | |

| Type | Open center |

| Pump rated output | Standard: 68.8 L/min 18.2 gpm |

| Available flow at a single rear SCV | 43.1 L/min 11.4 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Standard: One Optional: Two |

| Number of mid selective control valves (SCVs) | Standard: Zero Optional: Up to Three |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | Optional |

| Auxiliary hydraulic features | |

| SCV control | Mechanical |

Rear hitch | |

| Hitch draft control load sense type | Mechanical |

| Remote control valves available | Standard: One Optional: Two |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | 1448 kg 3192 lb |

| Lift capacity at standard frame | |

| Sensing type | Top link |

| Rear axle differential lock | |

Drawbar | |

| Drawbar category | |

| Maximum vertical load | Road/field use (short position): 1120 kg 2470 lb Field use (fully extended): 760 kg 1675 lb |

Rear power take-off (PTO) | |

| Type | SyncShuttle™: Independent 540 PowrReverser™: Independent 540/540E |

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1588 rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | SyncShuttle™: Mechanical (lever) PowrReverser™: Electrohydraulic |

Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

Rear axle | |

| Type | Flange |

| Final drive type | Planetary |

| Differential controls | Mechanical (pedal) |

| Axle type | |

| Brakes, type and control | Hydraulic wet disc |

| Rear differential lock | |

| Load rating | |

Front axle | |

| Type | |

| Front axle differential lock | |

| Load rating | |

Tires | |

| Rear | 2WD: 16.9-28 R1 Bias MFWD: 16.9-28 R1 Bias |

| Wheel tread range | |

| Turning radius with brakes | 2WD: 3.1 m 10.2 ft MFWD: 3.94 m 12.9 ft |

| Turning radius without brakes | 2WD: 3.5 m 11.5 ft MFWD: 4.65 m 15.3 ft |

| Central Tire Inflation System (CTIS) | |

| Front | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | OOS: 70 amp Cab: 110 amp |

| Battery options | 12 V |

| Working lights | Standard: Halogen Premium Cab: LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | OOS: Halogen Cab: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | Kit: Halogen |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | |

Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, two-post Platform - flat/straddle Straddle Gearshift location - console/floor Floor, on the side |

| Seat | Standard: Mechanical Premium Cab: Air Ride |

| Cab suspension | |

| Instructional seat | Optional |

| Display | Simple automotive-style instrument cluster |

| Radio | Optional |

| Inner cab volume | |

| dB(A) rating | 81 dBA |

| Cab glass area | |

| Safety glass rating | |

| Front visibility | |

Dimensions | |

| Wheelbase | 2WD and MFWD: 2050 mm 80.7 in. |

| Overall width | |

| Overall length | 3639 mm 143.3 in. |

| Overall height | |

| Drawbar clearance | |

| Front axle center | |

| Approximate shipping weight, Open;Cab | 2WD OOS: 2520 kg 5555 lb 2WD Cab 2989 kg 6590 lb MFWD OOS: 2735 kg 6029 lb MFWD Cab: 3090 kg 6812 lb |

Weight | |

| Base machine weight | |

| Maximum ballast level | |

| Maximum permissible weight | |

Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard: Open: 72.5 L 19 U.S. gal. Cab: 82 L 21 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | Not Applicable |

| Cooling system | |

| Transmission-hydraulic system | |

Serviceability | |

| Interval for engine oil change | |

| Interval for hydraulic/transmission oil change | |

| Interval for engine coolant change | |

Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Leveling type | |

Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

Miscellaneous | |

| AutoTrac ready | No |

| ISOBUS ready | No |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | Sub assembly in Pune, India, Final assembly in Augusta, GA |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

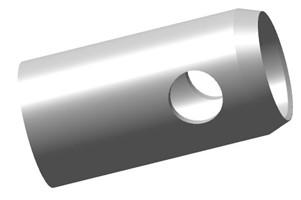

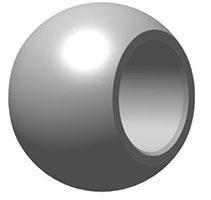

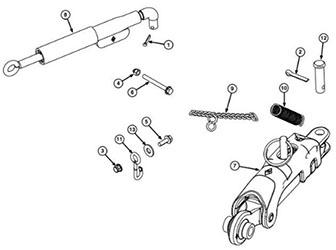

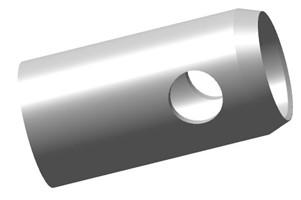

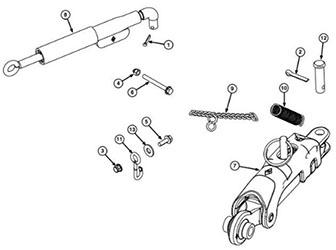

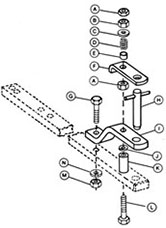

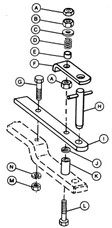

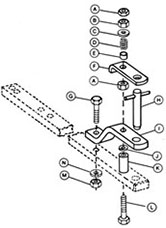

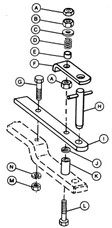

Draft Link

Implement hitch pins and bushings adapt Category 1 implements to fit a Category 2 3-point hitch.

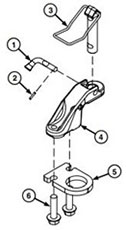

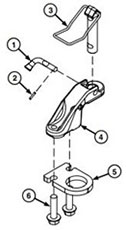

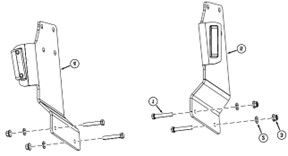

R66432 Draft link conversion bushing shown

R66432 Draft link conversion bushing shown

T21706 Hitch ball shown

T21706 Hitch ball shown

SJ11072-SJ11073 Telescoping draft link shown

SJ11072-SJ11073 Telescoping draft link shown

BLV10487 Automatic stabilizer kit shown

BLV10487 Automatic stabilizer kit shown

Overview

Telescoping draft links will reduce the amount of effort to attach 3-point hitch implements by allowing the operator to make small adjustments without moving the tractor.

R66432 Draft link conversion bushing shown

R66432 Draft link conversion bushing shown

T21706 Hitch ball shown

T21706 Hitch ball shown

SJ11072-SJ11073 Telescoping draft link shown

SJ11072-SJ11073 Telescoping draft link shown

BLV10487 Automatic stabilizer kit shown

BLV10487 Automatic stabilizer kit shown

Overview

Telescoping draft links will reduce the amount of effort to attach 3-point hitch implements by allowing the operator to make small adjustments without moving the tractor.

Drawbar

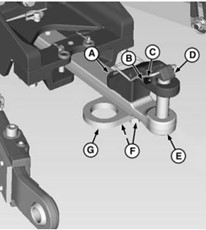

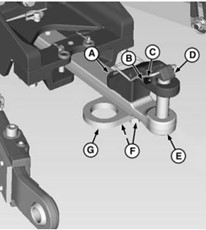

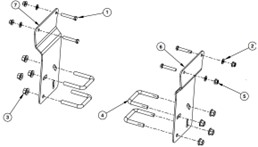

RE242110 Hammer Strap and Chain Clevis Kit shown

RE242110 Hammer Strap and Chain Clevis Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

BSJ10503 Air Trailer Brake Kit shown

BSJ10503 Air Trailer Brake Kit shown

RE39829 Drawbar Clevis Kit shown

RE39829 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

R196191 Drawbar shown

R196191 Drawbar shown

R133359 Drawbar shown

R133359 Drawbar shown

R197239 Drawbar shown

R197239 Drawbar shown

Overview

Drawbars, Hammer strap and chain clevis kits allow for operators to change the positioning of the drawbar based on operation being completed.

NOTE: Refer to owner’s manual for drawbar and PTO specifications

Offset drawbar

Offset drawbar

Offset drawbars can be used with large- or small-diameter tires to raise or lower the drawbar height.

RE242110 Hammer Strap and Chain Clevis Kit shown

RE242110 Hammer Strap and Chain Clevis Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

BSJ10503 Air Trailer Brake Kit shown

BSJ10503 Air Trailer Brake Kit shown

RE39829 Drawbar Clevis Kit shown

RE39829 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

R196191 Drawbar shown

R196191 Drawbar shown

R133359 Drawbar shown

R133359 Drawbar shown

R197239 Drawbar shown

R197239 Drawbar shown

Overview

Drawbars, Hammer strap and chain clevis kits allow for operators to change the positioning of the drawbar based on operation being completed.

NOTE: Refer to owner’s manual for drawbar and PTO specifications

Straight drawbar clevis kit

Straight drawbar clevis kit

The offset drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Straight drawbar clevis kit

Straight drawbar clevis kit

The straight drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Open Operator's Station

Standard canopy mounted to 5M Series ROPS

Standard canopy mounted to 5M Series ROPS

The standard canopy attaches to the tractor's rollover protective structure (ROPS) to protect operators from inclement weather.

Additional mounting brackets and hardware bundles are required to install the canopy to the ROPS.

LVB25334 Canopy Kit shown

LVB25334 Canopy Kit shown

LVB25332 Canopy Mounting Kit shown

LVB25332 Canopy Mounting Kit shown

BSJ10363 Canopy Mounting Kit shown

BSJ10363 Canopy Mounting Kit shown

BSJ10341 Canopy Mounting Kit shown

BSJ10341 Canopy Mounting Kit shown

Overview

The canopy attaches to the tractor’s rollover protective structure (ROPS) to protect operators from the sun and inclement weather.

RE193737 Horn Kit shown

RE193737 Horn Kit shown

SJ288924 Horn Kit shown

SJ288924 Horn Kit shown

SJ12143 Horn Kit shown

SJ12143 Horn Kit shown

Overview

The electric horn serves as a warning or signal device from the operator.

Operator's Station

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

RAM is a trademark of National Products Inc.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

RAM is a trademark of National Products Inc.

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

- Self-leveling action reduces spills

- Durable design for rough environments

- Easy adjustable mounting for ideal placement

- Includes John Deere branded beverage insulator

- Compatible with most monitor brackets and all 10-mm threaded bosses

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

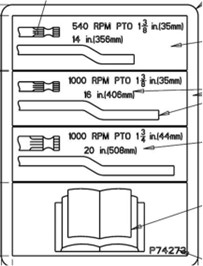

Power Take-Off (PTO)

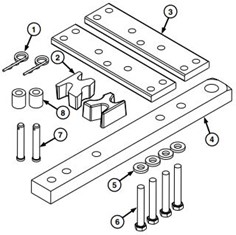

Wheel Tread Width

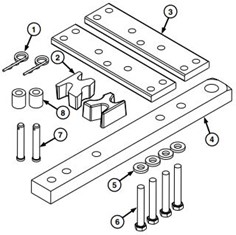

Axle extensions are required to achieve wider tread settings.

Axle extensions are required to achieve wider axle tread settings.

Axle extensions are required to achieve wider axle tread settings.

Reviews

Location: East TN

Length of Ownership: 6months

Usage: Weekly

Bought this tractor in late 2017- have had problems every year since. Machine seems to be afraid of a hay field as it has a problem every year when hay season starts. When all is working it’s a handy and comfortable tractor but the failures are not worth the hassle- especially on a machine with only 200 hours on it. Look elsewhere.

Location: Colorado

Length of Ownership: 3months

Usage: Weekly

Me my dad bought this 5075e for just using on our 27 acre farm. We have 38hp John Deere 1070 thats about 20 years old now. Overall this tractor is great, We haven't put much hours on this unit. We also have the 520m loader which the hose assembly was ok however we had to make some adjustment where the hose mounting brackets where hitting the tire whenever it turn right. That wasn't really a big issue but other than that this tractor has telescoping end link on the lower 2 control arms and make hooking up implement way easier. Plus the 12/12 is very good use for loader work.

Location: Fort Kent Maine

Length of Ownership: 1month

Usage: Daily

I traded my open cab 4300 tractor of 20 years for a 5075e cab tractor with a 240 loader. Tired of dressing to ride snowmobile to blow snow. It’s much more of a tractor I’m used to, 12/12 transmission, cab, turbo to name a few. Find it’s warm blooded, foot throttle is hard to press, reverse is faster than foward speed in same gear, but over all it’s awesome. I have a 97” blower coming and there is no doubt in my mind it will handle the job.

Location: NEbraskA

Length of Ownership: 1yearOrLonger

Usage: Monthly

My 2016 5075 with only 60 hours has leaked universal transmission fluid sine the day I bought it. It’s an isolated leak difficult to locate. A JD mechanic looked at it a year ago when the local dealer brokered it to me the local dealer brokered it to me a year ago with 22 hours. He found one leak, could not locate the other. So I have a relatively new JD which I keep adding transmission fluid and meanwhile i leave cardboard under it to rote the my shop floor. Aggravating. 5 stars all the way if not for this on going issue.

Location: North Carolina

Length of Ownership: 1yearOrLonger

Usage: Daily

I bought a 5075E Cab tractor with an H240 loader in March of 2017. I went with the 12/12 transmission. It's been a great tractor. Very little issues. I use the tractor daily on my livestock operation and we have logged over 1000 hours doing numerous chores. Loader work, hay chores, bush hogging, etc. I wish the tractor had more fuel capacity so I could run longer in the hay field without stopping. Tractor is a little weak in the top end but all in all well worth the money.

Location: Leesburg, Ga

Length of Ownership: 1yearOrLonger

Usage: Daily

Purchased a new 5075E OOS and loader with 4 way Frontier bucket in early 2019. In 2018, I purchased a new 5100M with premium cab and loader. While I love them both, I have already logged more hours on the 5075. I've used it on the farm for everything from tree and brush removal to mowing for about a year now and have had zero issues. Plenty of power, and easy to maneuver in tight places. If you add the loader, be sure to choose the power reverser transmission. If you are in the market for a tough, reliable tractor, this is the one!

Pros:

- ease of operation

- plenty of power

- dependable

Cons:

- have not found one!

Location: Alabama

Length of Ownership: 1yearOrLonger

Usage: Weekly

Tractor got plenty room in cab. Air/heat works great, radio is fairly good as well. The only negative thing I can say is the tractor is kinda weak to be a 75 horse power tractor. I have a 5303 and it feels like it has more torque/power.

Pros:

- roomy cab

- mulitple hydraulic ports

- quick connect loader

- no def fluid

Cons:

- small fuel tank

- weak for a 75hp tractor

Location: Alabama

Length of Ownership: 3months

Usage: Weekly

The tractor is very nice, however, the foot throttle is not user friendly. My biggest complaint would be the fuel efficiency, or lack there of. I've tried 540e and 540 and both are terrible on fuel. Other than that, this tractor is great! A real work horse for hay farming and bush hogging, as well as plowing and planting.

Pros:

- work horse

Cons:

- terrible fuel efficiency

Location: Texas

Length of Ownership: 6months

Usage: Daily

I have had my cab 5075e for 3 months. I have pulled my 12ft batwing over head high grass and the tractor acts like there is no grass there. Pulling a 6ft is a joke to this tractor. The cab is quite the radio is great. Overall a tractor that i love as much as my wife ( dont tell her that). You wont regret your purchase if you buy this tractor, good on fuel also.

Pros:

- awesome with any implement

- awesome front end loader capacity

Cons:

- if you can find one let me know

- there are none

Location: Decatur TX

Length of Ownership: 3months

Usage: Weekly

Traded in a 4320 open station 2008 model on a 2019 5075E cab tractor with loader. Got my tractor from united in Rhome TX. Excellent customer service. Very fast getting the unit ready to go. I needed a larger tractor to haul over to our other farm, made the decision while flying back from seattle to DFW. had wifi on the plane, did the entire deal while flying including the trade in. Had papers waiting when I drove by the Rhome United ag store and signed and picked up the tractor the next morning and headed out. Put 20 hours clearing brush and mowing that weekend and everything worked flawlessly and AC is very good, was over 100 out. It does like fuel when pushing it, tank could be a bit bigger but overall its a great value. I have watched the reviews for a while and while early units did have some teething issues. i think John Deere has listened and its a good value product. Im happy with it.

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By