5050E

Utility Tractor

- 2WD or MFWD

- 5-year Powertrain warranty*

- Available in open operator station

- No Regen required

View Product Brochure

Features

Adding ease to operation

Enhanced operator controls

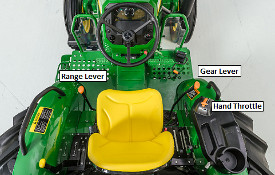

Enhanced operator controls

Operator comfort is important regardless of the application. Improving the 5E 3-Cylinder Tractor models, the hand throttle has been relocated to the right-hand console. This is 30.5 cm (12-in.) closer to the operator and within easy reach versus the previous location on the center-hand console. Operators may also notice the additional legroom provided by the repositioned loader controls, providing a more enjoyable experience.

Overview

The SyncShuttle transmission is designed to match the excellent power and torque characteristics of the John Deere PowerTech™ engines. The 9F/3R SyncShuttle provides nine forward and three reverse speeds with in-line synchronized shuttle shifting.

Benefits

- Transmission durability is enhanced with the pressure-lubricated top shaft, allowing the operator to achieve performance from one working season to the next

- Easy and comfortable shifting

- Operator-friendly transmission controls with hand throttle

Additional detail

Additionally, the in-base transmission is configured with fixed draft links, single-speed power take-off (PTO) and mechanical PTO engagement.

The transmission is characterized as full top shaft synchronized (TSS) when forward shifting on-the-go between speeds and is characterized a synchronized while depressing the clutch.

2100 engine rpm |

||

|

|

16.9-28 |

|

Tire |

0.671 RR |

Gear |

Rear Wheel Speed |

Ground Speed |

|

rpm |

km/h |

A1 |

9.1 |

2.3 |

A2 |

12.4 |

3.1 |

A3 |

17.0 |

4.3 |

A Rev |

-13.5 |

-3.4 |

B1 |

23.1 |

5.8 |

B2 |

31.4 |

7.9 |

B3 |

43.2 |

10.9 |

B Rev |

-34.2 |

-8.6 |

C1 |

58.9 |

14.9 |

C2 |

80.3 |

20.3 |

C3 |

110.3 |

27.9 |

C Rev |

-87.3 |

-22.1 |

Creeper available as field installed kit with following speeds in km/h.

| Creeper 1 | 0.40 |

| Creeper 2 | 0.54 |

| Creeper 3 | 0.75 |

| Creeper Rev | -0.59 |

Easy and comfortable shifting

Operator-friendly transmission controls with hand throttle

Operator-friendly transmission controls with hand throttle

Synchronized shifting in all forward and reverse gears

Synchronized shifting in all forward and reverse gears

Range selection pattern

Range selection pattern

Nine forward and three reverse (9F/3R) speeds are achieved by using two platform-mounted levers for shift operation. The gear lever at the operator's right hand selects one of three forward gears and one reverse gear, as well as the integrated park position. The range lever at the operator's left hand selects collar-shift A, B, and C ranges.

Operators can easily switch directions without having to completely stop the tractor with synchronized, in-line, shuttle-shift capability between forward and reverse gears on the gear-shift lever in all three ranges (A, B, and C ranges).

A neutral start switch requires the gear-shift lever be in the neutral or park positions to start the engine.

A positive park pawl on the transmission provides positive park and eliminates the need for a hand brake. This also eliminates clutch service costs that occur when the park brake is accidentally left engaged.

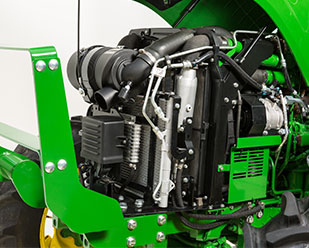

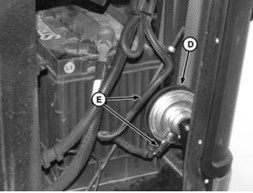

A simplified aftertreatment requires no regen and keeps visibility over the hood

A simplified aftertreatment requires no regen and keeps visibility over the hood

The same powerful, reliable engine you love, but now no regen required on 5E 3-Cylinder models while still meet the U.S. Environmental Protection Agency (EPA) Final Tier 4 (FT4) exhaust emissions regulations. The John Deere PowerTech™ 3029 EWR engine utilizes a diesel oxidation catalyst (DOC) and cooled exhaust gas recirculation (EGR) aftertreatment system – with no DEF fluid, no DPF, and no regen required, you can focus on completing your jobs while your tractor keeps providing the power you need.

- Provide excellent torque and fuel efficiency

- See over the hood with compact aftertreatment design

- Outstanding performance and durability

The engine in this machine is not equipped with a spark arrestor muffler. It is a violation of California Public Resource Code Section 4442 to use or operate this engine on or near any forest-covered, brush-covered or grass-covered land unless the exhaust system is equipped with a spark arrestor meeting any applicable local or state laws. Other states or federal areas may have similar laws. See 'Spark Arrestor Screen' in exhaust attachments section if required for your operating area.

For more information regarding EPA regulations and the technology behind John Deere Integrated Emissions Control systems, please visit the following link: http://www.deere.com/wps/dcom/en_US/campaigns/ag_turf/emissions/final_tier_4.page or https://www.deere.ca/en/engines-and-drivetrain/final-tier-4/

Specs & Compare

Key Specs | 5050E Current Model |

| Engine description | John Deere PowerTech™ 3029 EWR |

| Engine displacement | 3 cylinders: 2.9 L 179 cu in. |

| Rated engine power | At 2100 rpm: 37.4 kW 50 hp |

| Maximum engine power | At 2100 rpm: 37.4 kW 50 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: 27.6 kW (37 PTO hp) |

| Maximum PTO power | At 1800 rpm: OOS: 28.5 kW (38 PTO hp) |

| Transmission type | Standard: SyncShuttle™ 9F/3R |

| Hydraulic pump rated output | Standard: 68.8 L/min 18.2 gpm |

| Rear hitch category (SAE designation) | Category 2; convertible to 1 |

| Base machine weight | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Engine specifications | |

| Description | John Deere PowerTech™ 3029 EWR |

| Engine type | 3029HPY110 |

| Engine family | NJDXL02.9339 |

| Rated speed | 2100 rpm |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | DOC/EGR |

| Displacement | 3 cylinders: 2.9 L 179 cu in. |

Engine performance | |

| Rated power | At 2100 rpm: 37.4 kW 50 hp |

| Rated PTO power (hp SAE) | At 2100 rpm: 27.6 kW (37 PTO hp) |

| Maximum PTO power | @ 1800 RPM Open Station: 28.5 kW (38 PTO hp) |

| Intelligent Power Management (IPM) | |

| Power boost | 0 percent |

| Maximum engine power | At 2100 rpm: 37.4 kW 50 hp |

| Engine peak torque | At 1500 rpm: 209 Nm 154 lb-ft |

| Drawbar power | |

| PTO torque rise | 22 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Transmission | |

| Type | Standard: SyncShuttle™ 9F/3R |

| Reverser | No |

| Clutch; wet/dry | Dry |

| Creeper | Kit available for OOS SyncShuttle™ 9F/3R transmission |

Hydraulic system | |

| Type | Open Center |

| Pump rated output | Standard: 68.8 L/min 18.2 gpm |

| Available flow at a single rear SCV | 43.1 L/min 11.4 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Standard: One Optional: Two |

| Number of mid selective control valves (SCVs) | Standard: Zero Optional: Up to Three |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | Optional |

| Auxiliary hydraulic features | |

| SCV control | Mechanical |

Rear hitch | |

| Hitch draft control load sense type | Mechanical |

| Remote control valves available | Standard: One Optional: Two |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | 1448 kg 3192 lb |

| Lift capacity at standard frame | |

| Sensing type | Top link |

| Rear axle differential lock | |

Drawbar | |

| Drawbar category | |

| Maximum vertical load | Road/field use (short position): 1120 kg 2470 lb Field use (fully extended): 760 kg 1675 lb |

Rear power take-off (PTO) | |

| Type | Independent 540 |

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Mechanical (lever) |

Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

Rear axle | |

| Type | Flange |

| Final drive type | Planetary |

| Differential controls | Mechanical (pedal) |

| Axle type | |

| Brakes, type and control | Hydraulic wet disc |

| Rear differential lock | |

| Load rating | |

Front axle | |

| Type | |

| Front axle differential lock | |

| Load rating | |

Tires | |

| Rear | 2WD: 14.9-28 R1 Bias MFWD: 14.9-28 R1 Bias |

| Wheel tread range | |

| Turning radius with brakes | 2WD: 3.1 m 10.2 ft MFWD: 3.94 m 12.9 ft |

| Turning radius without brakes | 2WD: 3.5 m 11.5 ft MFWD: 4.65 m 15.3 ft |

| Central Tire Inflation System (CTIS) | |

| Front | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | 70 amp |

| Battery options | 12 V |

| Working lights | Halogen |

| Type of bulb in headlight (Halogen, Zenon, LED) | Halogen |

| Type of bulb in beacon (Halogen, Zenon, LED) | Kit: Halogen |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | |

Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Straddle Gearshift location - console/floor Floor, on the side |

| Seat | Mechanical |

| Cab suspension | |

| Instructional seat | |

| Display | Simple automotive-style instrument cluster |

| Radio | |

| Inner cab volume | |

| dB(A) rating | |

| Cab glass area | |

| Safety glass rating | |

| Front visibility | |

Dimensions | |

| Wheelbase | 2WD and MFWD: 2050 mm 80.7 in. |

| Overall width | |

| Overall length | 3639 mm 143.3 in. |

| Overall height | |

| Drawbar clearance | |

| Front axle center | |

| Approximate shipping weight, Open;Cab | 2WD OOS: 2420 kg 5335 lb MFWD OOS: 2634 kg 5809 lb |

Weight | |

| Base machine weight | |

| Maximum ballast level | |

| Maximum permissible weight | |

Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard: 72.5 L 19 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | Not Applicable |

| Cooling system | |

| Transmission-hydraulic system | |

Serviceability | |

| Interval for engine oil change | |

| Interval for hydraulic/transmission oil change | |

| Interval for engine coolant change | |

Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Leveling type | |

Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

Miscellaneous | |

| AutoTrac ready | No |

| ISOBUS ready | No |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | Sub assembly in Pune, India, Final assembly in Augusta, GA |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

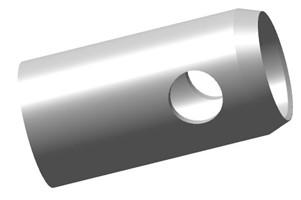

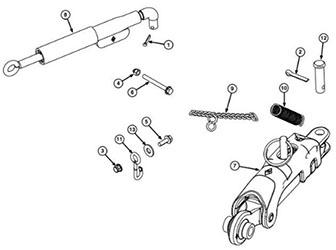

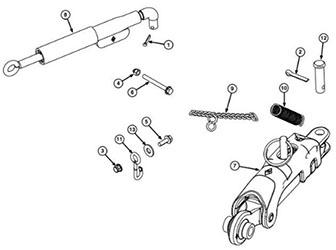

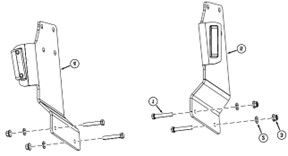

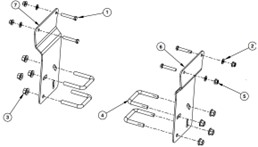

Draft Link

Implement hitch pins and bushings adapt Category 1 implements to fit a Category 2 3-point hitch.

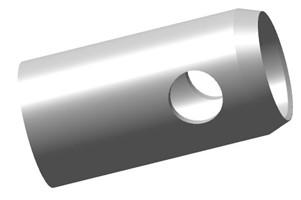

R66432 Draft link conversion bushing shown

R66432 Draft link conversion bushing shown

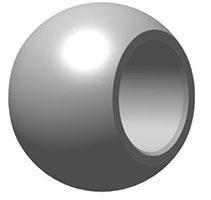

T21706 Hitch ball shown

T21706 Hitch ball shown

SJ11072-SJ11073 Telescoping draft link shown

SJ11072-SJ11073 Telescoping draft link shown

BLV10487 Automatic stabilizer kit shown

BLV10487 Automatic stabilizer kit shown

Overview

Telescoping draft links will reduce the amount of effort to attach 3-point hitch implements by allowing the operator to make small adjustments without moving the tractor.

R66432 Draft link conversion bushing shown

R66432 Draft link conversion bushing shown

T21706 Hitch ball shown

T21706 Hitch ball shown

SJ11072-SJ11073 Telescoping draft link shown

SJ11072-SJ11073 Telescoping draft link shown

BLV10487 Automatic stabilizer kit shown

BLV10487 Automatic stabilizer kit shown

Overview

Telescoping draft links will reduce the amount of effort to attach 3-point hitch implements by allowing the operator to make small adjustments without moving the tractor.

Drawbar

Offset drawbar

Offset drawbar

Offset drawbars can be used with large- or small-diameter tires to raise or lower the drawbar height.

Straight drawbar clevis kit

Straight drawbar clevis kit

The offset drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Straight drawbar clevis kit

Straight drawbar clevis kit

The straight drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Open Operator's Station

Standard canopy

Standard canopy

Deluxe canopy

Deluxe canopy

The canopy attaches to the open operator station rollover protective structure (ROPS).

The 1613.2-mm (63.5-in.) long, 1322.7-mm (52-in.) wide ABS canopy can offer protection to the operator from inclement weather and direct overhead sunlight.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

LVB25334 Canopy Kit shown

LVB25334 Canopy Kit shown

LVB25332 Canopy Mounting Kit shown

LVB25332 Canopy Mounting Kit shown

BSJ10363 Canopy Mounting Kit shown

BSJ10363 Canopy Mounting Kit shown

BSJ10341 Canopy Mounting Kit shown

BSJ10341 Canopy Mounting Kit shown

Overview

The canopy attaches to the tractor’s rollover protective structure (ROPS) to protect operators from the sun and inclement weather.

RE193737 Horn Kit shown

RE193737 Horn Kit shown

SJ288924 Horn Kit shown

SJ288924 Horn Kit shown

SJ12143 Horn Kit shown

SJ12143 Horn Kit shown

Overview

The electric horn serves as a warning or signal device from the operator.

Operator's Station

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

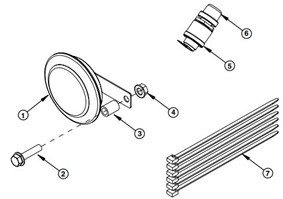

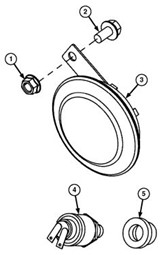

Power Take-Off (PTO)

Wheel Tread Width

Axle extensions are required to achieve wider tread settings.

Axle extensions are required to achieve wider axle tread settings.

Axle extensions are required to achieve wider axle tread settings.

Reviews

Location: Spirit Lake, Idaho

Length of Ownership: 1yearOrLonger

Usage: Weekly

I purchased the 5045E in August 2018 for off-grid living and it has been a joy to own and use around our 20 acres in the Panhandle Idaho area.

Location: Heyworth, il

Length of Ownership: 1yearOrLonger

Usage: Weekly

I have a little over 100 hours on my 5045e. For my 10 acre farm, this tractor as I had hoped, offers functionality, simplicity and utility in mowing, tilling, and with the loader, many other tasks around the property including, snow removal, dirt/gravel moving. I looked at many other models, and this one meets my needs without hydrostatic transmissions... this tractor really combines comfort, ease of use and serviceability in a very affordable package.

Pros:

- visibility

- economical

Cons:

- perminant loader attachment

Location: telangana,manuguru

Length of Ownership: 1yearOrLonger

Usage: Daily

it has lot of specifications,and best technical product it is very comfortable for the drivers

Pros:

- technology

Cons:

- over heat

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By