5090EL

Low-Profile Utility Tractor

- Low clearance design allows for overall height of 69 inches

- 90 hp John Deere PowerTech™ engine

- Economy PTO allows engine RPM to run lower, saving fuel and reducing overall cost of operation

- 2-year or 2,000-hour full comprehensive warranty and 5-year or 2,000-hour Powertrain warranty

View Product Brochure

Features

5090EL Tractor

5090EL Tractor

Leveraging the proven 5E 4-cylinder platform, the 5090EL Tractor is suited to fit in confined spaces where clearance is a constraint. While this model is of special interest to poultry farmers, it has the power to tackle other jobs with various implements.

Special adjustments were made to accommodate low clearance applications. By lowering the rollover protective structure (ROPS) hinge point, operators will be able to reduce the overall tractor height, enabling them to stay below overhead obstacles. Adding to the possibility for low clearance, a factory-installed side exhaust is offered with the 5090EL Tractor. Lastly, updated tire options are available to suit the application. Regardless of tire selection, fenders can be adjusted to accommodate producer preference while optional additional fenders can be added to provide ample coverage to protect operators from mud and debris.

Power bulge and torque curve

Power bulge and torque curve

Overview

When the tractor is under load, power bulge and torque rise work together to get through the tough spots without having to downshift.

As rpm drops, the only way to maintain or increase horsepower is to provide additional torque. Whether bailing wet hay or lifting a heavy load, the additional power allows the tractor to continue performing the job without stopping. The rated economy power take-off (EPTO) speed occurs near the peak torque rise providing power when operator need it in PTO applications.

Benefits

- Increased productivity in demanding conditions with more power when operator need it

- More lugging ability for quicker power recovery

- Additional torque provides force to remain horsepower as engine rpm drops below rated speed

Additional Details

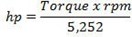

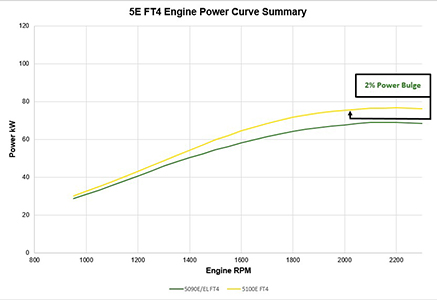

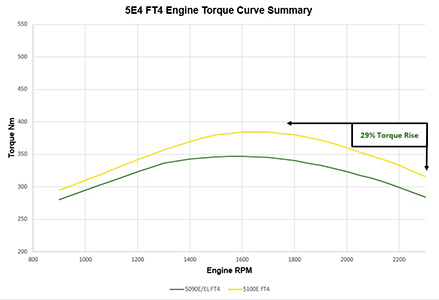

Horsepower and torque are mathematically related.

5M 4-Cylinder tractors provide 4% power bulge while 5E 4-Cylinder tractors provide 2% power bulge. Note: There is no power bulge on 3-Cylinder tractors (5E 3-Cylinder or 5075M).

5E 4-Cylinder Power and Torque Curves

5E power curve summary

5E power curve summary

5E torque curve summary

5E torque curve summary

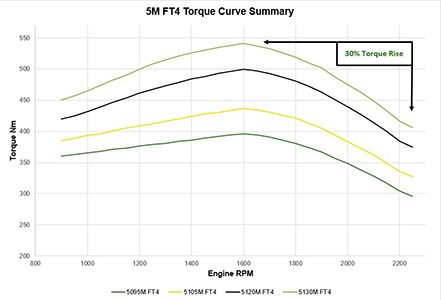

5M Power and Torque Curves

5M power curve summary

5M power curve summary

5M torque curve summary

5M torque curve summary

Gear shift lever with hi-lo buttons

Gear shift lever with hi-lo buttons

Overview

Ample speeds and ease of operation for demanding applications with the 24F/12R PowrReverser, providing 24 forward speeds and 12 reverse speeds. This transmission comes standard with a dual speed 540/540 Economy power take-off (PTO), and it is ideal for applications requiring frequent directional changes, such as loader work and PTO work like rotary cutting and baling hay.

Benefits

- Effortlessly switch directions with a small finger motion using the electrohydraulic fingertip directional lever

- Frees the right-hand to operate other tractor controls, such as the loader, rear implements, or throttle, as the directional lever allows the operator to steer and shift direction with the left-hand

- The control is located on the left side of the instrument console and selects forward, reverse, and neutral positions

- Ideal for rear blading and any applications that require frequent directional changes in tight spaces

- Clutch-less hydraulic shifting between forward and reverse

- Lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort from the standard economy PTO (E-PTO)

Additional details

The hi/lo selector buttons are located on the gear shift lever for each forward gear and are represented by a rabbit and a turtle, respectively.

The forward lever selects one of four gears. All are synchronized for on-the-go shifting with the use of the clutch. The rear lever selects one of three ranges: A, B, or C.

24F/12R transmission includes:

- Hydraulic wet clutches (forward and reverse)

- Maximize durability and outlast the life of any dry clutch

- When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs

- Platform-mounted shift levers (four gears, three ranges)

- Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience

- The gearshift lever is easy to reach, and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two

- Left-hand reverser

- Constant-mesh helical-cut gears

- Provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability

- Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating

- Pressure-lubricated top shaft

- Positive park pawl

- Neutral start switch

The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

A neutral start switch requires the directional lever be in the neutral position to start the engine.

The speed of directional changes can be adjusted to the operator's preference or application demands with an optional field installed infinitely variable control kit.

See the PTO functional area for more information on E-PTO.

5075E doing loader work

5075E doing loader work

Orange gear and range shift levers

Orange gear and range shift levers

Overview

Ample speeds and ease of operation for demanding applications with the 12F/12R PowrReverser. This transmission comes standard with a dual speed 540/540 economy power take-off (E-PTO) is ideal for applications requiring frequent directional changes such as loader work.

Benefits

- Effortlessly switch directions with a small finger motion using the clutch-less electrohydraulic fingertip directional lever

- Frees the right-hand to operate other tractor controls, such as the loader, rear implements, or throttle, as the directional lever allows the operator to steer and shift direction with the left-hand

- The control is located on the left side of the steering column and selects forward, reverse, and neutral positions

- Ideal for rear blading and any applications that require frequent directional changes in tight spaces

- Lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort from the standard economy PTO (E-PTO)

Additional detail

Electrohydraulic reverser lever

Electrohydraulic reverser lever

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

12F/12R transmission includes:

- Hydraulic wet clutches (forward and reverse)

- Maximize durability and outlast the life of any dry clutch

- When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs

- Platform-mounted shift levers (four gears, three ranges)

- Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience

- The gear-shift lever is easy to reach, and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two

- Left-hand reverser

- Constant-mesh helical-cut gears

- Provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability

- Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating

- Pressure-lubricated top shaft

- Positive park pawl: provides positive park and eliminates the need for a hand brake

- Neutral start switch

The forward lever selects one of four gears. The operator must depress the clutch while shifting. The rear lever selects one of three ranges: A, B, or C.

The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

The speed of directional changes can be adjusted to the operator's preference or application demands with the field-installed infinitely-variable control kit.

See the PTO functional area for more information on E-PTO.

Specs & Compare

Key Specs | 5090EL Current Model |

| Engine description | John Deere PowerTech 4045 |

| Engine displacement | 4 cylinders: 4.5 L 276 cu in. |

| Rated engine power | At 2400 per ISO 97/68/EC: 67.1 kW 90 hp |

| Maximum engine power | |

| Rated PTO power (hp SAE) | At 2400 per SAE: 52.2 kW 75 hp |

| Maximum PTO power | |

| Transmission type | Standard: 12F/12R PowrReverser Optional: 24F/12R PowrReverser |

| Hydraulic pump rated output | 85.1 L/min 22.5 gpm |

| Rear hitch category (SAE designation) | Category 2 |

| Base machine weight | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Engine specifications | |

| Description | John Deere PowerTech 4045 |

| Engine type | |

| Engine family | FJDXL04.5305 |

| Rated speed | |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | |

| After treatment type | |

| Displacement | 4 cylinders: 4.5 L 276 cu in. |

Engine performance | |

| Rated power | At 2400 per ISO 97/68/EC: 67.1 kW 90 hp |

| Rated PTO power (hp SAE) | At 2400 per SAE: 52.2 kW 75 hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | |

| Power boost | |

| Maximum engine power | |

| Engine peak torque | |

| Drawbar power | |

| PTO torque rise | |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Transmission | |

| Type | Standard: 12F/12R PowrReverser Optional: 24F/12R PowrReverser |

| Reverser | Yes |

| Clutch; wet/dry | Wet |

| Creeper | Not available |

Hydraulic system | |

| Type | Open center |

| Pump rated output | Standard: 85.1 L/min 22.5 gpm |

| Available flow at a single rear SCV | 60.1 L/min 15.9 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | 2; up to 3 |

| Number of mid selective control valves (SCVs) | 2; up to 3 |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | Optional |

| Auxiliary hydraulic features | |

| SCV control | |

Rear hitch | |

| Hitch draft control load sense type | Mechanical |

| Remote control valves available | 2; up to 3 |

| Hitch category (SAE designation) | Category 2 |

| Maximum lift capacity behind lift points | 1457 kg 3213 lb |

| Lift capacity at standard frame | |

| Sensing type | Top link |

| Rear axle differential lock | |

Drawbar | |

| Drawbar category | |

| Maximum vertical load | |

Rear power take-off (PTO) | |

| Type | Standard: 540/540E Optional: 540/1000 |

| Engine rpm (at rated PTO speeds) | 540 at 2400 rpm 540E at 1716 rpm 1000 at 2400 rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electrohydraulic |

Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

Rear axle | |

| Type | Inboard planetary |

| Final drive type | |

| Differential controls | Mechanical (pedal) |

| Axle type | Flanged |

| Brakes, type and control | Hydraulic wet disc |

| Rear differential lock | |

| Load rating | |

Front axle | |

| Type | |

| Front axle differential lock | |

| Load rating | |

Tires | |

| Rear | 19.5L-24 in. 10PR R4 Bias |

| Wheel tread range | Front: 1705-1834 mm 67.1-72.2 in. |

| Turning radius with brakes | 3.7 m 12.1 ft |

| Turning radius without brakes | 4.2 m 13.8 ft |

| Central Tire Inflation System (CTIS) | |

| Front | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | |

| Battery options | |

| Working lights | |

| Type of bulb in headlight (Halogen, Zenon, LED) | |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | |

Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Straddle Gearshift location - console/floor Floor |

| Seat | |

| Cab suspension | |

| Instructional seat | |

| Display | |

| Radio | |

| Inner cab volume | |

| dB(A) rating | |

| Cab glass area | |

| Safety glass rating | |

| Front visibility | |

Dimensions | |

| Wheelbase | 2350 mm 92.5 in. |

| Overall width | |

| Overall length | |

| Overall height | |

| Drawbar clearance | |

| Front axle center | |

| Approximate shipping weight, Open;Cab | Open: 3200 kg 7055 lb Cab: N/A |

Weight | |

| Base machine weight | |

| Maximum ballast level | |

| Maximum permissible weight | |

Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard: Open: 112.6 L 29.7 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | |

| Cooling system | |

| Transmission-hydraulic system | |

Serviceability | |

| Interval for engine oil change | |

| Interval for hydraulic/transmission oil change | |

| Interval for engine coolant change | |

Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Leveling type | |

Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

Miscellaneous | |

| AutoTrac ready | |

| ISOBUS ready | |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | Mexico |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

Drawbar

Lighting

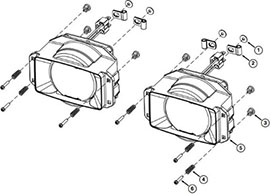

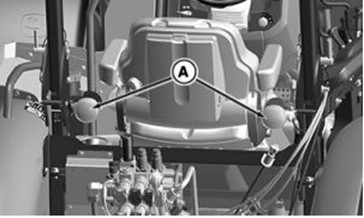

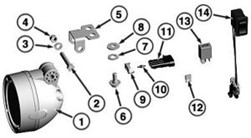

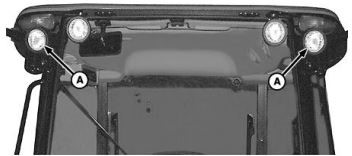

BSJ10325 LED Headlights shown

BSJ10325 LED Headlights shown

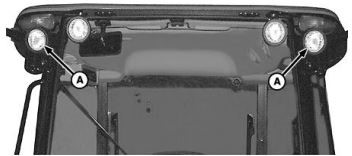

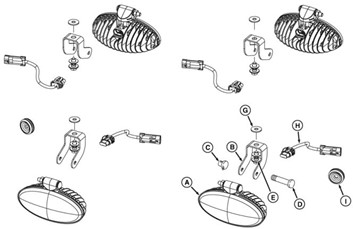

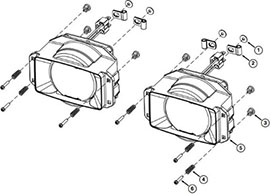

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown

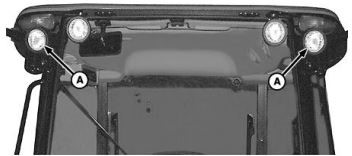

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

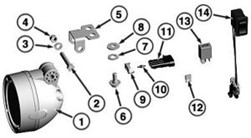

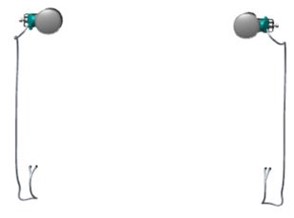

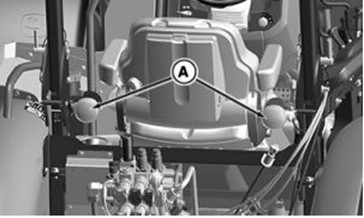

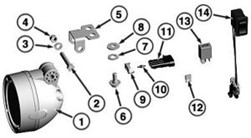

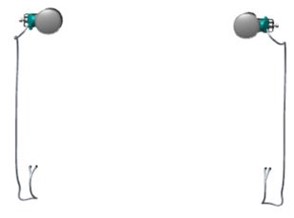

BSJ10056 Cab Auxiliary Work Light shown

BSJ10056 Cab Auxiliary Work Light shown

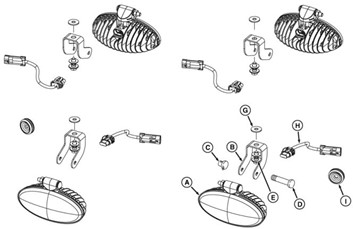

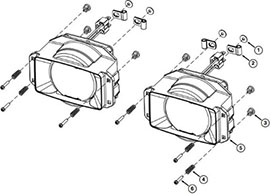

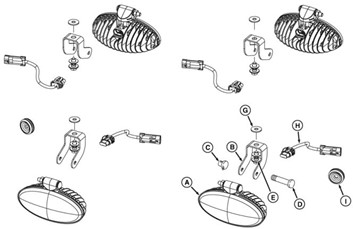

BSJ10163 Led Light Kit Shown

BSJ10163 Led Light Kit Shown

BSJ10478 LED Rear Work Light kit shown

BSJ10478 LED Rear Work Light kit shown

LVB25547 Rear Work Light shown on 5E tractor

LVB25547 Rear Work Light shown on 5E tractor

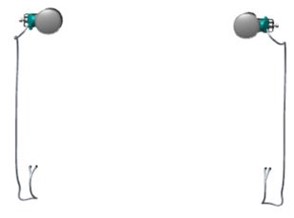

BSJ10420 Work Light Kit shown

BSJ10420 Work Light Kit shown

RE228854 Work Light Kit shown in forward facing mounting position

RE228854 Work Light Kit shown in forward facing mounting position

Overview

Work light kits offer additional light for increased visibility while working in dark conditions.

Benefits

- Adjustable lights for placing light where you need it

- OEM quality lights

- Increased light output

BSJ10325 LED Headlights shown

BSJ10325 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BSJ10056 Cab Auxiliary Work Light shown

BSJ10056 Cab Auxiliary Work Light shown

BSJ10163 Led Light Kit Shown

BSJ10163 Led Light Kit Shown

BSJ10478 LED Rear Work Light kit shown

BSJ10478 LED Rear Work Light kit shown

LVB25547 Rear Work Light shown on 5E tractor

LVB25547 Rear Work Light shown on 5E tractor

BSJ10420 Work Light Kit shown

BSJ10420 Work Light Kit shown

RE228854 Work Light Kit shown in forward facing mounting position

RE228854 Work Light Kit shown in forward facing mounting position

Overview

Work light kits offer additional light for increased visibility while working in dark conditions.

Benefits

- Adjustable lights for placing light where you need it

- OEM quality lights

- Increased light output

BSJ10325 LED Headlights shown

BSJ10325 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BSJ10056 Cab Auxiliary Work Light shown

BSJ10056 Cab Auxiliary Work Light shown

BSJ10163 Led Light Kit Shown

BSJ10163 Led Light Kit Shown

BSJ10478 LED Rear Work Light kit shown

BSJ10478 LED Rear Work Light kit shown

LVB25547 Rear Work Light shown on 5E tractor

LVB25547 Rear Work Light shown on 5E tractor

BSJ10420 Work Light Kit shown

BSJ10420 Work Light Kit shown

RE228854 Work Light Kit shown in forward facing mounting position

RE228854 Work Light Kit shown in forward facing mounting position

Overview

Work light kits offer additional light for increased visibility while working in dark conditions.

Benefits

- Adjustable lights for placing light where you need it

- OEM quality lights

- Increased light output

Operator's Station

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Power Take-Off (PTO)

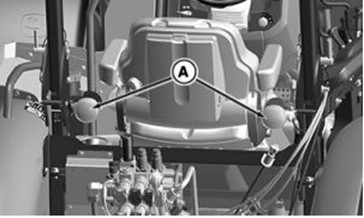

5M reversible PTO stub shaft shown

5M reversible PTO stub shaft shown

Overview

From mowing to baling to feed mixing and snow throwing, operators can operate an implement requiring 1000 rear PTO rpm or easily switch to 540 rpm to get the job done. Switching between 540 and 1000 rpm requires only removing a snap ring, flipping around the reversible shaft, replacing the snap ring, and shifting to the correct PTO speed. The dry cavity design makes this a less-mess, no-stress process without any oil spillage. The 5E 4-cylinder PTO rpm kits convert the factory two speed (540/540E rpm) to a two speed (540/1000 rpm), while the 5M kits upgrade the two speed (540/540E rpm) to a three speed (540/540E/1000 rpm), enabling more versatility.

Benefits

- Easily switch between implements requiring 540 and 1000 rpm PTO by simply reversing the interchangeable PTO shaft – no additional shafts or parts are needed.

- Less-mess, no-stress changeover process with a dry cavity design enhances productivity and increases uptime.

- 5M Tractors retain the ability to utilize a 540 Economy (540E) PTO, translating to fuel savings.

- NOTE: See the PTO detailed feature section for more information on E-PTO.

Additional details

|

|

A = snap ring B = snap ring groove C = bore |

| Reversible stub shaft (6 and 21 splines) | ||

To switch between 540 and 1000 speeds, simply remove the snap ring, flip the PTO shaft, and reinstall the snap ring. The tractor PTO operates at 540-rpm speed when the six-spline end of the shaft is visible, and at 1000-rpm speed when the 21-spline end of the shaft is visible.

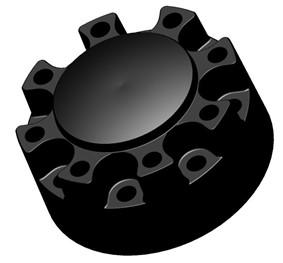

Wheel Tread Width

L154682 Spacer shown

L154682 Spacer shown

L154683 Spacer shown

L154683 Spacer shown

L154684 Spacer shown

L154684 Spacer shown

AL156776 Spacer shown

AL156776 Spacer shown

AL156779 Spacer shown

AL156779 Spacer shown

Overview

Axle spacers allow the tractors track width to be adjusted to improve row spacing and crop clearances.

L154682 Spacer shown

L154682 Spacer shown

L154683 Spacer shown

L154683 Spacer shown

L154684 Spacer shown

L154684 Spacer shown

AL156776 Spacer shown

AL156776 Spacer shown

AL156779 Spacer shown

AL156779 Spacer shown

Overview

Axle spacers allow the tractors track width to be adjusted to improve row spacing and crop clearances.

L154682 Spacer shown

L154682 Spacer shown

L154683 Spacer shown

L154683 Spacer shown

L154684 Spacer shown

L154684 Spacer shown

AL156776 Spacer shown

AL156776 Spacer shown

AL156779 Spacer shown

AL156779 Spacer shown

Overview

Axle spacers allow the tractors track width to be adjusted to improve row spacing and crop clearances.

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By