Features

High ground clearance protects crops

High ground clearance protects crops

Overview

High-value crop applications require the ability to pull implements and perform harvesting operations over rows of varying widths without damaging the crop. The 6120EH High-Crop Tractor delivers 77-cm (30-in.) of drawbar ground clearance to protect the plants and roots during applications such as cultivating, spraying, transplanting, and harvest.

Benefits

- Protection for crop plants and roots

- Additional crop clearance

- Adjustable tread for variable row spacing

Additional details

The 6120EH Tractor offers front and rear radial tire options similar to the current 6E Tractor lineup. This tire design provides better ride quality, less compaction, and efficiency converting power to the ground. The tire options available on the 6120EH are further designed to protect high-value crop operations by providing drawbar ground clearance from 63.5 cm to 76.2 cm (25 in. to 30 in.).

Front and rear tire size options include:

- 340/85R38 R2 Radial

- 230/95R48 R1W Radial

- 320/90R46 R2 Radial

- 320/90R50 R1W Radial

Tread spacing on 6EH Tractor

Tread spacing on 6EH Tractor

The tire tread can be set for premium utilization in operations with a variety of crop row spacing. The drop axle features a flanged-type axle end that supports main tread setting options from 183 cm to 213 cm (72 in. to 84 in.). This design assists in keeping the inner area of the wheels clear to avoid damaging the crops.

Crop row spacing |

Tractor tread spacing |

91 cm (36 in.) |

183 cm (72 in.) |

97 cm (38 in.) |

193 cm (76 in.) |

102 cm (40 in.) |

203 cm (80 in.) |

107 cm (42 in.) |

213 cm (84 in.) |

6EH Tractor operating in the field

6EH Tractor operating in the field

The 6E Series PowrReverser transmissions deliver unmatched performance. Operators who utilize power take-off (PTO) implements during high-value crop operations like harvesting and spraying will appreciate the range of working speeds provided by the PowrReverser transmission.

The 12F/12R PowrReverser transmission with creeper provides an additional ultra-slow speed and is conveniently managed on the left-hand side of the operator seat. The creeper feature benefits specialty applications such as vegetable and fruit farms that require ultra-slow speeds. The creeper transmission allows for speeds as low as 0.23 km/h (0.14 mph) to accommodate hand harvesting operations.

Benefits:

- Provides ultra-slow speed

- Matched for human walking speeds

- Ideal use for harvesting machines

Creeper control on 6120EH Tractor

Creeper control on 6120EH Tractor

Premium light kit on 6120EH Tractor

Premium light kit on 6120EH Tractor

To further enhance visibility, the 6120EH Tractor has the option to include light-emitting diode (LED) lights. With LED lights on the front hood and cab of the tractor, performing tasks in variable operating conditions is made easier. Operators can do any operation, such as apply chemicals, in low light conditions.

Benefits:

- Visibility

- Productivity

- Comfort

6EH Tractor pulling an implement with 3-point hitch

6EH Tractor pulling an implement with 3-point hitch

A Category 2 3-point hitch on the 6E High-Crop Tractor provides the lift capacity and versatility needed throughout operations. Hooking up implements is convenient with telescoping draft links and adjustable sway bars. The external cylinders provide for a hitch lift capacity of 3702 kg (8161.5 lb) at lift point and 3420 kg (7540 lb) at 610 mm (24 in.) behind the hitch-lift balls throughout the lifting range. These features make the 6120EH Tractor able to perform in a variety of different applications.

- Pulling harvester wagons

- High value crop harvesting

- Spraying

- Transplanting

- Cultivating

6120EH Tractor with 3-point hitch and sway bars

6120EH Tractor with 3-point hitch and sway bars

Gen 4 display in the tractor cab

Gen 4 display in the tractor cab

The Gen 4 Universal Display and AutoTrac activation leverages the simple modern interface offered with the Gen 4 family of displays. With a Gen 4 display, the StarFire™ 6000 Receiver determines the level of AutoTrac system accuracy. The Gen 4 AutoTrac activation for 6120EH Tractors supports SF3 and RTK.

Benefits:

- Extensive tracking options with AutoTrac

- Advanced guidance line creation and operation

- Informed operators

StarFire 6000 Receiver on the 6120EH Tractor

StarFire 6000 Receiver on the 6120EH Tractor

6120EH Tractors come with the option to include the John Deere StarFire 6000 Receiver. The StarFire 6000 Receiver expands on the value that precision agriculture growers have come to expect from StarFire products. The StarFire 6000 Receiver is equipped with an antenna, the latest in Global Navigation Satellite System (GNSS) signal processing technology, and a differential correction signal. This technology adds up to improved performance and uptime as well as lowers the cost of operation when paired with precision agriculture systems such as the AutoTrac™ assisted steering system.

Benefits:

- Customize accuracy

- Repeatability to meet the needs of the operation

- Get started faster with improved pull-in performance

- Maximize uptime to keep the job moving

When producers buy John Deere equipment, they expect reliability. They also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert the producer and dealer promptly – in the cab or anywhere they are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to the machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

Decrease interruptions to work with John Deere Connected Support

Decrease interruptions to work with John Deere Connected Support

With permission, John Deere Connected Support:

- Keeps operators running by monitoring machine health and promptly alerting the producer and dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep producers running as John Deere and John Deere dealers can.

Overview

Front and rear radial tire offerings are available on all models, except for the front tires on the open-operator station (OOS) configurations.

6E with radial tire offering

6E with radial tire offering

Benefits

- Better ride quality

- Better wear characteristics

- Less compaction

- More efficient converting more power to the ground

- Heavy-duty front rims are also available that are capable of additional load and are perfect for roadside mowing or sidehill applications

Additional details

Tire combinations by model

| Codes | 6105E | 6120E | 6120EH | 6135E | |

| 2WD front | |||||

| 6151 | 10.00-16 in. 8PR F2 bias | X | X | --- | --- |

| 2WD rear | |||||

| 5212 | 460/85R34 in. 8PR R1W radial | X | X | --- | --- |

| 5225 | 420/85/R38 in. 8PR R1W radial | X | X | --- | X |

| 5234 | 460/85R38 in. 8PR R1W radial | X | X | --- | X |

| Mechanical front-wheel drive (MFWD) front | |||||

| 6210 | 340/85R24 in. 8PR R1W radial | X | X | --- | X |

| 6200 | 320/85R24 R1W radial | X | X | --- | X |

| 6217 | 320/85R32 R1W | X | X | --- | X |

| 6218 | 340/85R24 R1W heavy-duty rim | X | X | --- | X |

| 6220 | 380/85R24 in. 8PR R1W radial | X | X | --- | X |

| 6222 | 380/85R24 R1W heavy-duty rim | X | X | --- | X |

| 6212 | 320/90R46 in 148A8 R2 radial | --- | --- | X | --- |

| 6213 | 320/90R50 in 147A8 R1W radial | --- | --- | X | --- |

| 6214 | 340/85R38 R2 radial | --- | --- | X | --- |

| 6295 | 230/95R48 in TL R1W radial | --- | --- | X | --- |

| MFWD rear | |||||

| 5212 | 460/85R34 in. 8PR R1W radial | X | X | --- | X |

| 5225 | 420/85/R38 in. 8PR R1W radial | X | X | --- | X |

| 5234 | 460/85R38 in. 8PR R1W radial | X | X | --- | X |

| 5460 | 300/95R42 TL R1, 147A8 radial | X | X | --- | X |

| 5521 | 320/90R50 R1W radial | X | X | X | X |

| 5223 | 320/90R46 in 148A8 R2 radial | --- | --- | X | --- |

| 5567 | 340/85R38 R2 Radial | --- | --- | X | --- |

| 5295 | 230/95R48 In. TL R1W Radial | --- | --- | X | --- |

Overview

To further the versatility and efficiency of the 6E Tractors and their hydraulic capabilities, the 6Es (excluding 6120EH) can be ordered loader ready. Being able to add a loader to a 6E Tractor makes it an even more capable solution to the various tasks a utility tractor is challenged with.

Mechanical joystick with dual-function mid-mount valve

Joystick installed in cab tractor

Joystick installed in cab tractor

Overview:

For the operator wanting to install a loader on a tractor, two-function and three-function hydraulic mid-mount valves with mechanical joystick are available.

Benefits:

The operator can operate the loader using a joystick, increasing productivity and maneuverability

Available for both cab and open operator station (OOS) configurations on all 6Es (excluding 6120EH)

Quick installation of a loader once the tractor is received

Improved resale value

NOTE: To field install the single-function lever controls (both two and three function) please refer to the loader Sales Manual and Price Pages.

Tractor models and horsepower

PowerTech engine

PowerTech engine

Overview

All John Deere 6E Series Tractors feature the reliable and proven 4.5L (275-cu in.) engines. These engines deliver constant power over a wide range of rpm with a power bulge above rated power and excellent torque characteristics.

The 6E Series, while being value-featured and competitively priced, are built with John Deere's long-standing reputation for reliability, durability, and maintainability.

Model |

Displacement |

Rated power take-off (PTO) power 2100 rpm |

Rated engine power 97/68/EC standard |

6105E |

4.5 L (275 cu in.) |

66 kW (89 hp) |

77 kW (105 hp) |

6120E(H) |

4.5 L (275 cu in.) |

76 kW (102 hp) |

88 kW (120 hp) |

6135E |

4.5 L (275 cu in.) |

86 kW (115 hp) |

99 kW (135 hp) |

Rated engine horsepower ratings are included for reference to competitor's gross or engine-only power ratings. There are several ratings systems used by other manufacturers. John Deere uses the horsepower-rating standard 97/68/EC, which is widely used in Europe for various regulations.

How is engine-only rated and maximum power determined?

John Deere engineering uses a precise procedure to measure engine-only power levels. The 97/68/EC standard is required in the European Union (EU) as an emission test, so there is some relation to the power a tractor has as a whole functioning unit; however, the procedure requires only that a production engine and radiator are used on a dynamometer test. Use the 97/68/EC horsepower ratings in the above chart to compare to competitor claims of engine-only power.

Benefits of PTO power and power bulge

The John Deere exclusive single-injector control, electronic fuel injection system, and other key engine parts work together to sense engine load and instantly respond as needed to pull through tough spots. This reduces engine rpm fluctuation, resulting in the reduced need to downshift the transmission. Fewer shifts result in fewer ground variations, providing more overall tractor productivity.

To match the engine power characteristics and improve economy of operation, the rated engine speed is 2200 rpm.

Feature and benefit overview

High-pressure common rail fuel system

- Higher injection pressures (up to 1896 bar [27,500 psi]), precise variable injection pressure, variable timing control, multiple injections

Four-valve cylinder head

- Crossflow head design provides excellent breathing from a lower-cost four-valve cylinder head.

Turbocharged

- In turbocharged engines, the air is pre-compressed. Due to the higher pressure, more air is supplied into the combustion chamber, allowing a corresponding increase in fuel injection which results in greater engine output.

Turbochargers

- Precisely matched to the power level and application, the 6Es are equipped with a wastegate (to divert exhaust gases) turbo.

Air-to-air intercooling

- This is most efficient method of cooling intake air to help reduce engine emissions while maintaining low speed torque, transient response time, and peak torque. It enables the engine to meet emission requirements with better fuel economy and the lowest installed costs.

Compact size

4.5 L (275 cu in.), 4 cylinders

Engine performance

- Power bulge feature

- Increased low-speed torque

- Multiple rated speeds to further reduce noise and improve fuel economy

- Higher peak torque ratings

- Faster torque rise

John Deere electronic engine controls

Monitors critical engine functions providing warning and/or shutdown to prevent costly engine repairs; eliminates need for add-on governing components; all lowering total installed costs

Snapshot diagnostic data that can be retrieved using commonly available diagnostic service tools

Common wiring interface connector for vehicles or available OEM instrumentation packages; solid conduit and T-connectors to reduce wiring stress and improved durability and appearance

Factory-installed engine-mounted engine control unit (ECU), wiring harness, and associated components; industry standard SAE J1939 interface which communicates with other vehicle systems, eliminating redundant sensors and reducing vehicle total installed cost

Additional features

- Self-adjusting, poly v-fan drive

- Forged-steel connecting rods

- Replaceable wet-type cylinder liners

- 500-hour oil change

Details:

Engine performance

| Model | 6105E | 6120E(H) | 6135E |

| Environmental Protection Agency (EPA) tier level | Final Tier 4 (FT4) | FT4 | FT4 |

| Engine model | 4045H | 4045H | 4045H |

| 97/68/EC at rated speed | 77 kW (105 hp) | 88 kW (120 hp) | 99 kW (135 hp) |

| Rated engine speed | 2200 rpm | 2200 rpm | 2200 rpm |

| PTO operating speed | 2100 rpm | 2100 rpm | 2100 rpm |

| Maximum torque engine speed | 1600 rpm | 1600 rpm | 1600 rpm |

| Fast idle speed | 2275+10 rpm | 2275+10 rpm | 2275+10 rpm |

| Low idle speed | 900+10 rpm | 900+10 rpm | 900+10 rpm |

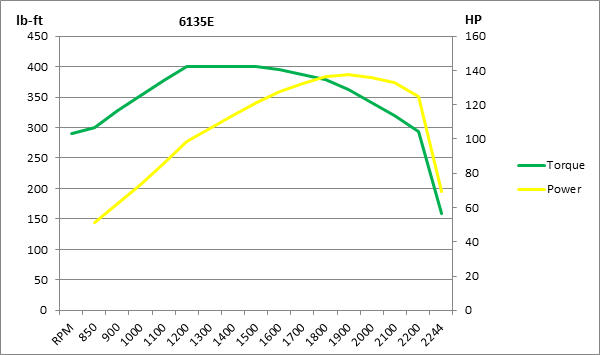

Torque curves

6135E torque curves graph

6135E torque curves graph

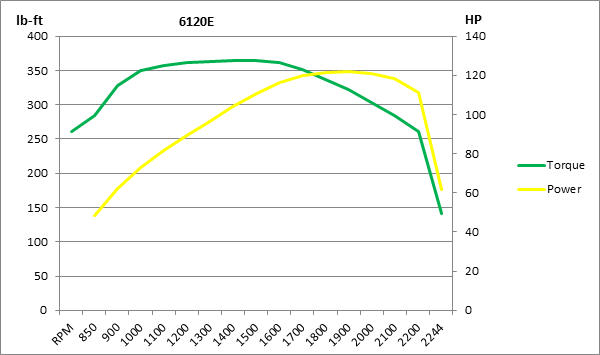

6120E(H) torque curves graph

6120E(H) torque curves graph

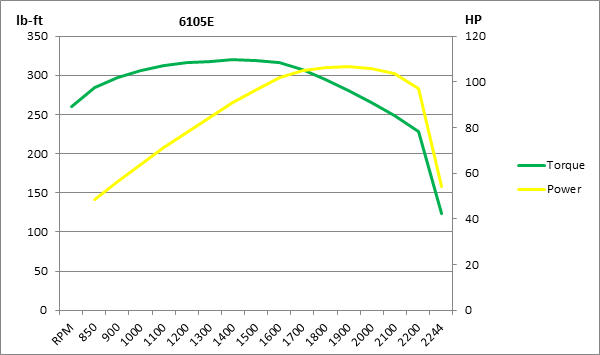

6105E torque curves graph

6105E torque curves graph

Service intervals

John Deere engines are designed and manufactured to deliver excellent reliability. The recommended service intervals of the engine should be coordinated with the tractor service intervals.

| Engine break-in service | 500 hours maximum with factory ship away oil and filter change |

| Engine oil & filter change | 250 hours – oil and filter change |

| Engine oil filter change | With oil change |

| Engine fuel filter change | As required, 500 hours, or yearly |

| Drain water separator | Check and drain daily or every 10 hours |

| Engine coolant change | 5 years or 5000 hours with John Deere Cool-Gard™ II and annual coolant tests |

| Engine coolant conditioner | As required every 500 hours |

| Diesel particulate filter (DPF) cleaning interval | As required |

| DPF and diesel oxidation catalyst (DOC) replacement | As required |

Open crankcase ventilation (OCV) |

1500 hours |

| Diesel exhaust fluid (DEF) filter replacement | Every 3 years or 4500 hours |

Engine specifications

| Model | 6105E | 6120E(H) | 6135E |

| Engine | PowerTech PWL | PowerTech PWL | PowerTech PWS |

| Engine model | 4045H | 4045H | 4045H |

| Size | 4.5 L (275 cu in.) |

4.5 L (275 cu in.) | 4.5 L (275 cu in.) |

| Number of cylinders | 4 | 4 | 4 |

| Valves per cylinder | 4 | 4 | 4 |

| Aspiration | Turbo and aftercooled | Turbo and aftercooled | Turbo and aftercooled |

| Engine management | Electronic | Electronic | Electronic |

| Fuel delivery | High-pressure common rail (HPCR) | HPCR | HPCR |

| Rated engine speed | 2200 rpm | 2200 rpm | 2200 rpm |

| PTO operating speed | 2100 rpm | 2100 rpm | 2100 rpm |

| Maximum torque operating speed | 1600 rpm | 1600 rpm | 1600 rpm |

| Fast idle speed | 2275 rpm | 2275 rpm | 2275 rpm |

| Low idle speed | 900 rpm | 900 rpm | 900 rpm |

| Rated PTO power | 66 kW (89 hp) at 2100 rpm |

76 kW (102 hp) at 2100 rpm |

86 kW (115 hp) at 2100 rpm |

| Rated engine power | 77 kW (105 hp) at 2200 rpm [97/68/EC] | 88 kW (120 hp) at 2200 rpm [97/68/EC] | 99 kW (135 hp) at 2200 rpm [97/68/EC] |

| Power bulge | 3 percent at 2000 rpm | 3 percent at 2000 rpm | 3 percent at 2000 rpm |

| Peak torque | 432 Nm (318 lb-ft) at 1600 rpm | 494 Nm (364 lb-ft) at 1600 rpm | 538 Nm (397 lb-ft) at 1600 rpm |

| Torque rise | 29 percent at 2200 | 29 percent at 2200 | 25 percent at 2200 |

| Compression | 16.8:1 | 16.8:1 | 16.8:1 |

| Bore x stroke | 11.9 x 12.7 cm (4.7 x 5 in.) | 11.9 x 12.7 cm (4.7 x 5 in.) | 11.9 x 12.7 cm (4.7 x 5 in.) |

Overview

The 6E Series PowrReverser transmissions deliver unmatched performance. This transmission is ideal for working in tight areas where forward to reverse shifting is a primary occurrence such as in barns, feedlots, and loader applications.

Producers who operate power take-off (PTO) implements like a rotary cutter or baler will appreciate the additional working speeds with the 24F/12R PowrReverser transmission. High and low buttons are used to make fine adjustments in speed without needing to use the clutch, delivering improved productivity.

The PowrReverser transmission provides 12 forward and 12 reverse speeds. Six well-spaced ground speeds place the operator in the important haying or rotary cutter range of 8 km/h to 20.9 km/h (5 mph to 13 mph). With this transmission, the operator can reach a top speed of 31.5 km/h (19.6 mph). The optional 24F/12R PowrReverser transmission delivers 11 well-spaced ground speeds to match the correct speed for a haying or rotary cutter application with a top speed of 40 km/h (25 mph).

A dash-mounted PowrReverser modulation kit (LVB25727) is available to set the aggressiveness of the forward and reverse shuttle modulation that best fits the application or the operator's comfort level.

Operator controls

Right-side controls

Right-side controls

Left-side controls

Left-side controls

Two levers, one for speed and one for range, with the addition of an electrohydraulic left-hand reverser, provide operators optimum control and maneuverability.

- Range lever (right-hand side [cab], left-hand side [OOS]) selects four ranges (A, B, C, D).

- Gear selection (right-hand side) selects speeds (1, 2, or 3) in the forward or reverse

- Electrohydraulic left-hand reverser allows for quick and convenient shuttle shifting between forward and reverse at any

- High and low buttons are located on the gear shifter for the 24F/12R PowrReverser

- 12F/12R creeper transmission speed control (left-hand side)

Benefits

Forward and reverse speeds

All speed gears (1, 2, 3) are fully synchronized for shifting-on-the-go capabilities, putting less wear on the operator and saving time in the field. In the 12F/12R PowrReverser transmission, gears are synchronized for low shifting effort while the operator is doing field or loader work and during transport.

The PowrReverser transmission lineup also consists of a 12F/12R transmission with creeper. The creeper transmission functionality provides an ultra-low speed to match ground speed during tasks such as harvesting high-value crops, particularly vegetables, that are hand harvested.

The high and low speeds on the 24F/12R PowrReverser transmission can be shifted without clutching while the tractor is under load. This makes for quick speed changes when operating a rotary cutter or baler.

To further enhance awareness of reverse tractor motion, a backup alarm can be field installed (BSJ10026).

The ranges (A, B) are not synchronized. This means the tractor must be stopped for the operator to select the range. However, with operator input, the speeds have been well spaced out to minimize the need to change ranges within applications. The ranges (B to C, C to D, and D to C) are synchronized. That allows the operator to shift ranges on the go in transport and high-speed applications like operating a mower-conditioner.

Wet clutch

John Deere has led the industry in the innovation of wet clutches. In this wet-clutch design, five 17-cm (6.7-in.) diameter clutch disks provide optimum clutch modulation for smooth operation; the disks are oil-cooled for a lifetime of service.

The biggest advantage of a wet clutch is its ease of use as the required force to depress the pedal is minimal. Also, with a wet clutch, the need for frequent adjustment and clutch mechanism changeover is eliminated.

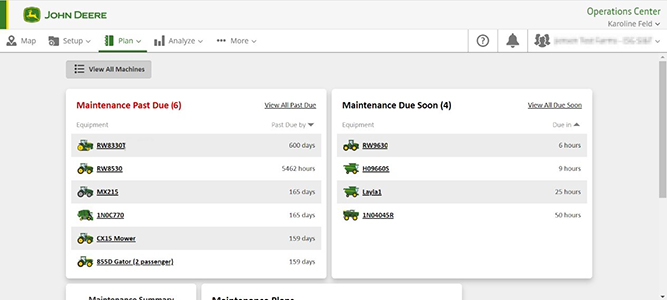

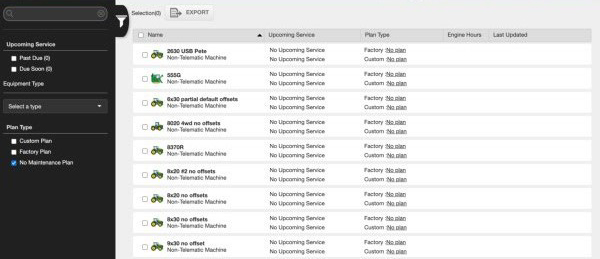

Maintaining your equipment is easy with Maintenance in John Deere Operations Center web.

- View current and past due maintenance with Maintenance in Operations Center web or in JDLink Mobile

- Use factory plans or create a custom plan for each machine

- View parts required for each interval

- Link to John Deere Parts to order parts

Maintenance in John Deere Operations Center web helps you manage maintenance for your equipment

Maintenance in John Deere Operations Center web helps you manage maintenance for your equipment

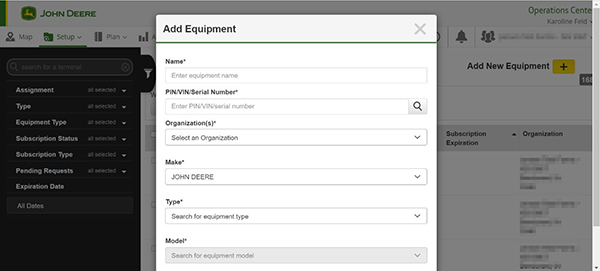

Add plans to non-telematic machines in Maintenance

Add plans to non-telematic machines in Maintenance

Use Terminals to add non-telematic machines to your organization

Use Terminals to add non-telematic machines to your organization

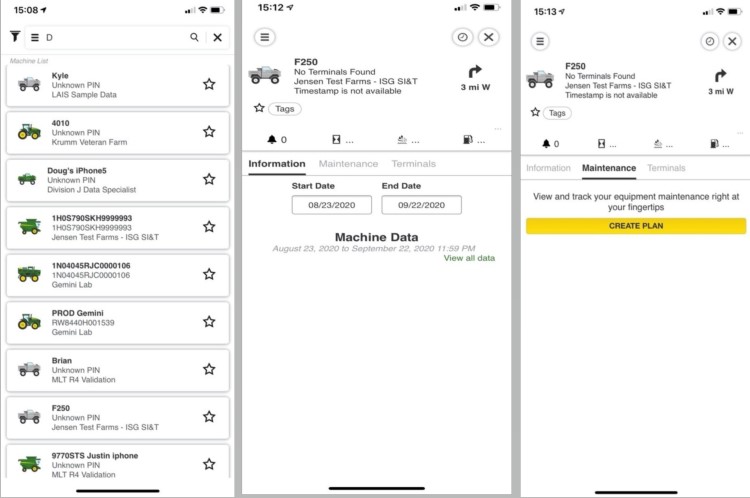

Use JDLink Mobile to view and edit maintenance plans

Use JDLink Mobile to view and edit maintenance plans

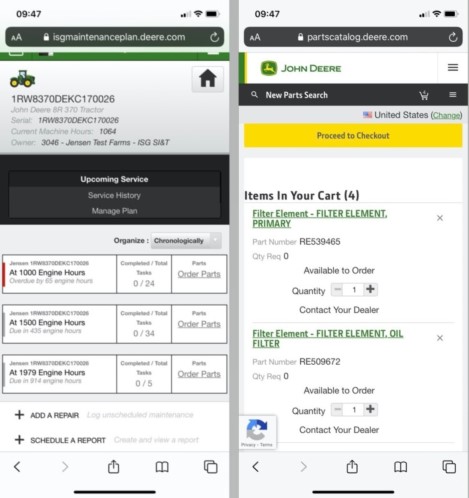

Select “Order Parts” to be directed to John Deere Parts and have the parts placed into your cart

Select “Order Parts” to be directed to John Deere Parts and have the parts placed into your cart

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

Specs & Compare

Offers & Discounts

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By