6R 120

Utility Tractor

- John Deere FT PowerTech™ 4-cylinder engines

- Engine HP: 132 HP Max/120 HP Rated with up to 20 additional HP (IPM)

- AutoQuad™ or IVT transmission

- Cat. 2/3N Hitch with lift capacity over 7,900lb.

View Product Brochure

Features

Operations Center

The John Deere Operations Center brings all your farm management data together in one place. Easy to understand, its integrated tools support your agronomic decision making and help you get maximum yield and consistent quality from your soil at significantly reduced input costs. Operations Center is how you turn valuable agronomic insights into smart decisions and easily define corrective actions. Other integrated tools let you create site-specific variable rate prescriptions and allow you to collaborate with agronomic advisors by granting them field-specific access rights. Documenting your work for clients also becomes a breeze with easily created, printed, and shared reports. What’s more, an Operations Center account is free to use no matter how big your operation is.

iTEC™ Pro

Intelligent Total Equipment Control integrates AutoTrac™ automatic steering and implement management systems to control tractor speed, front and rear mounted implements, and differential lock engagement, among other parameters. This allows for hands-free turns while reducing soil compaction, resulting in picture-perfect headlands and consistent crop growth.

JDLink™ system

See where your machines are and what they are doing with JDLink

See where your machines are and what they are doing with JDLink

JDLink shows where machines are, what they are doing, and how they are performing. You or your dealer can remotely assist operators with machine setup and operation leveraging Remote Display Access (RDA). JDLink connectivity additionally includes Wireless Data Transfer (WDT) for seamless data exchange between the machine and the office.

- Easily transfer data and collaborate with trusted advisors

- Better enable data-driven decisions

- Report work completed accurately and timely

- Increase machine uptime with Connected Support through remote monitoring services and diagnostics

- Get quick in-field support with RDA

- Remotely manage machines and employees to give you insights into how they are performing

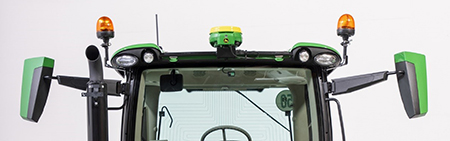

Guidance solutions

AutoTrac ready

John Deere AutoTrac system provides a hands-free guidance solution, helping to manage in-field efficiency and greatly reducing operator fatigue. The 6R Tractor comes from the factory as AutoTrac ready, which includes the software, sensors and valves to provide an integrated solution for the producer (receiver and activation are purchased separately). This allows producers to capture the value of guidance without the installation of labor-intensive kits.

AutoTrac Turn Automation

AutoTrac Turn Automation controls the entire headland turn and manages all tractor and implement functions, including forward speed changes and power take-off (PTO) switching. It raises or lowers the hitch or activates selective control valves (SCVs) at exactly the right time and position in the field to guarantee perfectly consistent headland crop growth.

AutoPath™ system

AutoPath automatically creates guidance lines for different width machines based on data gathered by the first pass of a tillage implement or planter. It takes charge of your guidance line management, protecting nutrient investment and helping you make each pass with confidence and precision. If you are using different width implements for planting, spraying, or harvesting, AutoPath ensures the tires always follow the planted rows and stay off the crop. When harvesting, the combine is always guided to the correct starting point, and the guidance lines are automatically calculated based on the width of the header.

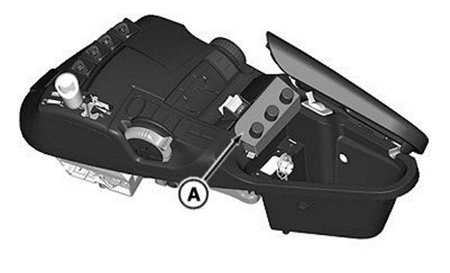

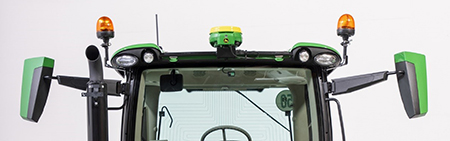

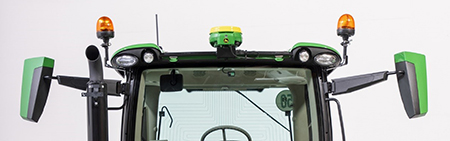

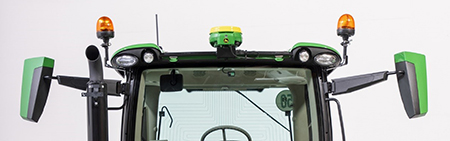

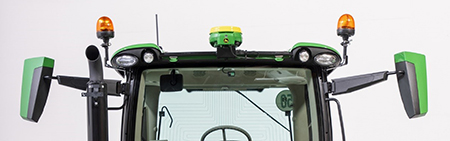

View of cab

View of cab

Operator station

The 6R Tractor cab delivers on comfort and convenience, regardless of your application. The all-around visibility and easy-to-use controls make the 6R a perfect fit for your operation. All 6R Tractors include a corner post display featuring state-of-the-art electronic instrumentation that blends well with the narrow right-hand cab post. This provides all the critical machine information and enhanced visibility. In addition, premium features such as automatic climate control, an instructor seat, and foot throttle come standard on the 6R Tractors.

CommandARM™ controls and Generation 4 CommandCenter™ display

CommandARM and Generation 4 CommandCenter display

CommandARM and Generation 4 CommandCenter display

The CommandARM console provides a thoroughly intuitive operating interface. All the controls you need for daily work are available at your fingertips: selective control valves (SCVs), AutoTrac™ automatic steering, iTEC™ machine control, air conditioning, lights, radio, four-wheel drive (4WD), and hitch depth control. Mounted on the CommandARM, the Generation 4 CommandCenter display has easy-to-use, tablet- like swipe functionality and monitors everything you need for productive and efficient work.

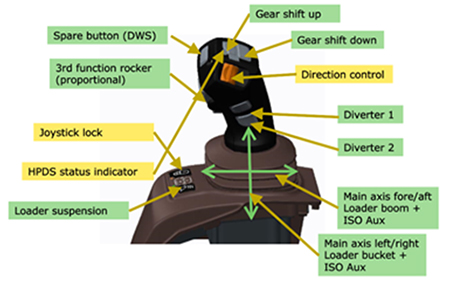

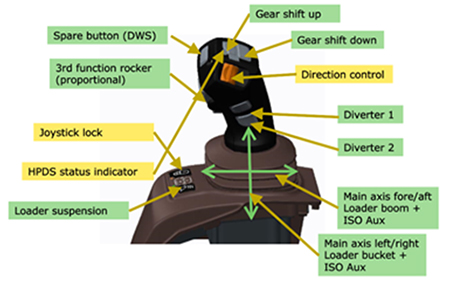

CommandPRO™ control

CommandPRO joystick

CommandPRO joystick

The CommandPRO joystick combines a unique driving strategy with reconfigurable controls. All the controls you need for daily work are available at your fingertips: travel speed, acceleration response, reconfigurable buttons and rocker switches, and activation button.

Generation 4 CommandCenter display with Extended Monitor

Gen 4 Extended Monitor

Gen 4 Extended Monitor

The Gen 4 Extended Monitor doubles the screen area so you can monitor more functions at once and have direct access to make adjustments when needed. You could, for example, view vehicle control functions on your primary display and Precision Ag applications on the Extended Monitor.

Operate the 6R Tractor with ease

Operate the 6R Tractor with ease

Operator Comfort

Triple-Link Suspension (TLS™)

TLS suspension

TLS suspension

The TLS Plus system provides optimal traction and field performance by maintaining ground-to-tire contact, enabling more power to the ground. It also ensures higher operator comfort, reduces operator fatigue, and increases productivity, while the Variable Ratio Steering improves in-field maneuverability.

Cab suspension

Cab suspension system

Cab suspension system

The intelligent hydropneumatic cab suspension offers more driving comfort in the field and on the road. Input from the acceleration and TLS sensor causes the cab suspension controller to increase or decrease the amount of oil in the shock absorber ram. This semi-active system delivers ultimate comfort in every situation.

Variable Ratio Steering

Variable Ratio Steering off

Variable Ratio Steering off

Variable Ratio Steering on

Variable Ratio Steering on

Variable Ratio Steering improves operator comfort, requiring less hand movement and less steering effort when turning on the headland or in confined spaces. This results in faster turning of the steering wheel and increases hydraulic flow, leading to a quicker response from the tires. The system can be activated or deactivated in the CommandCenter™ display and is available for all 6R Tractors.

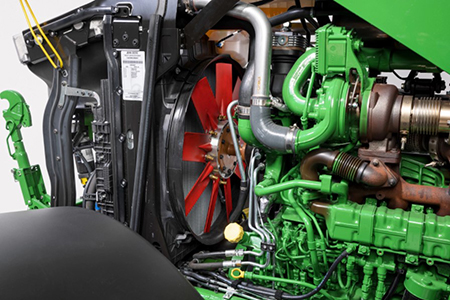

Engine

The high power output of the John Deere 4-cylinder, 4.5L (274.6-cu in.) engine and the 6-cylinder, 6.8L (415-cu in.) engine is made possible by refined, four-valve, high-pressure common rail (HPCR) technology with an injection pressure of up to 2500 bar (36,259.4 psi). The PVS engine in the 6R 175, 6R 195, and 6R 215 models is equipped with a variable geometry turbocharger (VGT) that boosts performance and efficiency consistently across the torque curve. The PSS engines (6R 230 and 6R 250) use a two-stage turbocharging system in which the VGT multiplies the pressure created by a fixed vane turbocharger.

Intelligent Power Management (IPM)

Intelligent Power Management (IPM) is a feature for many typical farming operations that use the rear power take-off (PTO) in high-power applications or the tractor as a transport vehicle. Operators who are looking for more power in non-stationary PTO and transport applications will be interested in the IPM feature. In high rear PTO power applications such as forage harvesters, rototillers, and beet or potato harvesting equipment or where heavy trailers, carts, or implements are moved to and from various locations, this feature provides significant additional capabilities. The solution improves productivity with more consistent ground speeds, quicker acceleration, and the ability to better hold desired transport speeds. All 6R Tractors have IPM in base equipment. Hydraulic IPM is available as a separate option to enable the IPM in applications resulting in high hydraulic loads.

Reversible fan

Reversible fan

Reversible fan

Optimize engine performance in dusty environments by utilizing the optional reversible fan technology available on all 6R Tractors. The reversible fan allows the operator to quickly clean radiator screens from the comfort of the cab. By manually activating the system with a switch in the cab, the radiator fan blades blow out dust and debris away from the radiator. This enables the engine to run cooler, resulting in fuel savings, less downtime, and overall increased efficiency.

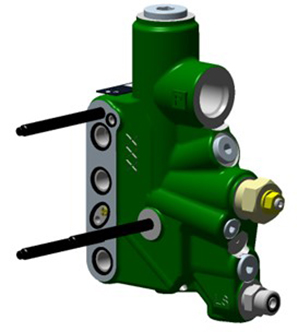

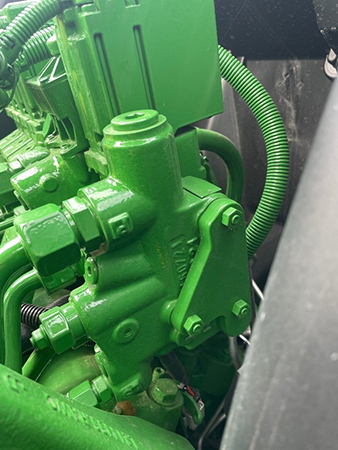

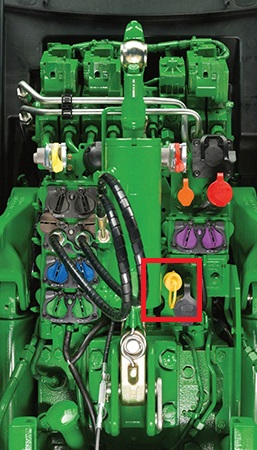

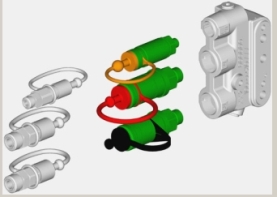

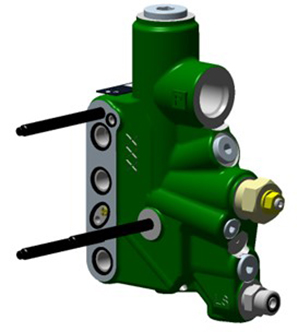

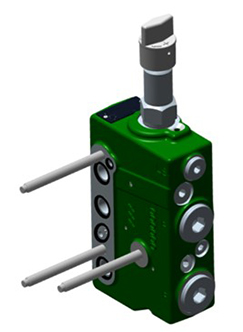

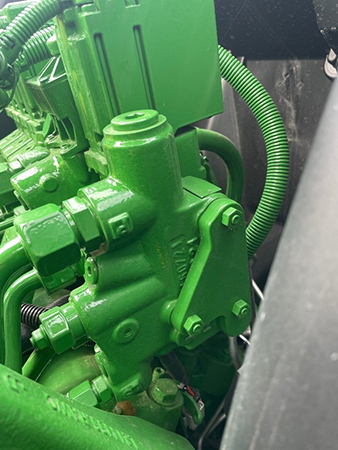

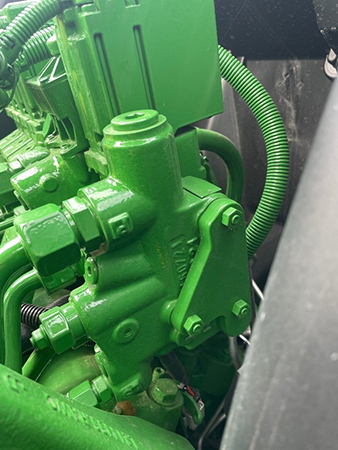

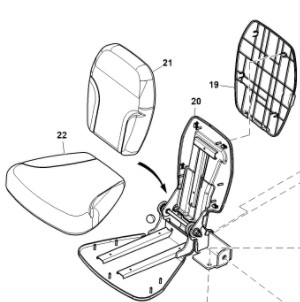

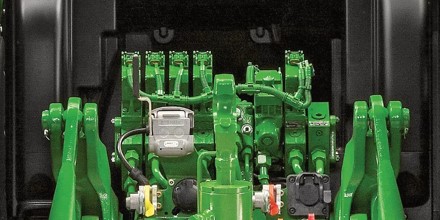

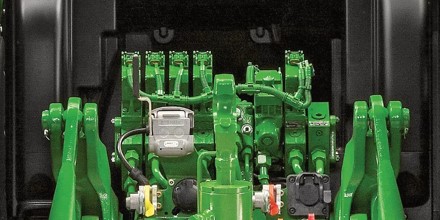

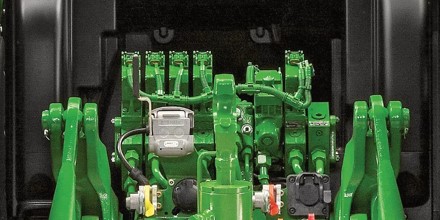

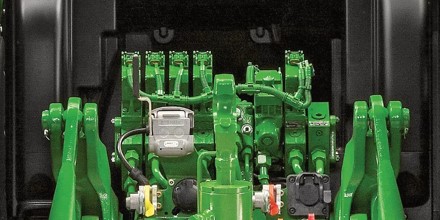

Hydraulic system

Hydraulic system

The closed-center, pressure-and-flow-compensated hydraulic system in the 6R Tractors has been engineered for maximum durability and reliability by optimizing the number of hydraulic components and connections, which also makes it extremely efficient. The system in the 6R 230 and 6R 250 delivers a powerful 160 L/min (42.3 gpm) at 1500 rpm with enhanced operating characteristics. In a 6R Tractor, you get up to six electrohydraulic selective control valves (SCVs) with a pressure relief lever, logically clustered, and all iTEC™ capable. You can easily control flow rates and times from the cab with the CommandCenter™ display.

Hydraulic Intelligent Power Management (IPM)

As a supplement to power take-off (PTO) and transport applications, Intelligent Power Management also delivers additional horsepower for hydraulically driven implements. The Hydraulic IPM keeps tractor wheel speed constant during applications that use power-hungry hydraulically driven implements like slurry tankers, sprayers, or manure spreaders.

AutoQuad™ transmission

6R Tractor

6R Tractor

The AutoQuad transmission has all the benefits of the PowrQuad™ PLUS transmission with the added convenience of automatic gear shifting. It is available in 20F/20R and 24F/24R versions. With the EcoShift option, a transport speed of 40 km/h (25 mph) is maintained at only 1533 rpm, reducing fuel consumption and emissions.

Enhanced AutoPowr™ transmission – Infinite speed adjustment in all situations

AutoPowr/IVT transmission

AutoPowr/IVT transmission

AutoPowr/IVT is a hydromechanical transmission that delivers stepless and continuous power at speeds between 40 km/h and 50 km/h (25 mph and 31 mph). The AutoPowr transmission maintains the selected speed by automatically responding to changing load conditions. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, thus reducing noise and saving fuel. A speed of 50 km/h (31 mph) is maintained at 1630 rpm, and a speed of 40 km/h (25 mph) is maintained at 1300 rpm with the CommandPRO™ joystick.

DirectDrive transmission – The benchmark for seamless efficiency

DirectDrive transmission

DirectDrive transmission

Specifically developed for 6R Tractors, DirectDrive is an eight-speed, three-range transmission designed and engineered by John Deere for heavy agricultural work. Super-efficient dual-clutch technology always has the next gear lined up, so there is no lost momentum during changes, fuel consumption is reduced, and ease of operation is assured. During transport, DirectDrive reduces the engine speed to 1550 rpm at 40 km/h (25 mph) and 1600 rpm at 50 km/h (31 mph), thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

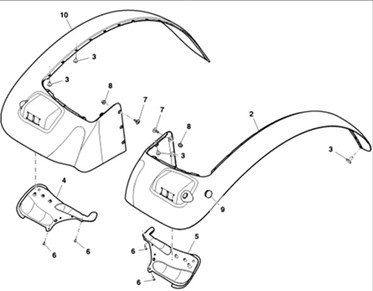

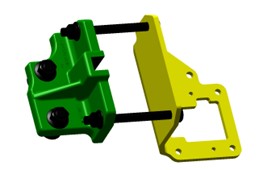

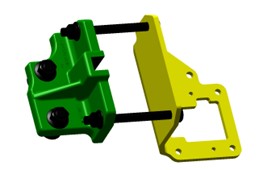

R Series Loaders

John Deere R Series Front Loaders have automatic latch designs, making the installation of loader and implements very efficient. John Deere loaders are built for productivity with little maintenance required. When combined with the maneuverability and technology of the 6R Tractors, operators enjoy proficient material handling and feeding in any application. An optional technology package boosts your productivity thanks to Return-to-Position and further enhances precision with the Dynamic Weighing System while preventing material losses thanks to the electronic Level-to-Horizon feature.

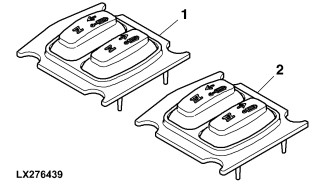

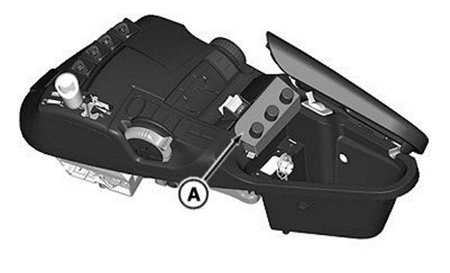

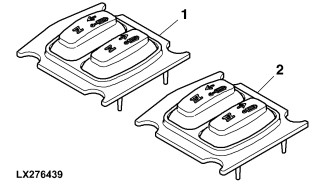

Electronic control with reverser

Optional electronic control

Optional electronic control

Joystick on the CommandARM™ console

Joystick on the CommandARM™ console

John Deere 6R Tractors have an optional electronic control with an integrated reverser. The loader control has five reconfigurable buttons and rocker switch for tractor and ISOBUS functions.

Loader technology

Dynamic Weighing System

Enhance your precision on the go. The Dynamic Weighing System provides the operator with real-time weights that enable the operator to fill the loader to a desired weight. This delivers efficiency by reducing unnecessary trips to the feed source and allows operators to effectively manage the right combination of inputs into feed rations.

Return to Position

Boost your productivity for repetitive tasks. With Return-to-Position you can save up to four implement positions for quick and comfortable recall with the loader control.

Level to Horizon

Level-to-Horizon functionality

Level-to-Horizon functionality

Prevent material losses while keeping your speed with the Level-to-Horizon feature, which keeps the loader attachment level in uneven terrain.

Specs & Compare

Key Specs | 6R 120 Current Model |

| Engine description | John Deere PowerTech™ PSS |

| Engine displacement | 4.5 L 275 cu in. |

| Rated engine power | |

| Maximum engine power | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | 97/68EC: 88 kW 120 hp |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | 97/68EC: 97 kW 130 hp |

| Rated PTO power (hp SAE) | 68 kW 91 hp |

| Maximum PTO power | |

| Transmission type | |

| Hydraulic pump rated output | Standard: 45 cc pump: 114 L/min 30 gpm |

| Rear hitch category (SAE designation) | Standard: Category 2/3N: 3600 kg 7937 lb Optional: Category 2/3N: 4100 kg 9039 lb |

| Base machine weight | 6100 kg 13,448 lb |

Engine specifications | |

| Description | John Deere PowerTech™ PSS |

| Engine type | Diesel, in-line, 4-cylinder, wet-sleeve cylinder liners with four valves in head |

| Engine family | NJDXL06.8324 |

| Rated speed | 2100 rpm |

| Aspiration | Turbocharged, fixed geometry first stage-variable geometry second stage, air-to-air aftercooling and cooled exhaust gas recirculation |

| Cylinders liners | |

| Emission level | Final Tier 4 |

| After treatment type | DOC/DPF/SCR |

| Displacement | 4.5 L 275 cu in. |

Engine performance | |

| Rated power | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | 97/68EC: 88 kW 120 hp |

| Rated PTO power (hp SAE) | 68 kW 91 hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | Transport and/or mobile PTO applications Additional engine power (hp ISO) at 2100 rpm: 14.9 kW 20 hp |

| Power boost | 10 percent |

| Maximum engine power | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | 97/68EC: 97 kW 130 hp |

| Engine peak torque | At 1600 rpm: 562 Nm 415 lb-ft |

| Drawbar power | |

| PTO torque rise | 40 percent |

| Fuel injection system and control | |

| Air cleaner type | |

Transmission | |

| Type | Standard: IVT, 0.05-42 km/h 0.03-26 mph Optional: IVT, 0.05-50 km/h 0.03-31 mph 24-speed AutoQuad PLUS ECO (40K) 24-speed AutoQuad PLUS ECO (50K) |

| Reverser | Left-hand electrical reverser |

| Clutch; wet/dry | |

| Creeper | Available with AutoQuad |

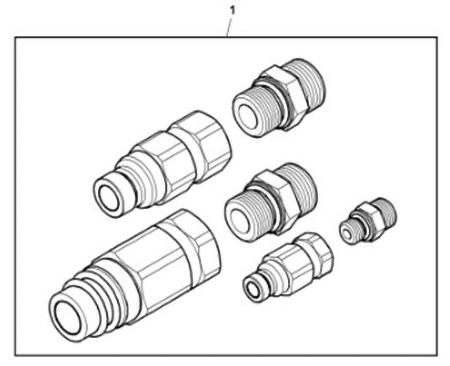

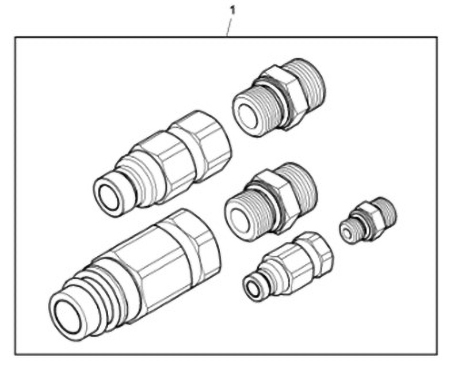

Hydraulic system | |

| Type | Closed-center, pressure-and-flow compensated |

| Pump rated output | Standard: 45 cc pump: 114 L/min 30 gpm |

| Available flow at a single rear SCV | 100 L/min 26 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Standard: Three ISO couplers Optional: Three to five ISO couplers |

| Number of mid selective control valves (SCVs) | Up to three |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | Available |

| Auxiliary hydraulic features | |

| SCV control | Standard: Mechanical Optional: Electronic |

Rear hitch | |

| Hitch draft control load sense type | |

| Remote control valves available | Available: Remote control switch |

| Hitch category (SAE designation) | Standard: Category 2/3N: 3600 kg 7937 lb Optional: Category 2/3N: 4100 kg 9039 lb |

| Maximum lift capacity behind lift points | 4100 kg 9039 lb |

| Lift capacity at standard frame | |

| Sensing type | Electrohydraulic |

| Rear axle differential lock | Electrohydraulic |

Drawbar | |

| Drawbar category | Category 2 |

| Maximum vertical load | Category 2: 1400-2450 kg 3085-5400 lb Maximum vertical load dependent on drawbar position |

Rear power take-off (PTO) | |

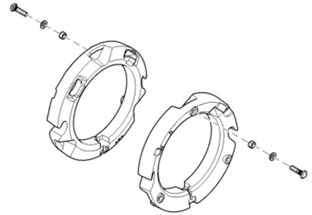

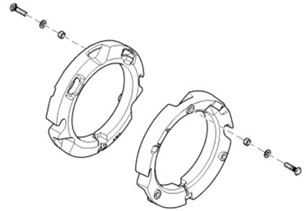

| Type | Independent Standard: 540, 540E, 1000 rpm reversible shaft: 35 mm 1.375 in. |

| Engine rpm (at rated PTO speeds) | 1967 engine rpm at 540 rpm PTO 1496 engine rpm at 540E rpm PTO 1962 engine rpm at 1000 rpm PTO |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electrical modulation |

Front hitch | |

| Category | Category 3N |

| Electric power | Seven-pin electrical socket Optional: Three-pin and ISOBUS socket |

| Standard lift capacity | At hook ends: 3300 kg 7275 lb |

| Front power take-off (PTO) | 1000 rpm, clockwise rotation (from driving position) |

| PTO speed | Engine at PTO speed (1000): 1969 rpm |

Rear axle | |

| Type | Standard: Flange, 1552 mm 61 in. Optional: Rack and pinion, 2550 mm 100.4 in. Rack and pinion, 2438 mm 96 in. |

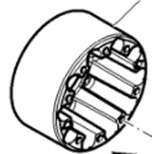

| Final drive type | Inboard planetary three pinion |

| Differential controls | Full-locking electrohydraulic |

| Axle type | |

| Brakes, type and control | |

| Rear differential lock | |

| Load rating | |

Front axle | |

| Type | |

| Front axle differential lock | MFWD: Limited slip TLS: Limited slip TLS with brakes: Full-locking electrohydraulic |

| Load rating | |

Tires | |

| Front | |

| Rear | 420/85R30 (16.9R-30) |

| Wheel tread range | MFWD: 1524-2235 mm 60-88 in. TLS: 1524-2235 mm 60-88 in. |

| Turning radius with brakes | |

| Turning radius without brakes | |

| Central Tire Inflation System (CTIS) | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | Standard: 120 amp Optional: 250 amp |

| Battery options | 12 V |

| Working lights | Standard: 14 halogen Optional: 12 light-emitting diode (LED) plus two halogen |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: 65-W halogen W Optional: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | 1200 CCA |

Operator station | |

| Rollover protective structure, OOS | |

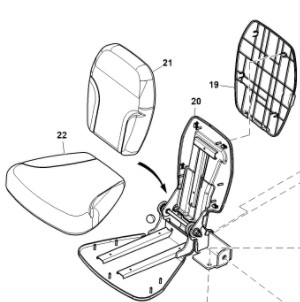

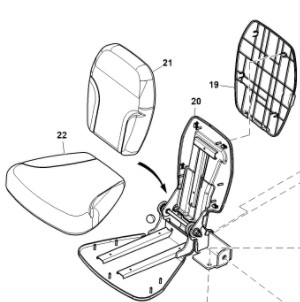

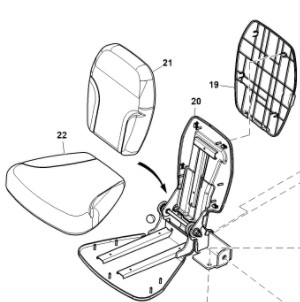

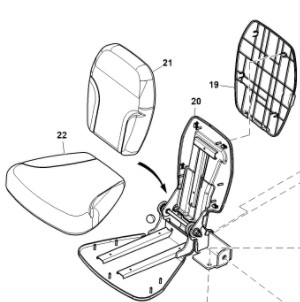

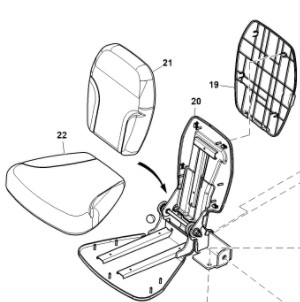

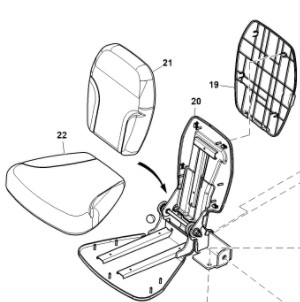

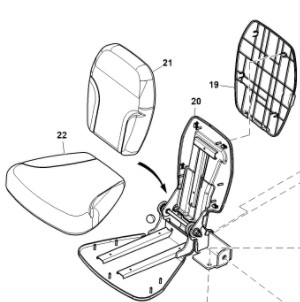

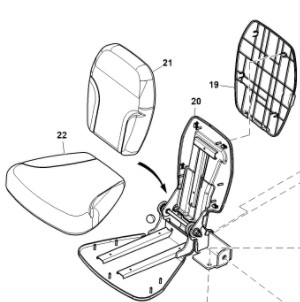

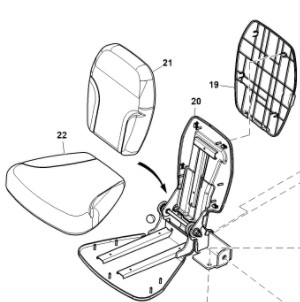

| Seat | Degree of seat swivel, left hand CommandARM: 7.5 degree Degree of seat swivel, right hand CommandARM: 30 degree Standard: Air suspension Optional: Deluxe air suspension |

| Cab suspension | Optional: Adaptive Hydraulic Cab Suspension Plus (HCS Plus) |

| Instructional seat | Standard |

| Display | |

| Radio | Optional |

| Inner cab volume | 3.33 m3 117.59 cu ft |

| dB(A) rating | 71 dB |

| Cab glass area | 6.11 m2 65.77 sq ft |

| Safety glass rating | |

| Front visibility | |

Dimensions | |

| Wheelbase | MFWD: 2580 mm 102 in. |

| Overall width | 1680 mm 66.1 in. |

| Overall length | 4533 mm 178.5 in. |

| Overall height | 2886 mm 113.6 in. |

| Drawbar clearance | |

| Front axle center | 481 mm 18.9 in. |

| Approximate shipping weight, Open;Cab | 6100 kg 13,448 lb |

Weight | |

| Base machine weight | Front axle 2440 kg 5379 lb Rear axle 3660 kg 8069 lb Total TLS, AutoQuad, 600/65R38, 540/65R24, shipping fuel, front weight support: 5470 kg 12,059 lb TLS, IVT, 600/65R38, 540/65R24, shipping fuel, front weight support: 6091 kg 13,428 lb 6100 kg 13,448 lb |

| Maximum ballast level | |

| Maximum permissible weight | 9950 kg 21,936 lb |

Capacities | |

| Crankcase oil volume | 16 L 4.2 U.S. gal. |

| Fuel tank | 195 L 51.5 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | 13 L 3.4 U.S. gal. |

| Cooling system | 28 L 7.4 U.S. gal. |

| Transmission-hydraulic system | IVT: 60 L 15.9 U.S. gal. AutoQuad: 53 L 14 U.S. gal. |

Serviceability | |

| Interval for engine oil change | 500 hours |

| Interval for hydraulic/transmission oil change | 1,500 hours |

| Interval for engine coolant change | 6,000 hours |

Loaders | |

| Loader | 620R 640R |

| Lift capacity at full height | 620R: 2577 kg 5861 lb 640R: 2181 kg 4808 lb |

| Maximum lift height | 620R: 4124 mm 162 in. 640R: 4151 mm 163 in. |

| Leveling type | |

Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

Miscellaneous | |

| AutoTrac ready | |

| ISOBUS ready | |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | Germany |

Additional information | |

Offers & Discounts

Accessories & Attachments

Ag Management Solutions

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

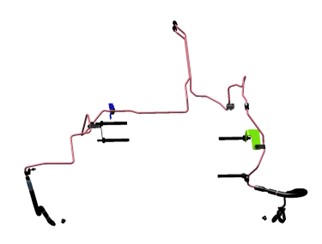

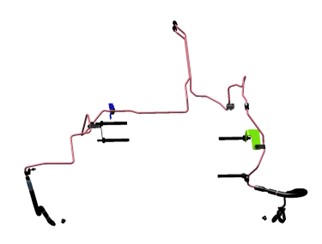

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

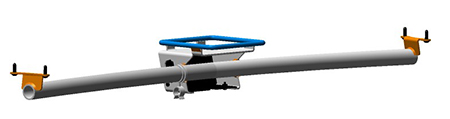

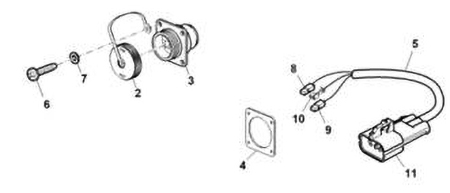

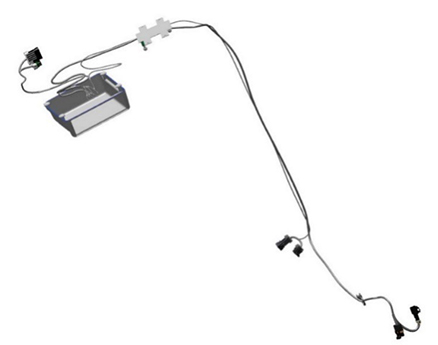

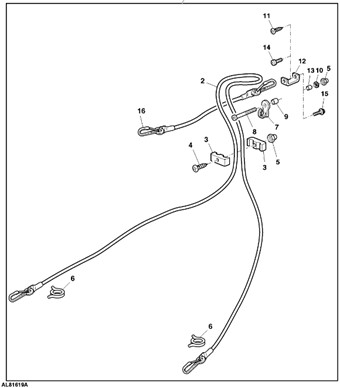

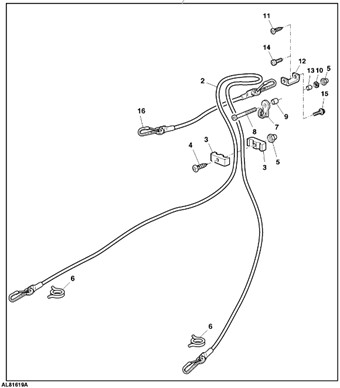

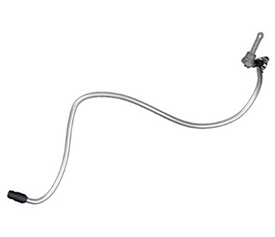

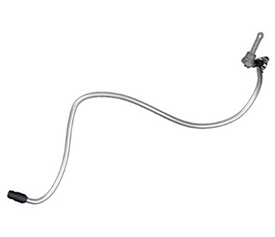

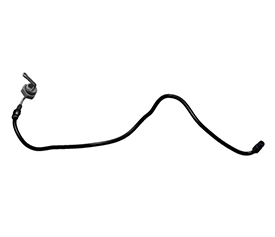

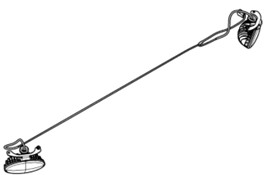

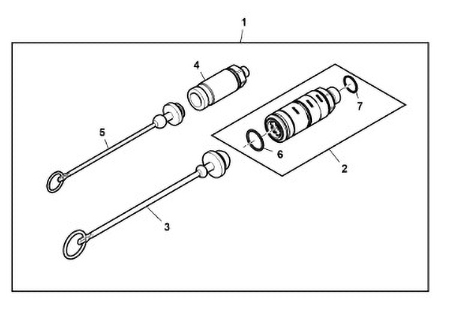

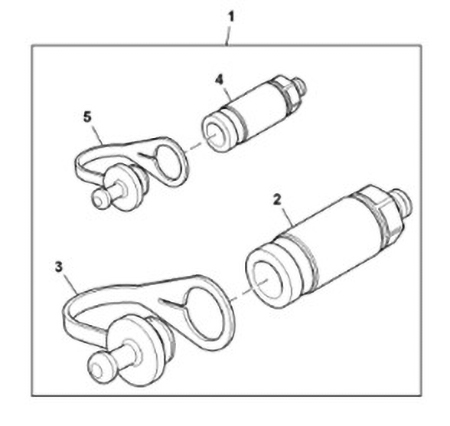

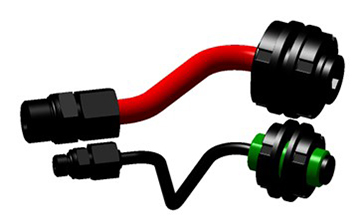

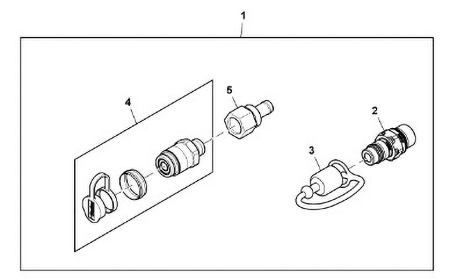

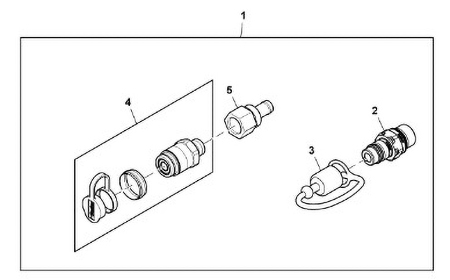

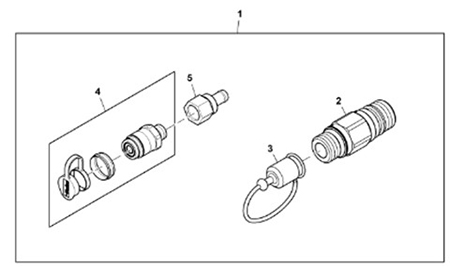

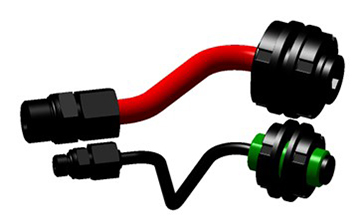

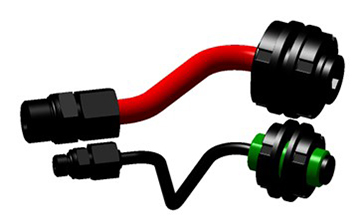

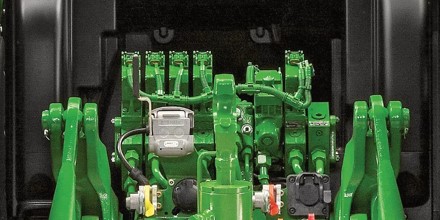

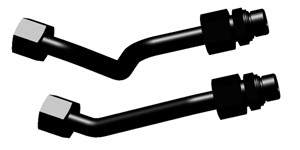

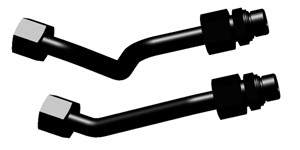

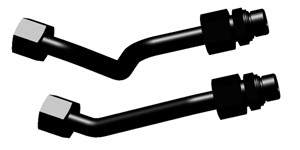

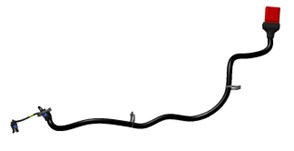

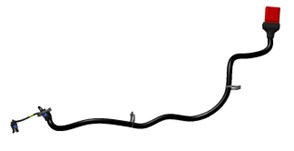

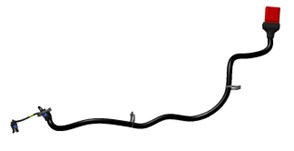

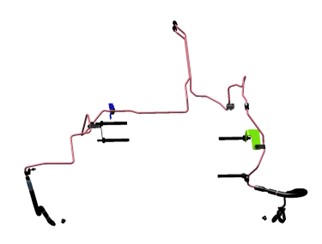

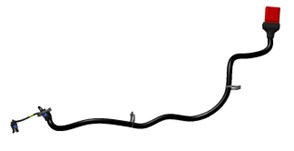

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

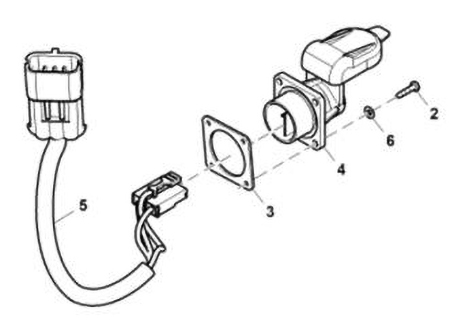

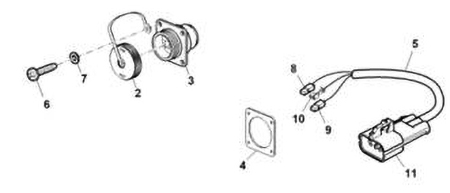

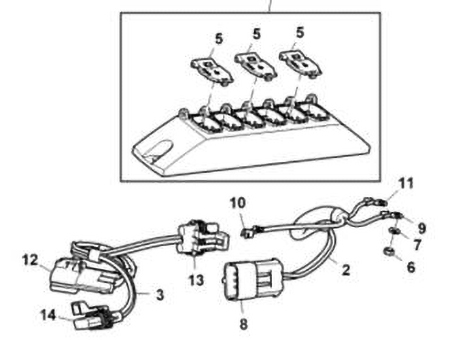

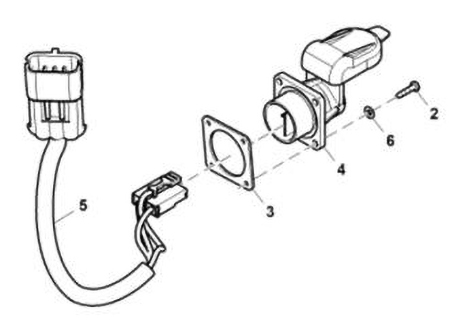

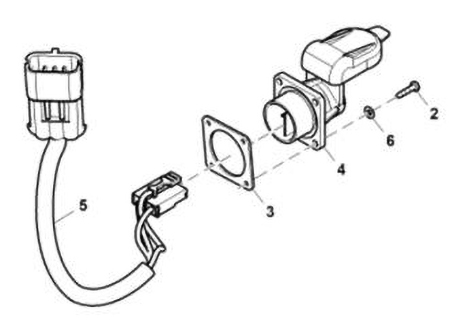

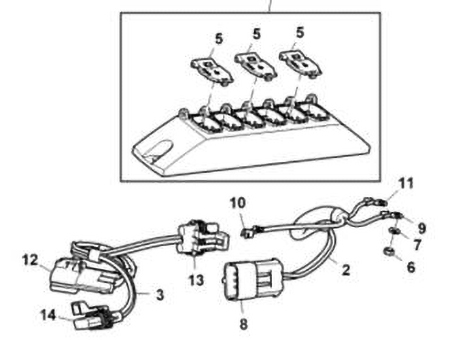

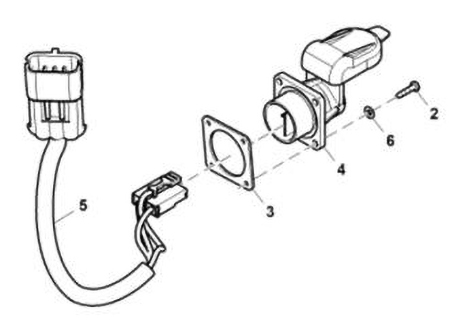

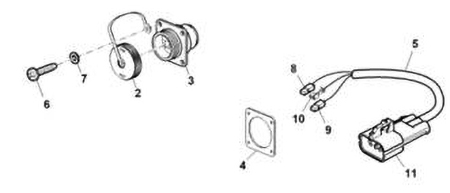

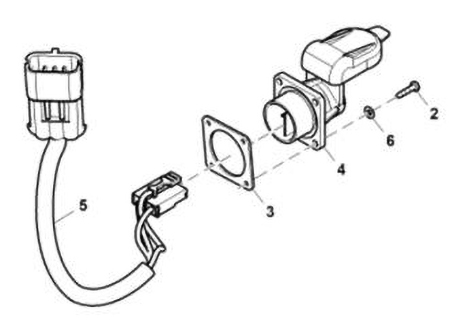

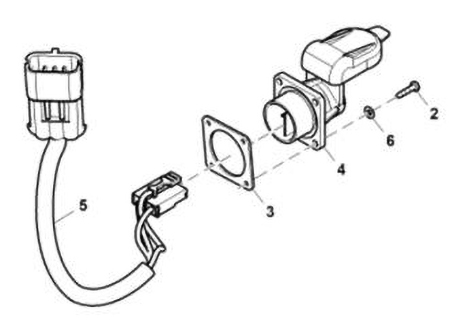

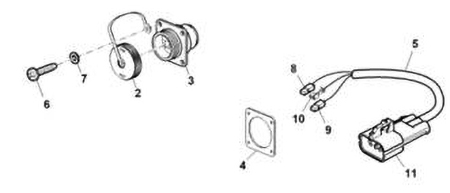

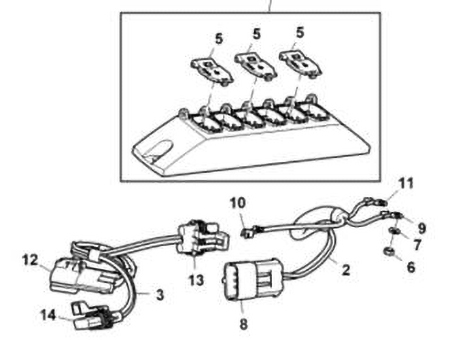

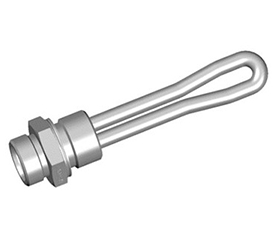

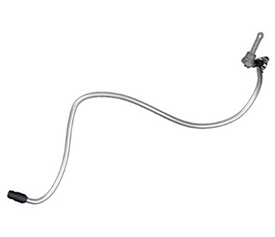

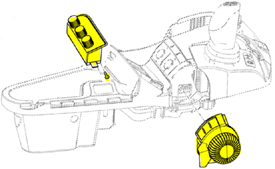

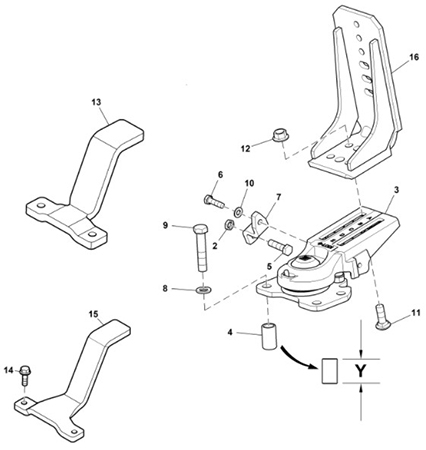

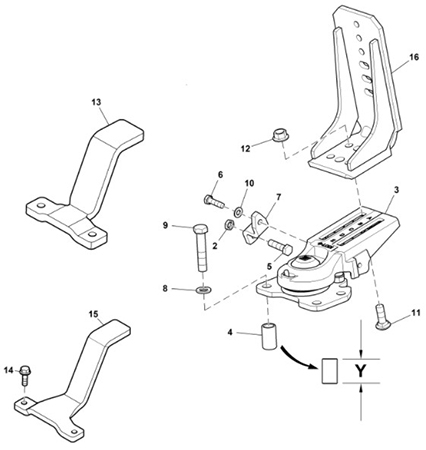

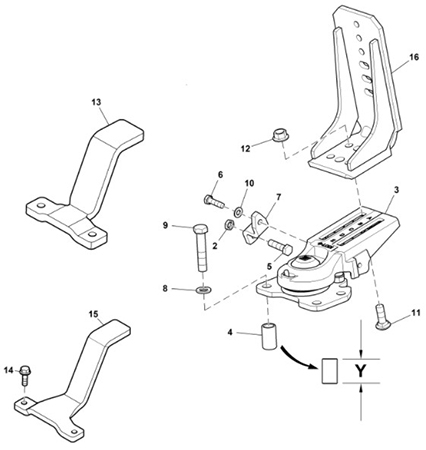

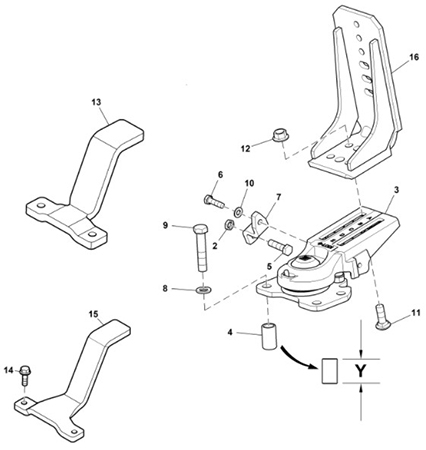

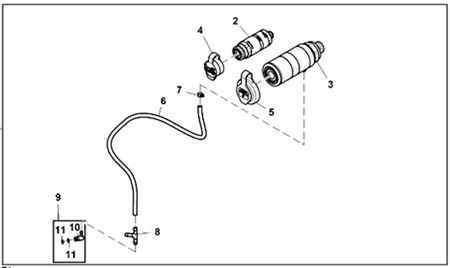

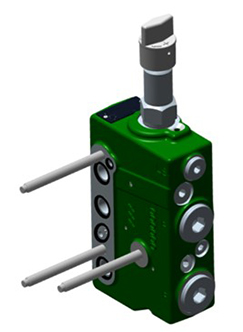

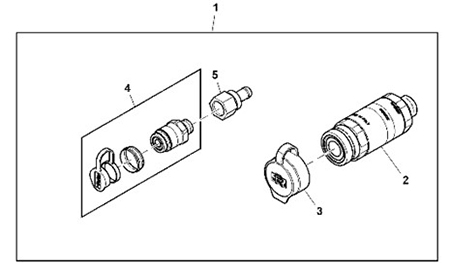

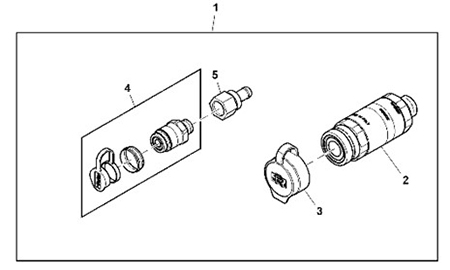

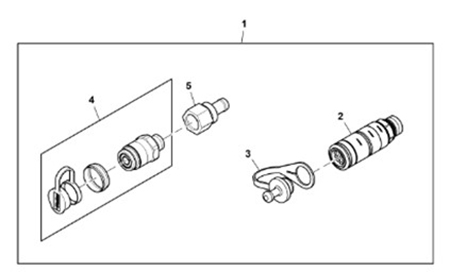

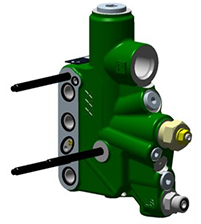

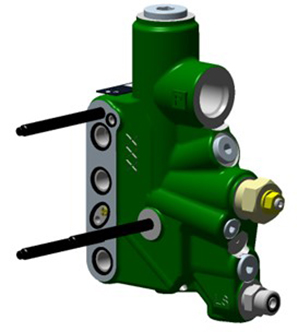

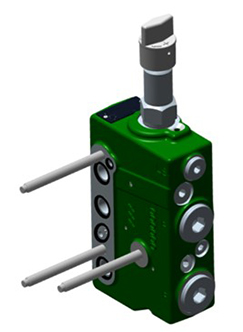

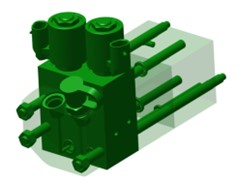

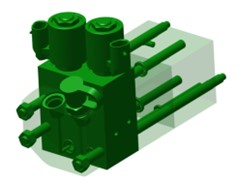

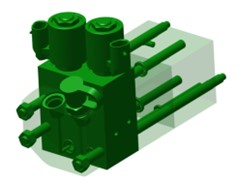

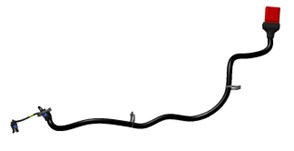

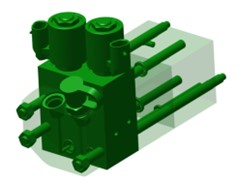

Steering control unit for AutoTrac Ready

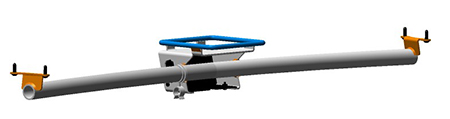

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

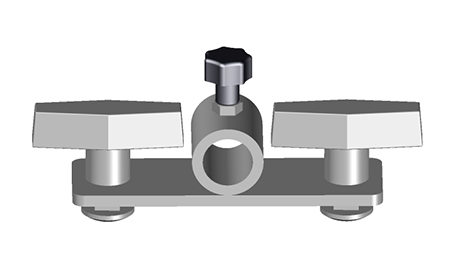

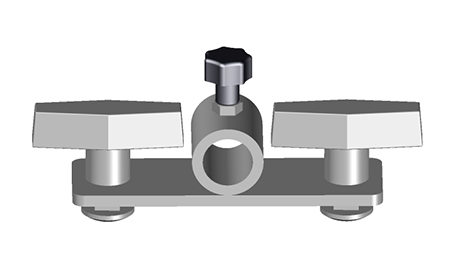

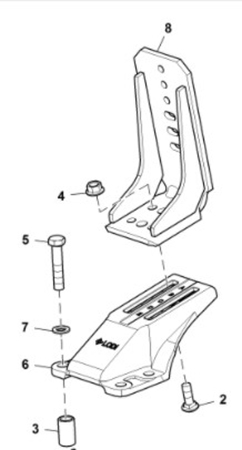

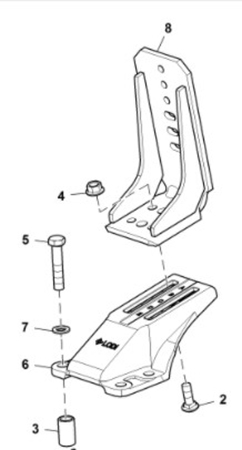

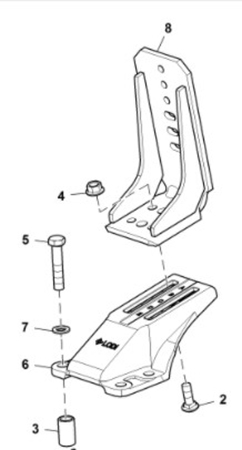

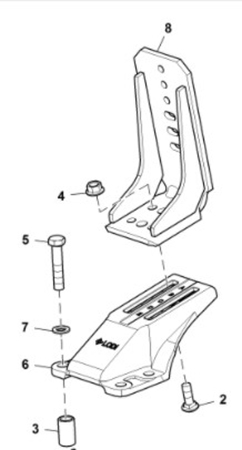

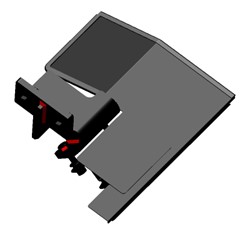

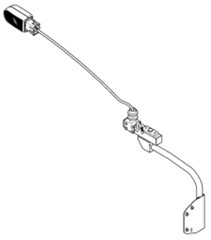

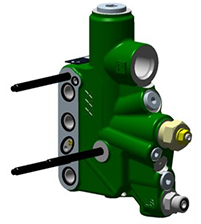

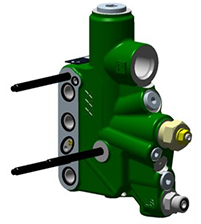

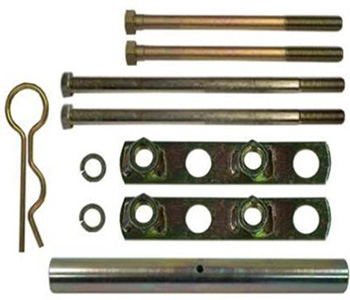

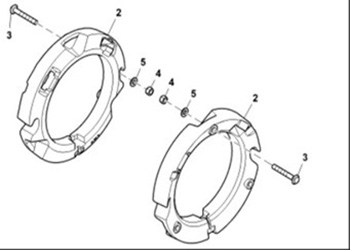

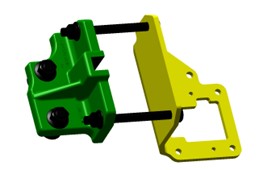

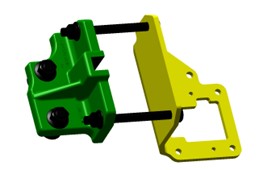

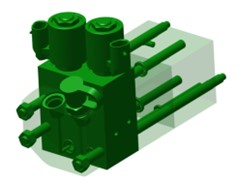

Mounting parts for steering control valve

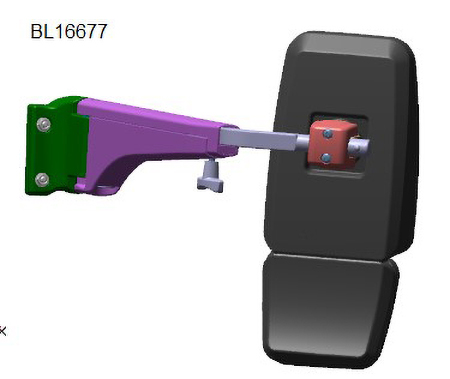

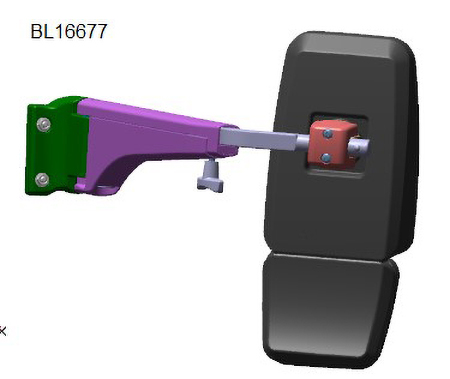

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

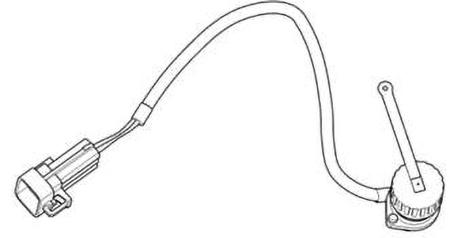

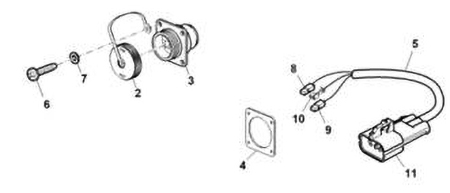

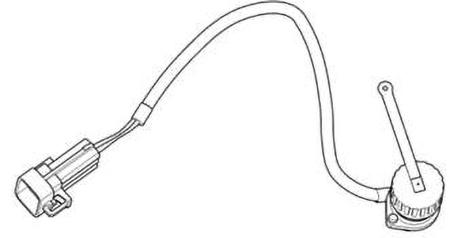

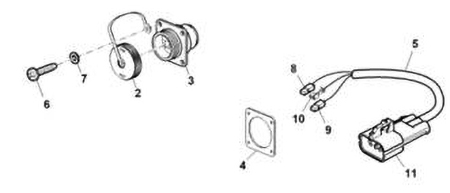

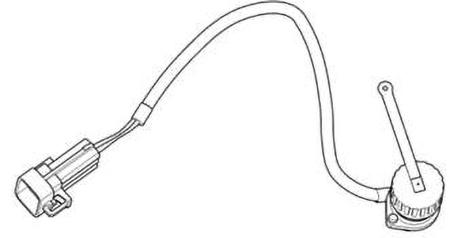

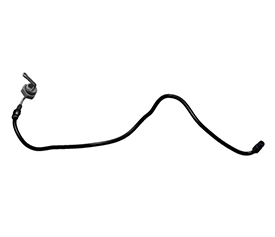

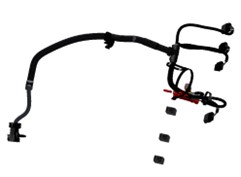

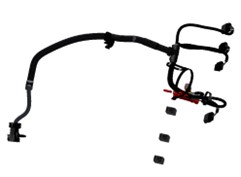

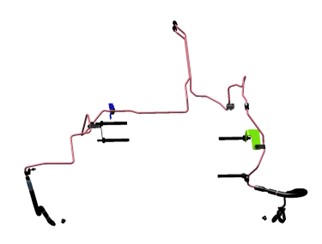

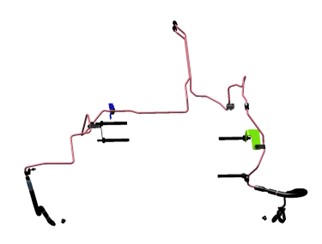

Wiring harness for AutoTrac Ready

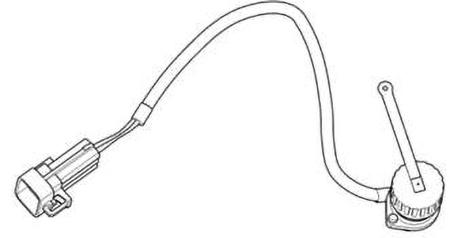

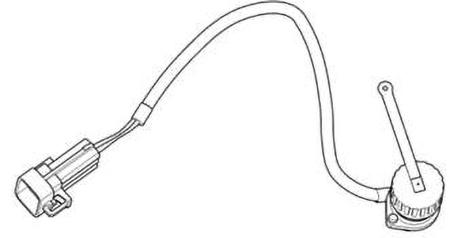

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

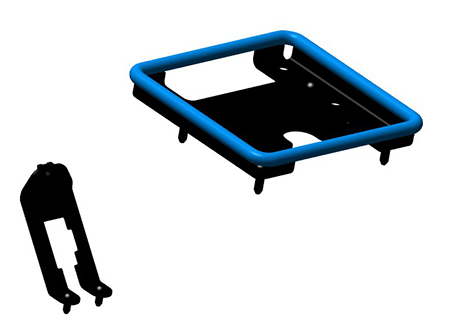

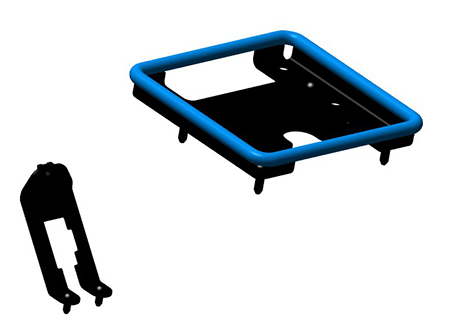

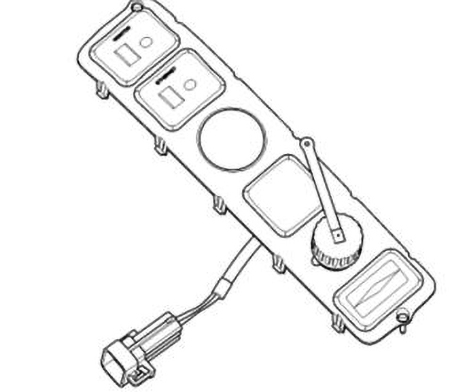

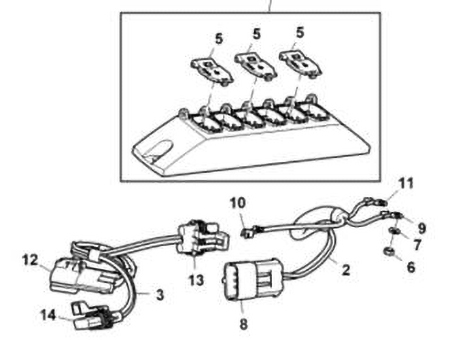

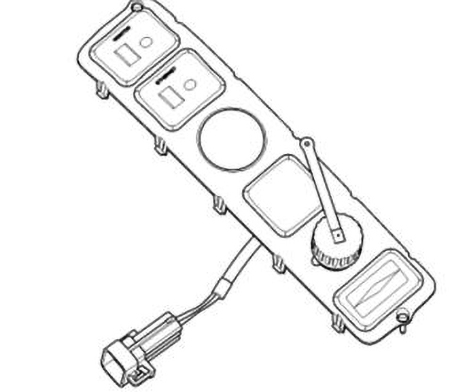

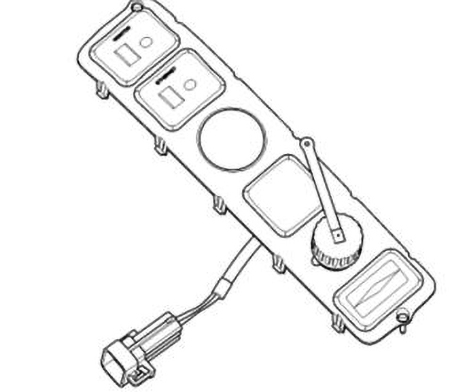

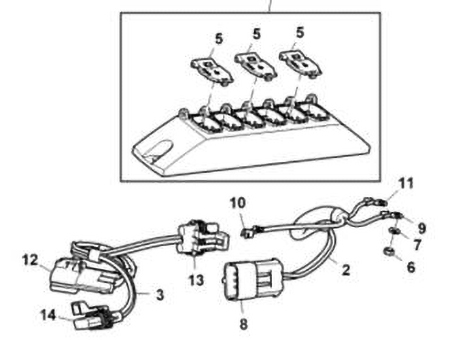

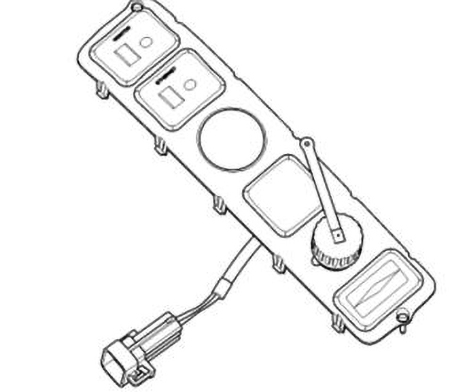

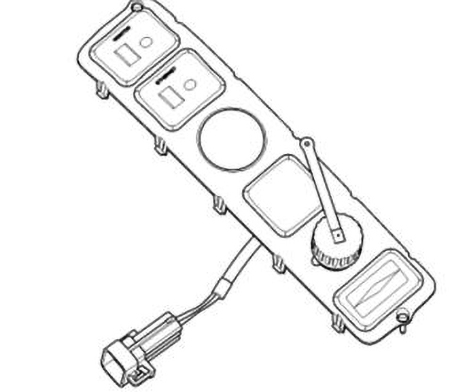

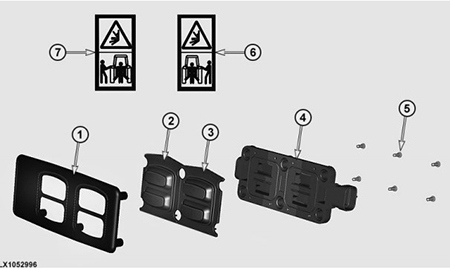

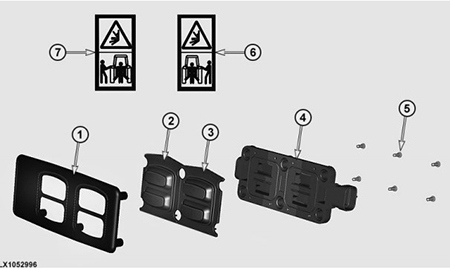

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

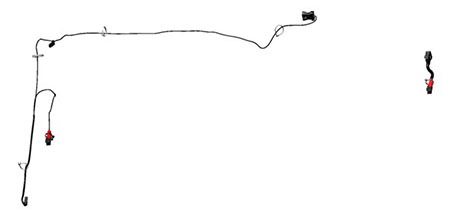

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

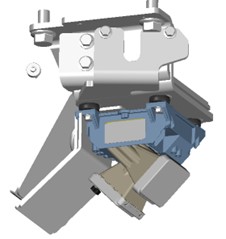

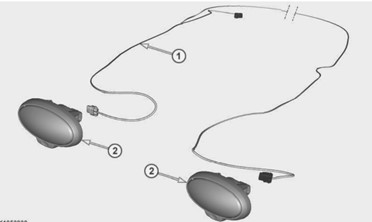

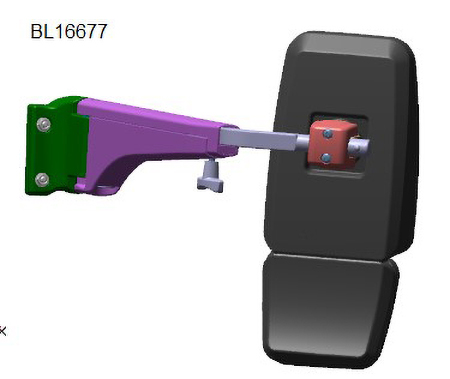

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |

Wiring harness for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16737 |

MHM1893 |

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready |

X |

X |

X |

--- |

1757 |

BL16738 |

MHM1893 |

Wiring harness for GreenStar Ready |

X |

X |

X |

--- |

1757 |

BL16706 |

MHM1893 |

Wiring harness with power socket for ISOBUS/GreenStar Ready or AutoTrac Ready |

X |

X |

X |

--- |

A183 |

BL16771 |

MHM1934 |

JDLink mounting parts |

X |

X |

X |

X |

1757 |

BL16747 |

MHM1893, MHM1927 |

GreenStar Ready kit for panorama roof |

X |

X |

X |

X |

1757 |

BL16746 |

MHM1893, MHM1927 |

GreenStar Ready kit for standard roof |

X |

X |

X |

X |

8216 |

BL16796 |

|

Software for iTEC control |

X |

X |

X |

X |

8216 |

BL16799 |

MHM1953 |

Wiring harness for iTEC control |

X |

X |

X |

X |

Overview

With JDLink operators can remotely access critical machine data and manage their fleet in one place. JDLink is the telematics system from John Deere that connects all machines in the field with office and mobile devices. The technology is based on a Modular Telematics Gateway (MTG) that collects and transmits data via a cellular network using selective data points in near-real time.

Benefits

With JDLink, operators can:

- Remotely view information from a computer, phone, or tablet.

- Access machine data such as engine hours, wheel slip and fuel level.

- Track machine location and history.

- Set up and manage geofence and curfews.

- Set up Manage maintenance plans and alerts.

- Optimization of overall fleet efficiency.

To retrofit JDLink option A183, the following bundles need to be ordered:

- JDLink Mounting Parts BL16771

NOTE: This attachment contains just the mounting parts for JDLink Ready. Please order MTG Control Unit (Part number depends on region) and high-performance antenna MTG (Cellular/GPS) separately.

Code |

Attachment |

Description |

Applicable models |

||||||||||||

BL16771 |

JDLink Mounting Parts |

|

Required components to retrofit JDLink option A183:

BL16771

BL16771

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

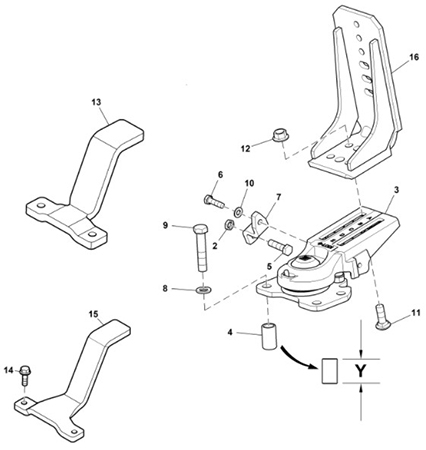

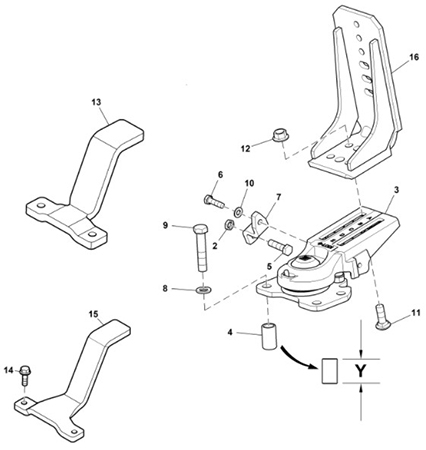

Steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

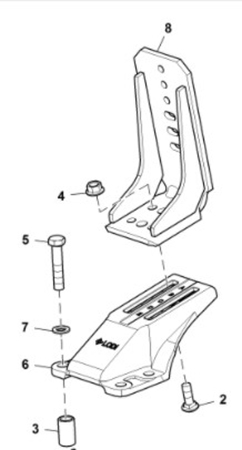

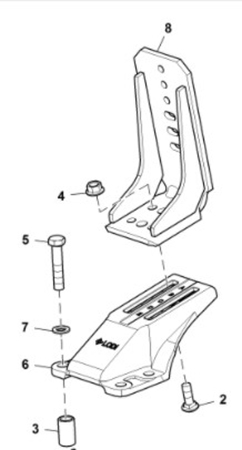

Mounting parts for steering control valve

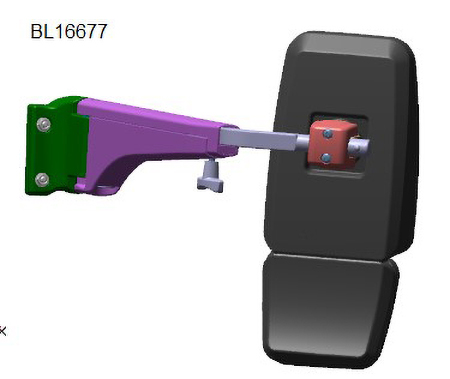

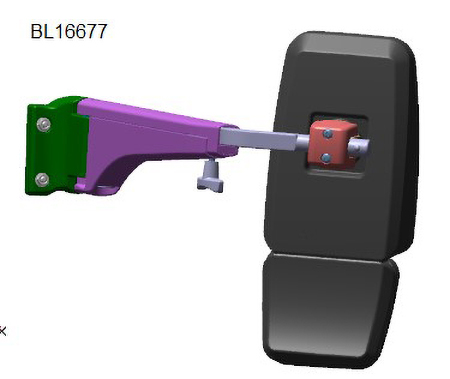

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

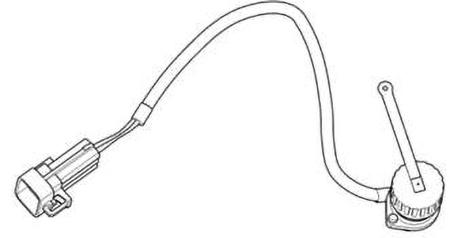

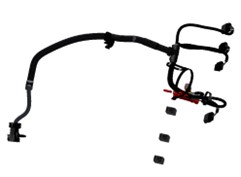

Wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |

Wiring harness for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16737 |

MHM1893 |

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready |

X |

X |

X |

--- |

1757 |

BL16738 |

MHM1893 |

Wiring harness for GreenStar Ready |

X |

X |

X |

--- |

1757 |

BL16706 |

MHM1893 |

Wiring harness with power socket for ISOBUS/GreenStar Ready or AutoTrac Ready |

X |

X |

X |

--- |

A183 |

BL16771 |

MHM1934 |

JDLink mounting parts |

X |

X |

X |

X |

1757 |

BL16747 |

MHM1893, MHM1927 |

GreenStar Ready kit for panorama roof |

X |

X |

X |

X |

1757 |

BL16746 |

MHM1893, MHM1927 |

GreenStar Ready kit for standard roof |

X |

X |

X |

X |

8216 |

BL16796 |

|

Software for iTEC control |

X |

X |

X |

X |

8216 |

BL16799 |

MHM1953 |

Wiring harness for iTEC control |

X |

X |

X |

X |

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

Steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

Mounting parts for steering control valve

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |

Wiring harness for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16737 |

MHM1893 |

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready |

X |

X |

X |

--- |

1757 |

BL16738 |

MHM1893 |

Wiring harness for GreenStar Ready |

X |

X |

X |

--- |

1757 |

BL16706 |

MHM1893 |

Wiring harness with power socket for ISOBUS/GreenStar Ready or AutoTrac Ready |

X |

X |

X |

--- |

A183 |

BL16771 |

MHM1934 |

JDLink mounting parts |

X |

X |

X |

X |

1757 |

BL16747 |

MHM1893, MHM1927 |

GreenStar Ready kit for panorama roof |

X |

X |

X |

X |

1757 |

BL16746 |

MHM1893, MHM1927 |

GreenStar Ready kit for standard roof |

X |

X |

X |

X |

8216 |

BL16796 |

|

Software for iTEC control |

X |

X |

X |

X |

8216 |

BL16799 |

MHM1953 |

Wiring harness for iTEC control |

X |

X |

X |

X |

StarFire™ receiver mounting bracket for panorama roof

BL16747 Receiver mounting bracket for panorama roof

BL16747 Receiver mounting bracket for panorama roof

This kit includes a bracket for the StarFire receiver. The bracket is mounted in such a way that it does not impair the advantages of the panoramic roof. The bracket and receiver are easily accessible.

StarFire receiver mounting bracket for standard roof

BL16746 GreenStar kit for standard roof

BL16746 GreenStar kit for standard roof

This kit includes a bracket to install a StarFire receiver on a standard roof. The bracket and receiver are easily accessible.

GOC |

Part number |

Installation instruction number |

Description |

1757 |

BL16747 |

MHM1893 |

StarFire receiver mounting bracket for panorama roof |

1757 |

BL16746 |

MHM1893 |

StarFire receiver mounting bracket for standard roof |

StarFire™ receiver mounting bracket for panorama roof

BL16747 Receiver mounting bracket for panorama roof

BL16747 Receiver mounting bracket for panorama roof

This kit includes a bracket for the StarFire receiver. The bracket is mounted in such a way that it does not impair the advantages of the panoramic roof. The bracket and receiver are easily accessible.

StarFire receiver mounting bracket for standard roof

BL16746 GreenStar kit for standard roof

BL16746 GreenStar kit for standard roof

This kit includes a bracket to install a StarFire receiver on a standard roof. The bracket and receiver are easily accessible.

GOC |

Part number |

Installation instruction number |

Description |

1757 |

BL16747 |

MHM1893 |

StarFire receiver mounting bracket for panorama roof |

1757 |

BL16746 |

MHM1893 |

StarFire receiver mounting bracket for standard roof |

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

Steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

Mounting parts for steering control valve

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |

Wiring harness for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16737 |

MHM1893 |

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready |

X |

X |

X |

--- |

1757 |

BL16738 |

MHM1893 |

Wiring harness for GreenStar Ready |

X |

X |

X |

--- |

1757 |

BL16706 |

MHM1893 |

Wiring harness with power socket for ISOBUS/GreenStar Ready or AutoTrac Ready |

X |

X |

X |

--- |

A183 |

BL16771 |

MHM1934 |

JDLink mounting parts |

X |

X |

X |

X |

1757 |

BL16747 |

MHM1893, MHM1927 |

GreenStar Ready kit for panorama roof |

X |

X |

X |

X |

1757 |

BL16746 |

MHM1893, MHM1927 |

GreenStar Ready kit for standard roof |

X |

X |

X |

X |

8216 |

BL16796 |

|

Software for iTEC control |

X |

X |

X |

X |

8216 |

BL16799 |

MHM1953 |

Wiring harness for iTEC control |

X |

X |

X |

X |

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

Steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

Mounting parts for steering control valve

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |

Wiring harness for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16737 |

MHM1893 |

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready |

X |

X |

X |

--- |

1757 |

BL16738 |

MHM1893 |

Wiring harness for GreenStar Ready |

X |

X |

X |

--- |

1757 |

BL16706 |

MHM1893 |

Wiring harness with power socket for ISOBUS/GreenStar Ready or AutoTrac Ready |

X |

X |

X |

--- |

A183 |

BL16771 |

MHM1934 |

JDLink mounting parts |

X |

X |

X |

X |

1757 |

BL16747 |

MHM1893, MHM1927 |

GreenStar Ready kit for panorama roof |

X |

X |

X |

X |

1757 |

BL16746 |

MHM1893, MHM1927 |

GreenStar Ready kit for standard roof |

X |

X |

X |

X |

8216 |

BL16796 |

|

Software for iTEC control |

X |

X |

X |

X |

8216 |

BL16799 |

MHM1953 |

Wiring harness for iTEC control |

X |

X |

X |

X |

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

Steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

Mounting parts for steering control valve

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |

Wiring harness for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16737 |

MHM1893 |

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready |

X |

X |

X |

--- |

1757 |

BL16738 |

MHM1893 |

Wiring harness for GreenStar Ready |

X |

X |

X |

--- |

1757 |

BL16706 |

MHM1893 |

Wiring harness with power socket for ISOBUS/GreenStar Ready or AutoTrac Ready |

X |

X |

X |

--- |

A183 |

BL16771 |

MHM1934 |

JDLink mounting parts |

X |

X |

X |

X |

1757 |

BL16747 |

MHM1893, MHM1927 |

GreenStar Ready kit for panorama roof |

X |

X |

X |

X |

1757 |

BL16746 |

MHM1893, MHM1927 |

GreenStar Ready kit for standard roof |

X |

X |

X |

X |

8216 |

BL16796 |

|

Software for iTEC control |

X |

X |

X |

X |

8216 |

BL16799 |

MHM1953 |

Wiring harness for iTEC control |

X |

X |

X |

X |

Power outlet, C-post, ECE

AL205867 three-pin power outlet socket

AL205867 three-pin power outlet socket

NOTE: Only compatible with Region 1, Region 2, and Region 3 kits.

Power outlet, C-post, SAE

AL205868 three-pin power outlet socket

AL205868 three-pin power outlet socket

NOTE: Only compatible with Region 4 kits.

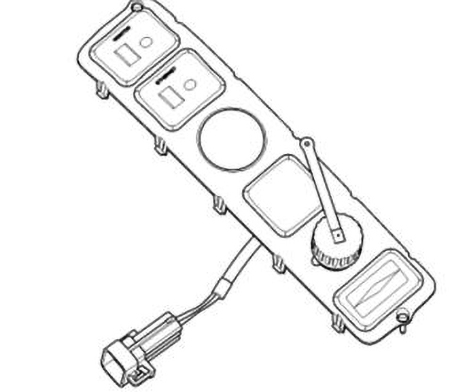

Multi power outlet

BL15392 multi power outlet socket strip

BL15392 multi power outlet socket strip

Multiple socket strap with seven pin signal socket

BL15389 seven-pin signal socket

BL15389 seven-pin signal socket

NOTE: For tractors without CommandARM™.

Please order software AL216202 in addition, requires tractor serial number. See installation instruction for details.

Multiple socket strap with seven-pin signal socket premium plus

BL15391 multiple sockets with integrated seven-pin signal socket premium plus

BL15391 multiple sockets with integrated seven-pin signal socket premium plus

NOTE: CommandARM console (code 2704) required. Also compatible with CommandARM console with CommandPRO™ controls (code 2708). Please order software AL216202 in addition, requires tractor serial number.

See installation instruction for details.

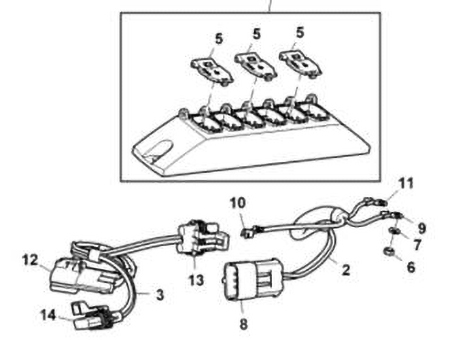

Overview

iTEC Basic (Intelligent Total Equipment Control) increases the productivity of tractors as a powerful headland management system. In row crops as well as in tillage or grassland work, the driver is noticeably relieved by the automation of the work processes when turning at the headland.

This content shows how to retrofit iTEC Basic Option 8216.

Benefits

- Activation and deactivation of the four-wheel drive

- Activation and deactivation of the differential lock

- Activation and deactivation of the rear PTO

- Raise, lower and quick control of the rear hitch

Additional details

To retrofit iTEC Basic Option 8216, the following bundles need to be ordered:

- Software for iTEC

- Wiring Harness for iTEC

Required for iTEC Option 8216 retrofit if the tractor is not equipped with Greenstar or AutoTrac. Requires software AL214978 to be ordered in addition.

Code |

Attachment |

Description |

Applicable models |

|||||

BL116796 |

Software for iTEC |

|

||||||

|

BL16799 |

Wiring Harness for iTEC |

|

BL16738

BL16738

NOTE: This information is intended to show a more complete portfolio of options available for this area of the machine. Check the tables below to verify specific model and configuration compatibility.

Global order codes (GOC) describe features that can only be ordered ex factory. The retrofit of an entire GOC might require several bundles (BL-/AL- numbers). GOCs starting with an “A” are only available as a retrofit solution and not ex factory (for example, A183).

AutoTrac™ automated steering reduces overlap and saves time, fuel, and labor costs, whether you are cultivating, ploughing, seeding, or fertilizing. Overlap is reduced by 90 percent.

Benefits:

- Saving costs of operation

- Higher operator comfort

- Overall improved efficiency

To retrofit AutoTrac Ready, the following attachments must be ordered:

- Steering lines for AutoTrac Ready

- Steering control unit for AutoTrac Ready

- Mounting parts for steering control valve

- GreenStar™ roof kit for standard or panorama roof

- Wiring harness for AutoTrac Ready

- Cab controls for AutoTrac Ready

If the tractor is not equipped with an ISOBUS/GreenStar kit, also order:

- Wiring harness for GreenStar Ready (BL16738)

- Wiring harness for ISOBUS socket (BL16706)

See installation instruction for details. Also see the Precision Ag price list for the StarFire™ receiver, Gen 4 displays and AutoTrac activation.

Steering lines for AutoTrac automated steering

BL16628 steering lines for AutoTrac

BL16628 steering lines for AutoTrac

These steering lines are required to enable automated steering through AutoTrac system.

NOTE: Compatible with front axles with and without TLS™ suspension system.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 150 |

6R 145- 6R 185 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1756 |

BL16628 |

MHM1893 |

Steering lines for AutoTrac automated steering |

X |

--- |

--- |

--- |

1756 |

BL16629 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

X |

--- |

--- |

1756 |

BL16630 |

MHM1893 |

Steering lines for AutoTrac automated steering |

--- |

--- |

X |

--- |

Steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

BL16534 steering control unit for AutoTrac Ready

This attachment includes the required steering control unit for AutoTrac.

Mounting parts for steering control valve

BL16748 mounting parts for steering control

BL16748 mounting parts for steering control

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

BL16739 wiring harness for AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

Cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

BL16737 cab controls for ISOBUS Ready/GreenStar Ready and AutoTrac Ready

These cab controls enable the activation of automated steering through AutoTrac. This kit includes a mounting bracket for a Gen 4 display.

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

BL16738 wiring harness for GreenStar Ready

NOTE: Required for AutoTrac Ready retrofit.

Wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

BL16706 wiring harness with power socket for ISOBUS/AutoTrac Ready

NOTE: Required for AutoTrac Ready retrofit.

JDLink™ system mounting parts

BL16771 JDLink mounting parts

BL16771 JDLink mounting parts

This attachment contains only the mounting parts for JDLink™ Ready.

Order the Modular Telematics Gateway (MTG) control unit separately (part number depends on region).

- Refer to the Precision Ag Price Pages.

Order the high-performance antenna MTG (cellular/GPS) separately (PFA10879).

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

BL16747 ISOBUS and GreenStar Ready kit for panorama roof

This kit includes the StarFire receiver mounting bracket for tractors with a panorama roof.

NOTE: Required for AutoTrac Ready retrofit.

GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

BL16746 GreenStar Ready kit for standard roof

This kit includes the StarFire receiver mounting bracket for tractors with a standard roof.

NOTE: Required for AutoTrac Ready retrofit.

Software for iTEC™ control

iTEC (Intelligent Total Equipment Control) is a high-performance headland management system for improving the productivity of 6 Series Tractors. With this feature, the operator can automate headland sequences.

NOTE: Order software AL214978 in addition. Requires wiring harness for iTEC control.

Wiring harness for iTEC control

NOTE: Requires software for iTEC control.

GOC |

Part number |

Installation instruction number |

Description |

Compatible models |

|||

6R 110- 6R 140 |

6R 145- 6R 165 |

6R 175- 6R 215 |

6R 230-6R 250 |

||||

1758 |

BL16534 |

MHM1893 |

Steering control unit for AutoTrac Ready |

X |

X |

X |

--- |

1758 |

BL16748 |

MHM1893 |

Mounting parts for steering control valve |

X |

--- |

--- |

--- |

1758 |

BL16749 |

MHM1893 |

Mounting parts for steering control valve |

--- |

X |

X |

--- |

1758 |

BL16739 |

MHM1893 |