3046R

Compact Utility Tractor

- AutoConnect™ deck compatible for deck attach/detach in seconds

- Cab or Open Station configuration available

- Standard hydrostatic transmission with Twin Touch™ pedals

Starting At:

$37,808.00

View Product Brochure

Features

3R Open-Operator Station Tractor

3R Open-Operator Station Tractor

The bold styling of the tractor provides an attractive and functional appearance similar to that of the larger agricultural tractors. Benefits of this styling include:

- Easy tractor family identification

- Updated fixed grill and side panel hood design allowing for optimum sealing of the cooling compartment

- Integrated maintenance position on front grill for easy battery access

- Wraparound-style halogen headlights

- Premium integrated automotive style headlight bezels

- Bold graphics allowing for easy tractor family identification

- Aggressively sloped hood design giving a softer, smoother look, and providing improved visibility

- Hybrid exhaust in base for clear operator visibility and safety

The result gives the tractor a distinctive appearance and feel.

NOTE: If tractor is equipped with optional field-installed vertical exhaust, exhaust pipe must be removed before opening and closing the hood of the tractor.

Yanmar 3-Cylinder, TNV Series diesel engine

Yanmar 3-Cylinder, TNV Series diesel engine

The Yanmar 3-cylinder, TNV series diesel engine features a high torque reserve that provides plenty of power under heavy loads.

This engine features lower levels of exhaust emissions and reduced noise levels. The engine meets all current Environmental Protection Agency (EPA) emission requirements for Final Tier 4 emission standards.

The 1.642-L (100.2-cu in.) displacement, naturally aspirated, 3TNV88C-MJTV Yanmar diesel engine provides 23.7 kW (31.8 hp) to the 3033R Tractor.

Model |

Number of |

Engine |

Rated rpm |

Gross engine |

Gross engine ps* |

PTO power* |

3033R |

3 |

1.642 L (100.2 cu in.) |

2600 |

23.7 kW (31.8 hp) |

32.2 |

17.2 kW (23 hp) |

*Engine hp (kW), gross SAE J1995: 31.8 (23.7) at 2600 rpm, PS

Displacement, cu in. (L):100.2 (1.642)

3039R

The 1.568-L (95.7-cu in.), turbocharged, 3TNV86CT-MJTV Yanmar diesel engine provides 28.5 kW (38.2 hp) to the 3039R Tractor.

Model |

Number of |

Engine |

Rated rpm |

Gross engine |

Gross engine ps* |

PTO power* |

3039R |

3 |

1.568 L (95.7 cu in.) |

2600 |

28.5 kW (38.2 hp) |

38.7 |

22.2 kW (29.8 hp) |

*Engine hp (kW), gross SAE J1995: 38.2 (28.5) at 2600 rpm, PS

Displacement, cu in. (L): 95.7 (1.568)

3046R

The 1.568-L (95.7-cu in.), turbocharged, intercooled 3TNV86CHT-MJTV Yanmar diesel engine provides 33.3 kW (44.7 hp) to the 3046R Tractor.

Model |

Number of |

Engine |

Rated rpm |

Gross engine power* |

Gross engine ps* |

PTO power* |

3046R |

3 |

1.568 L (95.7 cu in.) |

2600 |

33.3 kW (44.7 hp) |

45.3 |

25.3 kW (33.9 hp) |

*Engine hp (kW), gross SAE J1995: 44.7 (33.3) at 2600 rpm, PS

Displacement, cu in. (L): 95.7 (1.568)

The engine uses latest technologies to optimize fuel economy, improve control and accuracy, and reduces environmental impact.

The common rail system (CRS) optimizes fuel economy and reduces operating costs compared to engines not using CRS technology. High pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and lower cost of operation.

The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions.

The new engine comes with an after treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC).

After many hours of use, the exhaust filter may require an ash removal service.

DPF cleaning

Depending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

- A prescribed time-based estimation of needed filter cleaning

- DOC/DPF pressure sensors

- A particulate matter buildup estimation based on load conditions

Once one of the three conditions has been met, filter cleaning will occur.

There are three different types of filter cleaning processes:

- Passive filter cleaning

- Active filter cleaning

- Parked filter cleaning

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Active filter cleaning

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner.

To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize PM.

It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF.

Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Parked filter cleaning

In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process.

The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details.

This system constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

NOTE: When the tractor is in a filter cleaning process at low speed or while parked and running, the exhaust will be routed through the vertical exhaust outlet. In all other cases, the exhaust will be routed through the downward exhaust outlet. This ensures minimal heat impact to operator.

Key features of the engine are:

- Economical cast-in-block cylinder design for good cooling and long life

- Direct fuel injection

- Improves starting

- Injects fuel directly on top of pistons for more efficient combustion

- Develops more horsepower per gallon of fuel than indirect injection engines

- Aluminum alloy pistons with built-in steel struts are lightweight to reduce connecting rod-bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, which reduces blow-by and noise from piston slap

- Top rings are higher on the piston and a thinner head gasket is used to greatly reduce the volume of unburned waste gases and increase combustion efficiency

- Timing gears and injector drive gears have a helical profile to reduce engine noise

- Auto-bleed fuel system

- There is no need to prime the system if the tractor runs out of fuel

- The system will self-prime the injection pump, lines and injectors, providing fast fuel recovery for easier starting

- Key start and shutoff eliminates fuel shutoff knob

- Electric solenoid shuts fuel supply off immediately when key is turned off

- Fuel filter with replaceable element

- Water separator

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Sealed radiator compartment keeps trash and debris on outside of hood

Dry-type air cleaner

Dry-type air cleaner

- Dry-type air cleaner with safety element and electronic air service indicator

- Electronic air restriction indicator alerts operator when air filter servicing is required

- Dual element design for added engine protection

- Easy to service

- Hybrid exhaust

- Discharges fumes away from the operator and reduces noise from engine

- Improves operator visibility

- Optional vertical exhaust kit is available

- In normal operations, the exhaust goes through the downward exhaust outlet

- In park regeneration process, the exhaust will go through the upward exhaust outlet

Yanmar is a trademark of Yanmar Company Limited.

The 3R Series Tractor is available with an exclusive three-range electronic hydrostatic (eHydro) transmission.

- Fluid under pressure transmits engine power to the drive wheels through a pump and motor

- Provides high torque for start-up

- Reduces powertrain shock loads

Sauer-Danfoss® supplies both the pump and motor. This ensures that the components are matched to each other, providing maximum efficiency.

The electronic hydrostatic transmission is ideally suited for jobs where productivity is a must, such as loader or mower applications.

Twin Touch™ foot controls allow selecting both direction of travel and speed with a touch of the toe.

Key features of the eHydro transmission are:

- Infinite ground speeds, even at full throttle, allow the operator to match the speed of the tractor to the job

- No clutching for fast and easy direction changes

- Twin Touch foot pedals for quick and easy forward/reverse operation

- Cruise control is base equipment

- Cruise-control switch is located on the right-hand console for easy access

- Cruise control is electronically engaged and disengaged and allows for more precise setting of speed

Sauer-Danfoss eHydro transmission is used for reliable operation. Durability features include:

1) Large forged trunnion shaft with larger support bearings to reduce vibration and noise.

2) Center section made from durable cast aluminum, which is 10 percent stronger.

3) Transmission oil cooler cools transmission oil for longer transmission life.

Safety features of the eHydro transmission include:

- The tractor starts with one or both foot pedals depressed, but it does not move until both pedals first come to neutral.

- The tractor comes to a stop if the operator leaves the seat, but the engine does not shut off unless the power take-off (PTO) is also running.

Key John Deere advantage

Twin Touch foot controls

Twin Touch foot controls

John Deere's Twin Touch foot controls offer several key advantages over competitive hydrostatic transmission (HST) tractor models.

Key advantages over competitive HST tractor models:

- Some competitive hydrostatic tractors use a treadle pedal (toe-heel) design foot control for operation

- Requires the operator to use both toe and heel to change direction, resulting in increased operator fatigue.

Integrated eHydro features

The eHydro convenience controls have been integrated into a single module. Combining features such as SpeedMatch™ cruise control, LoadMatch™ switch, MotionMatch, eThrottle, and automotive style cruise control pulls the maximum efficiency out of the eHydro transmission tractors. All these features are standard on the 3R models and deliver an easier and more comfortable user experience.

eHydro convenience control module

eHydro convenience control module

eThrottle

eThrottle indicator

eThrottle indicator

The 3R Series Tractors come equipped with the eThrottle function. This feature is designed make the tractor quieter and use less fuel. With the simple push of a button, the engine speed is linked to the pedal position. The operator can keep the throttle essentially all the way in the low position. The engine rpms, as well as the tractor speed, increase together with the pedal position. This provides the operator with comfort and convenience as well as fuel economy.

Automotive-style cruise control

Cruise control indicator

Cruise control indicator

An automotive-style cruise control is standard equipment on the 3R Series Tractors. Cruise control is electronically engaged and disengaged and is located on the right-hand operator console.

- Maintains desired forward speed without pressure on the foot pedal

- When activated, operator can set cruise speed

- Use the SET/- button to set cruise speed, or to decrease cruise/max speed

- Use the RES/+ button to set cruise speed, or to increase cruise/max speed

- A speed sensor also allows the tractor to maintain preset speed driving up and down hills

- To disengage the cruise control, either:

- Apply pressure to the brakes

- Disengage cruise control button

- Briefly depress the reverse travel pedal

LoadMatch power management system

LoadMatch indicator

LoadMatch indicator

LoadMatch is an industry exclusive and a standard feature on the 3R Series Tractors.

If torque requirements increase significantly, the transmission will reduce the tractor's drive speed to compensate for the increased load on the transmission, maximizing torque to drive wheels and minimize stalls.

Controls automatically adjust LoadMatch compensation depending on the tractor’s application. PTO applications require less engine speed fluctuation, therefore adjusts the amount of droop depending on PTO speed. This adjustment increases efficiency and optimizes engine speed and torque output based on tractor application.

While typically left on, LoadMatch can be turned off with the right-hand console controls.

MotionMatch

MotionMatch, standard on the 3R Series Tractors, is located on the right-hand console. It offers seven settings for adjusting the rollout or decelerate when the pedal is released.

MotionMatch indicator

MotionMatch indicator

Longer accelerate and decelerate distances.

MotionMatch indicator

MotionMatch indicator

Shorter accelerate and decelerate distances.

SpeedMatch

SpeedMatch indicator

SpeedMatch indicator

SpeedMatch, standard on the 3R Series Tractors, further enhances the eHydro cruise control functions by allowing the operator to preset maximum speed. Once this feature is engaged, the operator must stroke the travel pedal fully to meet the operator preset speed. This function improves accuracy and safety, particularly at lower travel speed applications.

Rotary tilling or spraying applications are examples of where SpeedMatch can be applied. SpeedMatch will work in both the forward and reverse set speeds.

NOTE: Automotive-style cruise control and SpeedMatch can be used in conjunction with LoadMatch to maximize productivity.

Sauer-Danfoss is a trademark of Sauer-Danfoss, Inc.

The PowrReverser transmission, available on 3033R and 3039R Tractors, offers a hydraulically shifted forward-to-reverse transmission. This allows for clutchless shuttle shifting between forward and reverse with one lever for quick and easy direction change.

- The PowrReverser transmission does not require the operator to use the clutch to shift between forward and reverse.

The 12x12 PowrReverser transmission's hydraulically actuated wet clutch takes the place of the dry-type traction clutch. Two multi-disk clutch packs (one forward and one reverse) are hydraulically actuated when the directional (reverser) lever is placed in either the forward or reverse position.

Each clutch pack consists of three large, 13-cm (5-in.) diameter clutch disks that are oil-cooled, allowing excellent heat dissipation and extended clutch life.

Forward/reverse clutches

Forward/reverse clutches

- Clutch A is used for the forward operation of the tractor

- Clutch B is used for the reverse operation of the tractor

Key features of the PowrReverser transmission are:

-

12 forward and 12 reverse speeds

- Reverser lever, located on the left side on the instrument console, allows operator to make direction changes without clutching

- Fast shuttle shift for improved loader operation

Helical-cut gears

Helical-cut gears

- Dual-cone synchronizers allow for synchronized shifts between gears for on-the-go shifting with use of the clutch

- Helical-cut gears for quiet operation

- Well-spaced speeds for turf, loader, and transport work

- Neutral-start switch prevents tractor from starting when transmission (main range) is not in neutral

- Dual wet-disk clutches provide long clutch life

- Shifts between ranges are not synchronized

NOTE: 3R Tractors with PowrReverser are not compatible with mid PTO. They are not compatible from the factory or field installed.

3R operator's station

3R operator's station

The operator's station is designed for easy entry to/exit from the tractor.

Conveniently placed pedals, as well as repositioned operator controls, provide for a clean and flat platform design, giving the operator plenty of legroom.

- Hood and fenders are made from composite polymer material designed to eliminate the possibility of rusting and resistance to dents that can occur with metal hoods and fenders. This material provides a high-luster appearance with excellent resilience and resistance to fading from sunlight.

- Easy-fold rollover protective structure (ROPS) has built-in, rattle-reducing isolator.

Safety certified folding ROPS

Safety certified folding ROPS

Safety certified folding ROPS

Safety certified folding ROPS

Key features of the operator's station include:

- Large grab handles on each fender make getting on and off the tractor easy

- Tilt steering wheel design in base equipment. The tilt wheel:

- Allows the operator to adjust the steering wheel to the most comfortable position

- Provides additional clearance for the operator to enter and exit the tractor

- Provides easy return to the fully raised position

- Provides plenty of room for comfortable operation

- Updated M-B-R power take-off (PTO) selector lever is standard equipment and allows independent control of the mid and rear PTO

- Mid PTO cannot be ordered as a factory-installed option on standard cab or snow cab tractors and must be ordered separately as a field-installed option.

- Controls are shape and color coded for easier identification and operation

- Easy-fold ROPS include a built-in isolator for rattle free operation

- A left-side step is in base equipment to enhance access to the operator’s station

- Foot platform is rubber mounted and incorporates a runner mat for operator comfort

- PowrReverser™ models have both hand and foot throttle controls

- Throttle controls are especially useful when using a loader

3R ComfortGard cab

3R ComfortGard cab

John Deere ComfortGard cab tractors are some of the most comfortable, quiet, and easy-to-use cab tractors available anywhere. This premium solution was developed using extensive customer research and validation tools, and some of the most advanced design techniques available.

The following ComfortGard cab tractor models are available:

- 3033R Tractor with hydrostatic transmission (HST)

- 3039R Tractor with HST

- 3046R Tractor with HST

Cab tractors are designed for those operators who demand superior performance.

- Large-property owners

- Commercial operators

- Governmental agencies

- Farmers

Whether doing loader work, front implement work (such as snow removal), mowing, tilling, rotary cutting, or light hay work, the cab tractors have the versatility and muscle to get the job done, all while protecting the operator from the elements.

Design

State-of-the-art design

State-of-the-art design

State-of-the-art design

State-of-the-art design

- Designed by John Deere and built at the John Deere factory in Ramos, Mexico

- Certified to the highest safety standards in the industry

- Fingertip controls and an automotive-like fit and finish

Operators are sure to appreciate what this cab has to offer — beginning with an isolated cab. These cabs are designed with robust mounting points integrated into the rollover protective structure (ROPS) with a unique offset mounting design that provides an ultra-quiet ride.

The four-post ROPS design, carefully laid-out interior, and fuel tank located under the left rear side of the operator's platform provide a full 360 degrees of visibility.

- Operators enjoy a commanding view no matter what task is being performed.

- The raised header bar design allows operators — whether short or tall — to see the loader bucket or pallet forks through virtually the full range of operation.

- Operator fatigue caused by awkward bending is reduced, leading to increased overall productivity.

- The slow-moving vehicle (SMV) sign can be easily removed and stored in the operator's manual holder to provide a clear and unobstructed view for attaching to implements and doing field work.

- The ample headroom and curved glass on all four sides provide a spacious interior and give operators the feel of a large tractor cab.

Operators are well-protected from the elements with a high-performance climate-control system providing heating and air conditioning.

- The climate-controlled cab makes any task more enjoyable whether on a frigid winter day or a hot summer day.

- The cab is completely sealed and pressurized to further protect the operator from the elements.

- A standard high-efficiency clean-air filter keeps even the smallest dust and allergen particles out.

Cab comfort features

Superior operator comfort and visibility

Superior operator comfort and visibility

Optional radio kit

Optional radio kit

Several features are integrated into the design of the cab that deliver superior operator comfort and visibility. These features include:

- Ultra-quiet interior

- Four-post ROPS with curved glass for 360-degree visibility and spacious interior

- Improved climate-control system for maximum operator comfort

- Raised header bar for maximum loader visibility

- Right-hand control center with the most frequently used controls at the operator's fingertips

- Left-hand automotive-style park brake

- Dash-mounted four-wheel drive (4WD) engagement, no awkward bending

- Tilt steering

- Improved shift range linkage for ease in operation

- Flat unobstructed foot platform

- Deluxe cloth seat with a retractable seat belt and armrests for excellent back support

- Factory-installed deluxe air-ride seat with an adjustable backrest and adjustable armrests (available on the 3039R and 3046R)

- Inside rearview mirror for rear visibility

- Optional dual exterior rearview mirrors for added rear visibility

- Ergonomically placed integrated loader joystick control for maximum comfort during operation

- Interior dome light with on, door, and off positions for illumination in low-light conditions

- Optional factory or field-installed Jensen® stereo with AM/FM, weatherband, and powered USB port

- SiriusXM® satellite radio ready and iPod® mobile digital device ready

- SWJHD1630 stereo can be ordered separately through Parts

- Standard sun visor to block unwanted sunlight

- Creature comforts like:

- Dual cup holders

- 12-V power supply

- Cell phone storage

- Hitch pin storage

- Miscellaneous storage

- Operator's manual holder

- Integrated handle providing support for ingress and egress

- Left-side step for convenient ingress and egress

Cab operating features

Right-hand control panel

Right-hand control panel

Side-post mounting bosses

Side-post mounting bosses

Installing rear window removable plug

Installing rear window removable plug

Rear window removable plug installed

Rear window removable plug installed

- Pre-wired for optional accessories like a radio, horn, rear work lights, electric hydraulic diverter, rear wiper/washer, beacon light, and 12-V outlet

- Integrated warning lights/turn signals and taillights, protected from trees and branches

- Integrated roof-mounted antenna, protected from potential damage from trees and branches

- Dual roof-mounted forward work lights for optimum forward visibility at night

- Standard two-speed front windshield wiper to keep the front glass clear

- Optional rear wiper/washer to keep the rear glass clear

- Optional front fenders to protect the front cab glass from mud and debris

- Optional rear fender extensions to help protect doors from mud and debris

- High-impact polymer fenders, dent resistant and painted to an automotive-like finish

- Rear glass that swings out 70 degrees for ventilation or access to the optional iMatch™ hitch

- Easy access to route and mount a controller or monitor through the rear window removable plug and mounting bosses on the side post

- Large, 48.6-L (12.8-gal.) fuel tank for longer operation without re-fueling

- Left rear fender fuel fill with large opening for easy re-fueling

- Fuel tank located under the left side of the operator's station for maximum rear visibility

Cab safety features

-

ROPS — Certified to the highest industry standards for maximum operator protection

-

Operator presence system

-

Engine shuts down if the operator leaves the seat when the transmission, mid, or rear PTO is engaged

-

Tractor must be in neutral and the park brake fully set for stationary PTO work

-

Right-side emergency exit

-

Tempered safety glass in case of breakage

-

Roof-mounted warning lights/turn signals for road transport — two front and two rear

-

Two fender-mounted taillights

-

Easily remove the slow-moving vehicle sign and store it in the operator's manual holder

Deluxe cloth seat

A deluxe cloth seat with retractable seat belt is in base cab equipment.

-

An ergonomically sculpted seat cushion, an adjustable scissor-link suspension, and seat armrests are combined to provide excellent operator comfort and support.

-

The scissor-link suspension can be adjusted for the operator's height and weight.

-

The operator weight adjustment adjusts to the operator's weight (52 kg to 125 kg [115 lb to 275 lb]).

-

Using a lever located under the seat, the seat is adjustable fore and aft for operator height.

-

Retractable seat belts prevent belts from becoming tangled in the seat suspension and controls.

-

Optional air-suspension seat is available.

Optional air-suspension seat

Air-suspension seat

Air-suspension seat

Two air-ride seat options are possible in 3R cab models. Both utilize the same suspension, which is designed to provide an air cushion for vertical-seat travel. This provides maximum operator comfort in any terrain. The two options are:

1. The optional factory-installed air-ride seat with a deluxe cloth two-piece seat with adjustable backrest and integrated armrests (for the 3039R and 3046R only).

Seat features:

- Push the button at the base of the seat to pump up the seat. Pull the button to deflate the seat.

- The seat slides fore/aft with a lever on the right-hand side of the seat.

- The seat back reclines with a lever in the lower left corner of seat cushion.

- Upper backrest extension available as a field installed option.

2. The optional field-installed air suspension kit that requires the existing standard seat to be re-used when installed.

NOTE: The deluxe two-piece seat top can be ordered through Parts for customers who desire it.

Key benefits include:

- Maximum ride comfort and quality, thus minimizing operator fatigue

- Dampens lower frequency vibration better than mechanical suspensions

- Operator weight capacity of 330 lb

- Enhanced appearance with the close-out boot

Lighting equipment

The base lighting package for cab tractors includes:

- Two wide-angle halogen headlights

- Two roof-mounted, adjustable halogen forward work lights, illuminating the work area in nighttime or low-light conditions

- Two front and two rear amber turn signals/warning lights integrated into the cab roof

- Two taillights integrated into the fenders

- Three-position (on/off/auto) interior dome light

Optional lighting

Optional lighting

Optional lighting

Optional lighting includes:

-

Dual roof-mounted adjustable rear work lights

-

Rotating beacon light

Jensen is a trademark of ASA Electronics Corporation. iPod is a trademark of Apple Inc. SiriusXM is a trademark of Sirius XM Radio Inc.

Specs & Compare

Key Specs | 3046R Current Model |

| Engine power (gross) | SAE J1995 rated power: 33.3 kW 44.7 hp 45.3 PS at 2600 rpm |

| Power take-off (PTO) power | 25.2 kW 33.9 hp |

| Steering hydraulics | 23.5 L/min 6.2 gpm |

| Implement hydraulics | 34.3 L/min 9.1 gpm |

| Hitch type | Category 1 |

| Lift capacity, 24-in. behind link arms | 995 kg 2194 lb |

| Standard transmission; forward/reverse | eHydro transmission |

| Cruise control | Standard |

| Approximate shipping weight (open-station; cab) | Open operator station (OOS): 1391 kg 3066 lb Cab: 1818 kg 4008 lb |

| Wheelbase | 1727 mm 68 in. |

Engine | |

| Family | |

| Manufacturer | Yanmar® |

| Engine model | 3TNV86CHT-MJTV |

| Engine power (gross) | SAE J1995 rated power: 33.3 kW 44.7 hp 45.3 PS at 2600 rpm |

| Power take-off (PTO) power | 25.2 kW 33.9 hp |

| Rated engine speed | 2600 rpm |

| Type | Diesel |

| Injection pump type | High pressure common rail direct injection |

| Aspiration | Turbocharged and intercooled |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | Three cylinders: 1.57 L 95.7 cu in. |

| Number of cylinders | Three |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 86 x 90 mm 3.4 x 3.54 in. |

| Compression ratio | 19.1:1 |

| Lubrication | Pressurized |

| Cooling system | Liquid |

| Air cleaner | Dual element |

| Engine torque at rated speed | 112.3 Nm 90 lb-ft |

| Fuel tank capacity | OOS: 37.4 L 10 U.S. gal. Cab only: 47.6 L 12.6 U.S. gal. |

Electrical | |

| Battery size | 500 CCA |

| Alternator (12-V) | 75 amp |

| Starter size | 1.4 kW 1.9 hp |

Fuel system | |

| Type | High pressure common rail direct injection |

| Fuel consumption | |

Transmission | |

| Standard transmission; forward/reverse | eHydro transmission |

| Optional transmission; forward/reverse | |

| Left-hand reverser | |

| Transmission gear ranges | Three-range, infinitely variable |

| Final drive | Spur gear |

| Brakes | Wet disk |

| Steering | Hydrostatic power steering |

| Clutch, wet/dry | |

| Clutch disk diameter wet clutch | |

| Axle capacity | Front 1450 kg 3197 lb Rear 1850 kg 4079 lb |

| Creeper | |

| Cruise control | Standard |

| Differential lock | |

| Drawbar maximum vertical load | |

Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 23.5 L/min 6.2 gpm Implement 34.3 L/min 9.1 gpm 57.8 L/min 15.3 gpm |

| Pump type | Single gear |

| Maximum operating pressure | 172 bar 2495 psi |

| Draft control sensing | Position control |

| Remote control valves available | Up to six rear remotes |

3-point hitch | |

| Type | Category 1 |

| Lift capacity, 24-in. behind link arms | 995 kg 2194 lb |

Power take-off (PTO) | |

| Standard | Independent rear: 540 rpm |

| Optional | Mid: 2100 rpm |

| Control | Lever and switch |

| Clutch | Wet disk |

| Brake (for mid and rear PTO) | Wet disk |

| Engagement method | |

Fluid capacities | |

| Crankcase with filter | 5.7 L 6 qt |

| Transmission and hydraulic system | 26.5 L 7 U.S. gal. |

Final drive | |

| Type | Spur gear |

| Differential lock | |

Operator station | |

| Rollover protective structure | Type Foldable |

| Platform - flat/straddle | One-piece semi flat |

| Gear shift location - console/floor | |

Cab | |

| Compliance | Complies with OSHA, SAE, and CSA standards for rollover protection |

| Visibility | 360 degree (angle) |

| Air conditioning, temperature differential | |

| Doors | Two |

| Noise rating | 80 dBA |

| Seat equipment | Scissor-link |

Dimensions | |

| Height | |

| Wheelbase | 1727 mm 68 in. |

| Front axle clearance | Minimum: 171 mm 6.7 in. Maximum: 299 mm 11.8 in. |

| Turning radius with brakes | 2.7 m 8.8 ft |

| Turning radius without brakes | 2.8 m 9.2 ft |

| Limited slip differential | |

| Approximate shipping weight (open-station; cab) | OOS: 1391 kg 3066 lb Cab: 1818 kg 4008 lb |

Tires | |

| Front | R1 Bar: 7-14 R3 Turf : 27x8.50-15 R3 Turf Special: 25/10.5LLx15 R4 Industrial: 25x8.5-14 or 27x8.5-15 |

| Rear | R1 Bar: 11.2-24 R3 Turf: 41x14-20 R3 Turf Special: 41x18LL-16.1 R4 Industrial: 15-19.5 or 43x16-20 |

| Front tread range | 1117 mm 44 in. |

| Rear tread spacing | 1031 mm 40.6 in. |

Miscellaneous | |

| Toolbox | |

| Tilt steering wheel | |

| 12-V Outlet | |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

LP25001 3pt hitch receiver hitch shown

LP25001 3pt hitch receiver hitch shown

Overview

Move trailers and other wheeled implements easily with the 3-point receiver hitch.

Benefits

- Easily move trailers and other wheeled implements

- Accepts standard 2-inch receivers ball mounts

- Compatible with CAT 1 IMatch Quick Hitch or and CAT 1 3pt tractor hitch

A horn provides audible alert to bystanders.

Allow 20 minutes to install.

Magnetic hitch pin

Magnetic hitch pin

Fits John Deere lawn and garden tow behind attachments.

- Strong magnetic grip

- Rust resistant

- Easy to install, secure fit

Ordering information

Customers, please contact your local John Deere dealer for availability and pricing information.

Magnetic hitch pin

Order number: LP63768

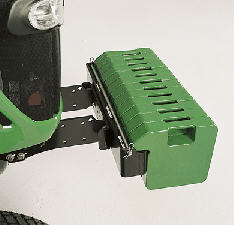

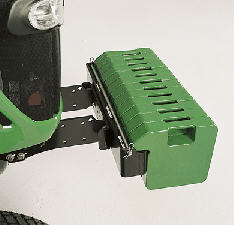

Toolbox kit for 3R Series Cab Tractors

Toolbox kit for 3R Series Cab Tractors

This toolbox is designed for installation only on 3R Series Cab Tractors.

This handy toolbox kit provides easy access and convenient storage for tools.

- Constructed of composite material that will not dent or rust

-

Dimensions:

-

Length: 330 mm (13 in.)

-

Width: 153 mm (6 in.)

-

Height: 141 mm (5.5 in.)

-

-

Can be easily removed, if desired

-

Installation time: 30 minutes

-

Kit includes toolbox and components required to install it on the outside of the tractor cab at the lower front corner of the cab

Toolbox installed outside of tractor cab

Toolbox installed outside of tractor cab

LP95637 Tractor cover shown

LP95637 Tractor cover shown

Overview

Provide all-weather protection to the tractor when not in use with a tractor cover.

Benefits

- Weather resistant material

- Protects against UV damage, rain, dirt, etc.

- Keeps the seat dry

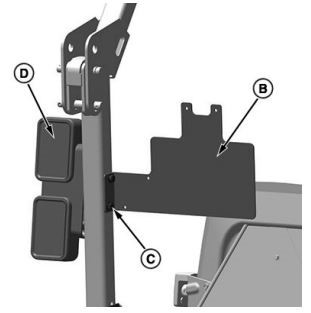

Cab Operator's Station

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

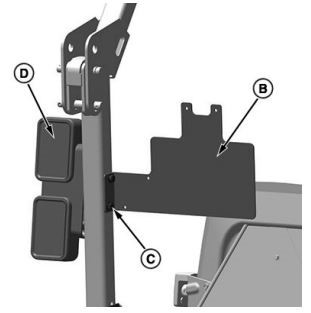

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

RAM is a trademark of National Products Inc.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

RAM is a trademark of National Products Inc.

External mirror kit

External mirror kit

Dual external mirrors provide a wide rear view of road or field and can be ordered for use on cab models. This kit contains one left-side and one right-side mirror with mounting hardware.

Rear wiper kit

Rear wiper kit

The rear wiper kit provides better rear visibility during inclement weather. It includes a wiper and a wiper nozzle that disperses fluid to clean the window.

BXX10277 License plate kit shown

BXX10277 License plate kit shown

Overview

License plate kits allow an operator to display a license plate on the tractor in order to meet local laws and regulations in which to drive on public roads.

LVB24856 Rear wiper kit shown

LVB24856 Rear wiper kit shown

Overview

The rear wiper kit provides better rear visibility during inclement weather. It includes a wiper and a wiper nozzle that disperses fluid to clean the window.

LVB24856 Rear wiper kit shown

LVB24856 Rear wiper kit shown

Overview

The rear wiper kit provides better rear visibility during inclement weather. It includes a wiper and a wiper nozzle that disperses fluid to clean the window.

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

- Self-leveling action reduces spills

- Durable design for rough environments

- Easy adjustable mounting for ideal placement

- Includes John Deere branded beverage insulator

- Compatible with most monitor brackets and all 10-mm threaded bosses

Front Weights

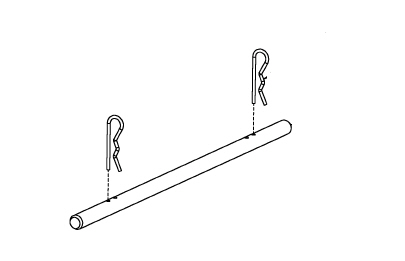

Weight kit

Weight kit

Rod and pins that allow weights to be bolted together to remain on tractor.

Weight bracket extension installed on a 3120

Weight bracket extension installed on a 3120

Can be attached to tractor to allow using up to 12 front weights. Extension kit includes extension bracket, hardware, rod, and pins.

Order weights separately.

Allow 30 minutes to install.

NOTE: Front weights and front hitch are not compatible on same tractor.

Weight bracket extension installed on a 3120

Weight bracket extension installed on a 3120

Can be attached to tractor to allow using up to 12 front weights. Extension kit includes extension bracket, hardware, rod, and pins.

Order weights separately.

Allow 30 minutes to install.

NOTE: Front weights and front hitch are not compatible on same tractor.

R51680 Front Quik-Tatch™ weights shown

R51680 Front Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

Overview

Weights can be installed on the front of a tractor when additional ballast is needed.

NOTE: The weight bracket and weights are not compatible when the loader is installed on the tractor. See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Benefits

- Increased ride comfort

- Increased stability

- Acts as a counterbalance to heavy attachments on the front or rear of the tractor.

R51680 Front Quik-Tatch™ weights shown

R51680 Front Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

Overview

Weights can be installed on the front of a tractor when additional ballast is needed.

NOTE: The weight bracket and weights are not compatible when the loader is installed on the tractor. See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Benefits

- Increased ride comfort

- Increased stability

- Acts as a counterbalance to heavy attachments on the front or rear of the tractor.

Front Wheels and Tires

Tire chains provide added traction in snowy and icy conditions.

Tire chains provide added traction in snowy and icy conditions.

Hydraulics

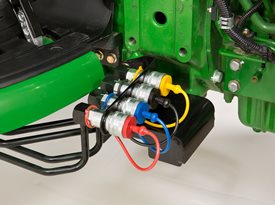

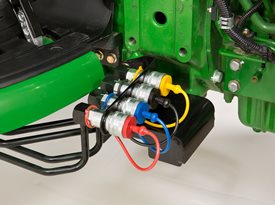

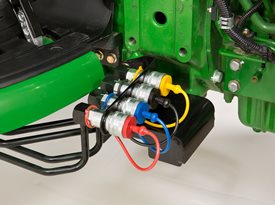

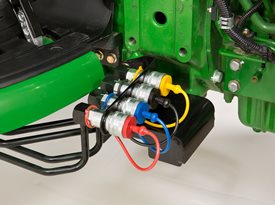

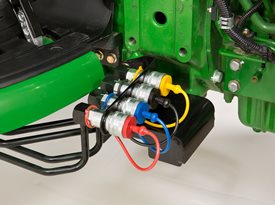

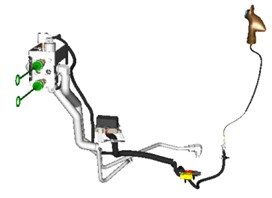

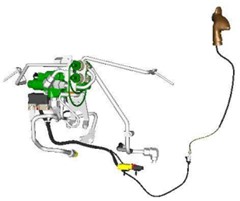

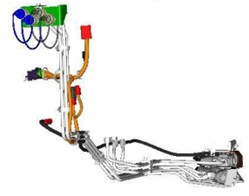

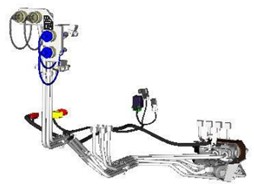

SCV

SCV

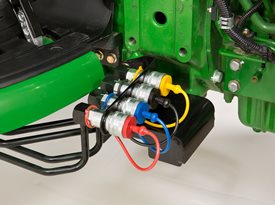

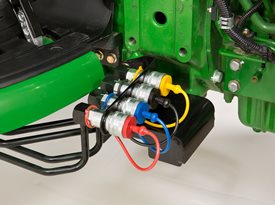

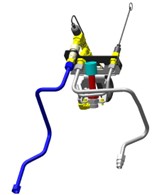

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

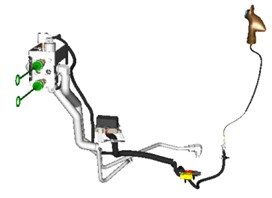

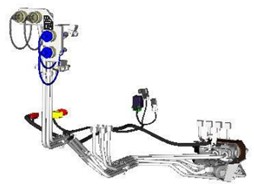

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

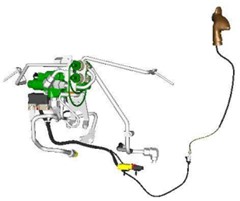

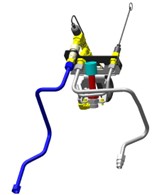

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

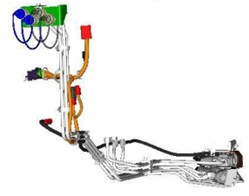

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

SCV

SCV

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

SCV

SCV

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

SCV

SCV

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

SCV

SCV

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

BLV10887 EH 3rd Rear SCV kit shown

BLV10887 EH 3rd Rear SCV kit shown

BLV10362 EH 3rd Rear SCV kit shown

BLV10362 EH 3rd Rear SCV kit shown

BLV10961 EH 3rd Rear SCV kit shown

BLV10961 EH 3rd Rear SCV kit shown

BLV10500 EH 3rd Rear SCV kit shown

BLV10500 EH 3rd Rear SCV kit shown

BLV10649 Electric Diverter Kit shown

BLV10649 Electric Diverter Kit shown

BLV10983 Electric Diverter Kit shown

BLV10983 Electric Diverter Kit shown

BLV10761 Dual Rear SCV Kit shown

BLV10761 Dual Rear SCV Kit shown

BLV10650 Top and Tilt Kit shown

BLV10650 Top and Tilt Kit shown

BLV10962 Power Beyond Kit shown

BLV10962 Power Beyond Kit shown

BLV10964 Power Beyond Kit shown

BLV10964 Power Beyond Kit shown

BLV11010 Power Beyond Kit shown

BLV11010 Power Beyond Kit shown

Overview

Unlock a tractors capability with hydraulic kits that allow you to add additional implements and attachments such as brooms, backhoes, grapples and rotary cutters.

SCV

SCV

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

SCV

SCV

The tractor is base equipped with a dual mid-selective control valve (SCV).

- Two sets of right-hand-side-mounted couplers allow raising/lowering boom and curling/dumping bucket

- Large, 0.9-cm (3/8-in.) diameter quick-couplers are used for maximum oil flow to implements

- Hydraulic valves have excellent featherability for smooth operation of equipment

- Couplers are color-coded for correct hookup

Optional rear hydraulic couplers - SCVs

Up to five additional SCVs can be added:

- Single rear electrohydraulic (EH) SCV (EH third SCV)

- Dual rear SCV (fourth and fifth SCV)*

- Electric diverter kit (includes two additional SCVs)

- Power beyond

*NOTE: Only available on 3R Open-Station Tractors.

Single rear EH third SCV

EH third SCV

EH third SCV

- Includes rear-mounted couplers, hydraulic lines, and SCV lever

Fourth and fifth rear SCV kit (dual rear SCV)

Fourth and fifth SCV controls

Fourth and fifth SCV controls

- Contains two rear–mounted couplers, hydraulic lines, and control levels (not compatible with 3R Cab Tractors)

Diverter valve kit

- Contains diverter valve, electric diverter switch, hydraulic lines, and two SCV couplers

- Allows the hydraulic oil to be diverted to either the front or rear couplers, as desired

Power beyond kit

- The power beyond kit contains rear-mounted couplers and hoses to access pressurized oil at the rear of the tractor; the kit is used for equipment such as a backhoe or log splitter

- Couplers are 1.3-cm (1/2-in.) diameter for maximum oil flow to implements

SCV controls

Single control lever/selective control lever

Single control lever/selective control lever

SCV safety lock lever

SCV safety lock lever

- Single control lever (A) makes operation of a loader or other implement fast and simple

- SCV safety lock lever (B) allows the operator to control the type of SCV lever movement needed for a particular operation or situation

- The SCV safety lock lever in the top position, indicated by the unlocked lock, allows operation of the SCV lever in all directions; operation of the SCV is totally unlocked

- The regeneration (REGEN) position on the bucket spool is available only with the SCV safety lock lever in the top position. As the lever is moved to the right (bucket dump) a slight bump can be felt mid-travel. Continued movement of lever past this bump activates REGEN position on spool.

- Loader operation may benefit from the use of the REGEN function. Regenerative hydraulics allow for faster bucket cycle times

- The REGEN function allows heavily loaded loader buckets to dump at a faster rate; however, lightly-loaded buckets do not benefit from this function and should be operated in the middle position

- Moving the SCV safety lock lever to the middle position prohibits the engagement of the REGEN function of the SCV; this position is recommended for all attachments except for the front loader with light loads

- Moving the SCV safety lock lever to the bottom position will prohibit SCV lever movement in all directions, thus totally locking operation of the SCV

BLV10887 EH 3rd Rear SCV kit shown

BLV10887 EH 3rd Rear SCV kit shown

BLV10362 EH 3rd Rear SCV kit shown

BLV10362 EH 3rd Rear SCV kit shown

BLV10961 EH 3rd Rear SCV kit shown

BLV10961 EH 3rd Rear SCV kit shown

BLV10500 EH 3rd Rear SCV kit shown

BLV10500 EH 3rd Rear SCV kit shown

BLV10649 Electric Diverter Kit shown

BLV10649 Electric Diverter Kit shown

BLV10983 Electric Diverter Kit shown

BLV10983 Electric Diverter Kit shown

BLV10761 Dual Rear SCV Kit shown

BLV10761 Dual Rear SCV Kit shown

BLV10650 Top and Tilt Kit shown

BLV10650 Top and Tilt Kit shown

BLV10962 Power Beyond Kit shown

BLV10962 Power Beyond Kit shown

BLV10964 Power Beyond Kit shown

BLV10964 Power Beyond Kit shown

BLV11010 Power Beyond Kit shown

BLV11010 Power Beyond Kit shown

Overview

Unlock a tractors capability with hydraulic kits that allow you to add additional implements and attachments such as brooms, backhoes, grapples and rotary cutters.

Lighting

The beacon light may be required for certain governmental or commercial applications. This kit consists of a rotating, high-intensity light that rests inside an amber-colored safety lens. A rocker switch controls its actuation. It can be located on the right-hand control panel for convenient access.

The top of the beacon light is 8 in. above the cab roof.

Allow 30 minutes for installation.

The forward-lighting kit provides extra visibility when working in dark conditions. Lights attach to the brush guards located on the rollover protective structure (ROPS). Each kit contains two lights.

NOTE: Requires BLV10400 warning light brush guard kit and LVB26026 light kit harness. Not compatible with LVB25547 rear work light kit (1023E).

NOTE: Requires BLV10400 warning light brush guard kit. Not compatible with LVB25547 rear work light kit (1025R, 2025R, 2032R, 2038R, 3025E, 3032E, 3038E, 4105, 4044M, 4052M, 4066M).

NOTE: Requires BLV10620 premium warning light brush guard kit. Not compatible with LVB25547 rear work light kit (3033R, 3039R, 3046R, 4044R, 4052R, 4066R).

Rollover protective structure (ROPS) mounted LED work lights

An optional LED work light kit is available for all open-station compact utility tractors. These lights provide extra visibility when working in dark conditions and have 180-degree rotation to face forward or backward. The kit contains two lights and the mounting hardware required for installation.

This lighting kit is mounted to the warning light brush guard kit, which is mounted to the ROPS and requires attachment BLV10400 for installation.

The halogen work light kit attachment is still available (LVB25546).

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series Tractor

ROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series Tractor

ROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

Rear work light kit

Rear work light kit

-

Provides light to rear of tractor for evening work

-

For cab, kit contains two lights

Allow 30 minutes to install.

Rear work light

Rear work light

This kit provides light to the rear of the tractor for evening work.

For open-station tractors only, this kit contains individual light.

Allow 30 minutes to install.

NOTE: Kit includes one rear light.

NOTE: Both the rear- and forward-work lights are compatible together and with the light-brush guard kits. The light kit contains a two-to-four pigtail that plugs into the main harness, as if only plugging one set of lights, providing two sets of plugs to use for forward and rear-work lights. The forward light is installed on top of the brush guard, and the rear light is installed inside the ROPS using the bolt holding the light and brush guard on.

NOTE: For 102E3 and 1026R Tractors – kit interference during backhoe operations (mounted inside ROPS) – use LVB25546 forward-light kit as an alternative.

Open Operator's Station

The air-ride seat suspension provides vertical and horizontal seat suspension for maximum operator comfort in any terrain. Key benefits include:

- Maximum ride comfort and quality, thus minimizing operator fatigue

- Exclusive fore/aft isolation provides lateral suspension to dampen out backward/forward movement

- Dampens lower frequency vibration better than mechanical suspensions

- Operator weight capacity is increased to 330 lb

- Close-out boot provides enhanced appearance

This kit includes air-ride seat suspension, adapter plate, close-out boot and push pins, and wiring harness. The kit does not include an actual seat, but rather the suspension kit replaces the mechanical standard suspension on the existing seat.

For open-station tractors only.

Canopy

Canopy

The canopy attaches to the rollover protective structure (ROPS) to protect the operator from inclement weather.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

Canopy mounting kit

Canopy mounting kit

The canopy attaches to the rollover protective structure (ROPS) to protect the operator from inclement weather.

For open-station tractors only.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

LP95233 large seat cover shown

LP95233 large seat cover shown

LP68694 small seat cover shown

LP68694 small seat cover shown

- Cushioned seat for extra comfort

- Fabric coated for maximum water resistance and repellency

- Elastic cord locks around safety sign on seat back

- Elastic cord in bottom hem for a custom fit

- Handy zippered storage case

BXX10277 License plate kit shown

BXX10277 License plate kit shown

Overview

License plate kits allow an operator to display a license plate on the tractor in order to meet local laws and regulations in which to drive on public roads.

Umbrella

Umbrella

Provides the operator the necessary shade and protection from the elements.

-

Attaches to the tractor's rollover protective structure (ROPS)

-

For open-station tractors only

Rear Wheel Weights

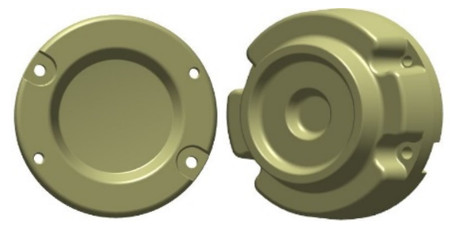

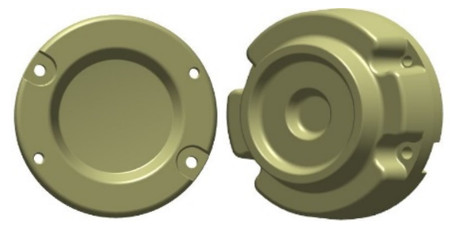

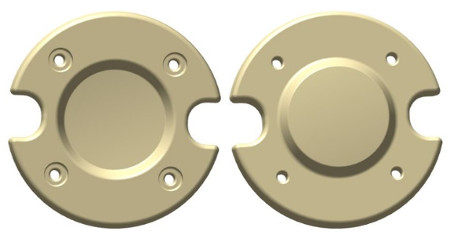

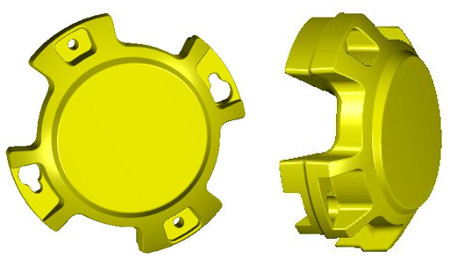

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

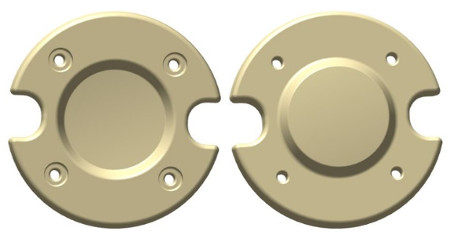

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

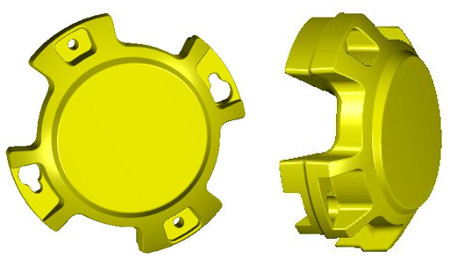

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

Rear Wheels and Tires

Tire chains provide added traction in snowy and icy conditions.

Tire chains provide added traction in snowy and icy conditions.

Three-Point Hitch

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch:

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

One of the greatest customer concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: In the picture above, you see the bushing set. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 0.76-0.77 in.

- Outside diameter: 1.24-1.25 in.

- Lower bushings

- Inside diameter: 0.88 to 0.89 in.

- Outside diameter: 1.43 to 1.44 in.

Reviews

Location: central ky

Length of Ownership: 1yearOrLonger

Usage: Daily