2032R

Compact Tractor

- Standard LED headlights and fender lights

- Comfortable, marine-grade seat stays in top condition

- Larger, heavier frame for added stability

- Up to 72" AutoConnect™ mid-mower deck can be installed or removed in under 5 minutes

Starting At:

$28,300.00

View Product Brochure

Features

Yanmar 3-cylinder, TNV series diesel engine

Yanmar 3-cylinder, TNV series diesel engine

2032R

The 1.642-L (100.2-cu in.) displacement, liquid-cooled 3TNV88C-NJT Yanmar® diesel engine provides 22.9 kW ( 30.7 hp) to the 2032R.

Model |

Number of cylinders |

Engine displacement |

Aspiration |

Gross engine power* |

Gross engine PS* |

Power take-off (PTO) power* |

2032R |

3 |

1.642 L (110.2 cu in.) |

Natural |

22.9 kW (30.7 hp) |

31.2 PS |

18 kW (24.2 hp) |

*Engine kW (hp), gross SAE J1995: 22.9 (30.7) at 2500 rpm, PS

Displacement, L (cu in).: 1.642 (100.2)

2038R

The 1.568-L (95.8-cu in.) displacement, turbocharged liquid-cooled 3TNV86T-NJT Yanmar diesel engine provides 27.4 kW ( 36.7 hp) to the 2038R.

Model |

Number of cylinders |

Engine displacement |

Aspiration |

Gross engine power* |

Gross engine PS* |

PTO power* |

2038R |

3 |

1.568 L (95.8 cu in.) |

Turbocharged |

27.4 kW (36.7 hp) |

37.2 PS |

22.7 kW (30.4 hp) |

*Engine kW (hp), gross SAE J1995: 27.4 (36.7) at 2500 rpm, PS

Displacement, L (cu in.): 1.568 (95.8)

The engine uses the latest technologies to optimize fuel economy, improve control and accuracy, and reduce environmental impact.

The common rail system (CRS) optimizes fuel economy and reduces operating costs. High-pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and a lower cost of operation.

The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions.

The engine comes with an aftertreatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC).

After many hours of use, the exhaust filter may require an ash removal service.

Parked filter cleaning

In some instances where passive and active filter cleaning have not fully cleaned the particulate matter from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process.

The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details.

The emissions system on this engine constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

For more information regarding Environmental Protection Agency (EPA) regulations and the technology behind John Deere Integrated Emissions Control systems, click here.

Yanmar TNV Series engine offers these features:

- Economical cast-in-block cylinder design for good cooling and long life

- Direct fuel injection

- Improves starting

- Injects fuel directly on top of pistons for more efficient combustion

- Develops more horsepower per gallon of fuel than indirect injection engines

- Aluminum alloy pistons are lightweight to reduce connecting rod bearing loads and provide good heat transfer characteristics

- Design permits tighter tolerances and neutralizes expansion of the piston, which reduces blow-by and noise from piston slap

- Top rings are higher on the piston and a thinner head gasket is used to greatly reduce the volume of unburned waste gases and increase combustion efficiency

- Timing gears and injector drive gears have a helical profile to reduce engine noise

- Auto-bleed fuel system

- There is no need to prime the system if the tractor runs out of fuel

- The system self-primes the injection pump, lines and injectors, providing fast fuel recovery for easier starting

- High-capacity lubrication system provides filtered oil, under pressure, to all engine bearings for long life

- Fuel filter with replaceable element

- Water separator with additional replaceable filter element

- See-through coolant recovery tank permits operator to check coolant level without removing radiator cap

- Dry-type air cleaner with safety element

- Dual element design for added engine protection

- Air cleaner service indicator is standard equipment on all models and alerts the operator on the instrument panels

- Easy access to engine check and fill points on the right-hand side of the tractor by removing the side panels

Yanmar is a trademark of Yanmar Co., Ltd.

DOC/DPF

Depending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

- A prescribed time-based estimation of needed filter cleaning

- DOC/DPF pressure sensors

- A particulate matter buildup estimation based on load conditions

Once one of the three conditions have been met, filter cleaning will occur. There are three different types of filter cleaning processes:

- Passive filter cleaning

- Active filter cleaning

- Parked filter cleaning

Passive filter cleaning

Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

Active filter cleaning

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then particulate matter is removed using active filter cleaner.

To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize particulate matter.

It is important to note that at no time is fuel in the DOC/DPF ignited, and there is no interruption to tractor operation.

Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

The 2032R and 2038R Tractors are equipped with a two-range hydrostatic transmission (HST) incorporated in a die-cast aluminum transmission case. Fluid under pressure transmits engine power to the drive wheels via a closed-loop pump and motor arrangement. Infinite ground speeds allow the operator to match the speed of the tractor to the job.

- No clutching for fast and easy direction changes

- Twin Touch™ foot pedals for quick and easy forward/reverse operation

- Transmission oil cooler cools transmission oil for longer transmission life

Safety features of the HST transmission include:

- The tractor will only start with the range lever in neutral

- If the range lever is in gear when the key is turned to the start position, the instrument panel instructs the operator to shift to neutral

- The engine will shut off if the operator leaves the seat and the power take-off (PTO) is engaged

Twin Touch foot controls

Twin Touch foot controls

Twin Touch foot controls

Key John Deere advantages – John Deere’s Twin Touch foot controls offer several key advantages over competitive HST models tractors.

- Some competitive hydrostatic tractors use a treadle pedal (toe-heel) design foot control for operation of the HST

- Requires the operator to use both toe and heel to change direction, resulting in increased operator fatigue

- The Twin Touch configuration also makes it easier to inch the tractor forward or rearward (i.e., when attaching to implements)

Integrated hydrostatic pump and motor

- Sauer-Danfoss® manufacturer provides the integrated pump and motor; this assures that the components are matched to each other, providing maximum efficiency

- Provides strength and durability needed for operating such attachments as loaders and backhoes

- One reservoir (with one check-point and fill point) for the transmission, differential, and hydraulic system speeds up daily maintenance

- Mechanically actuated by Twin Touch foot pedals allow the operator to select both directions of travel and speed with the touch of a toe

Cruise control

An electronic cruise control is standard equipment on the 2032R and 2038R Tractors. Cruise control is electronically engaged and disengaged using a toggle switch located on the right-hand console.

- Maintains desired forward speed without having to touch the forward pedal

- To disengage the cruise control, either apply pressure to the brake pedal or disengage the cruise control switch

Sauer-Danfoss is a trademark of Sauer-Danfoss Incorporated.

Operator Station

Operator Station

The operator station has been designed to allow for greater operator comfort and increased visibility. The ergonomic layout and convenient color coded controls allow for easy identification and operation. The design of the operator station allows operators to sit “in” as opposed to “on” which provides comfort and increased stability.

Below are other key features of the 2032R and 2038R Tractor operator’s station:

- Sloping hood design provides improved visibility

- Plenty of room for comfortable operation

- Cup holder, multiple storage compartments and a 12V outlet ensures an organized operator station

- Rubberized floor mat design to reduce vibration and noise

- Step-through operator platform makes getting on and off the tractor easy

- Fender-mounted handrails, large and easy to grab, assist the operator when getting on and off the tractor

- Controls have been raised and integrated into the fender for operator comfort and ease of use

- Large, easy to read decals provide clear instructions for experienced and even non experienced operators

- Front horizontal exhaust for increased operator visibility

- If the operator leaves the tractor seat when the transmission, mid PTO, or rear PTO is engaged, the engine will shut down

- For applications where out-of-seat PTO operation is required, the following criteria must be met: transmission in neutral, park brake engaged, and PTO selector set to rear only. See operator's manual for specific instructions.

- Specially designed panels route hot air flow from the engine compartment under the tractor instead of directly onto the operator

Left-side step

Left-side entrance step

Left-side entrance step

- The left-side step allows for easy access on and off the tractor

- Foot platform has a non-skid surface

Premium seat

Premium high-back seat

Premium high-back seat

The thick, soft padding on this seat provides a smooth and comfortable ride with added weather resistance from marine grade vinyl that is easy to clean. A high, scalloped back makes it easier for the operator to turn to view rear implements.

- Seat adjusts fore/aft for operator convenience

- Seat flips forward for protection from the elements

- High seat back and armrests are in base equipment and allow for a more comfortable operation

- Retractable seat belt feature prevents the seat belt from becoming tangled in the seat suspension and controls

Key features of the operator’s station include:

- Tilt steering wheel design in base equipment on the 2032R and 2038R Tractors

- Allows the operator to adjust the steering wheel to the most comfortable position

- Provides additional clearance for the operator to enter and exit the tractor

- Provides easy return to the fully raised position

- Provides plenty of room for comfortable operation

Tilt steering lever

Tilt steering lever

- Easy-fold ROPS allows tractor to be used or stored in low clearance environments

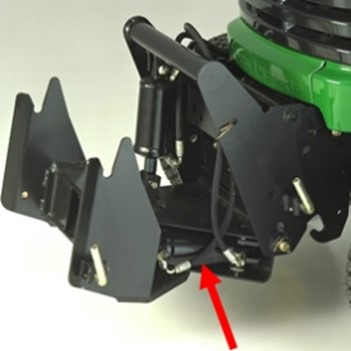

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

One of the greatest operator concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the American Society of Agricultural and Biological Engineers (ASABE) Category 1 Standard S278.6 for quick-attach hitches.

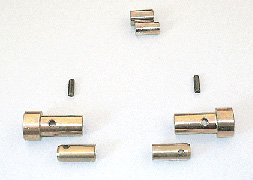

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: The bushing set can be seen in the picture above. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 1.93-1.95 cm (0.76-0.77 in.)

- Outside diameter: 3.15-3.18 cm (1.24-1.25 in.)

- Lower bushings

- Inside diameter: 2.24-2.26 cm (0.88 to 0.89 in.)

- Outside diameter: 3.63-3.66 cm (1.43 to 1.44 in.)

Instrument panel

Instrument panel

CommandCut™ controls

CommandCut™ controls

The 2032R and 2038R tractors features the CommandCut™ mower deck lift system, which allows quick and accurate adjustments of the mower deck with the turn of a dial and the bump of a lever. Control callouts make operation simple and repeatable. The height of cut setting dial and raise/lower lever are conveniently located on the right-hand console and easily accessible by the operator. Some of the key benefits of this system are:

- Installing CommandCut™ only requires a simple calibration after installation. It is a true “plug-and-play” system as no controller programming is required.

- Inhibits PTO operation when mower deck is in the install position to prevent PTO driveling and mower deck blade damage

- Eliminates the need for hydraulic power and components, thus dedicating all hydraulic capacity to other implements or tract functions

- Fewer hydraulic components means fewer hydraulic leaks, especially when working on sensitive turf

- Precise height of cut with no drift or leakdown

- System can be calibrated to different tire sizes to maintain precision

- Minimum effort required to set height of cut and to raise/lower the mower deck which reduces operator fatigue

- Easy to read graphical interface on the instrument panel allows operator to glance at the desired height of cut while staying focused on mowing

- Built in transport lock can be activated from the seat by turning the height of cut dial to position 6 and raising the deck to the highest position

Regular service and maintenance are essential to the performance, productivity, and longevity of the tractor.

- Tractors are equipped with extensive onboard self-diagnostic capabilities and are fully compatible with the John Deere-exclusive ServiceADVISOR™ system.

- Four quarter turn fasteners allow operators to easily remove the engine side panels without tools to access to the engine compartment.

Quarter turn fasteners

Quarter turn fasteners

Right tractor side panel removed

Right tractor side panel removed

- Easy access to regular service points minimizes service time

- Daily service checks, such as checking the engine oil or water separator, can be done without opening the hood or removing the tractor side panels

- Tractors are equipped with an electronic air filter restriction indicator that alerts the operator when the air filter needs to be cleaned or changed

Air filter restriction sensor

Air filter restriction sensor

- Daily service requirements are minimal and simple to accomplish. Most service interval requirements can be performed with a basic understanding of procedures and common tools.

- All external engine, fuel and transmission filters are easily accessible

- Increased service intervals lessen overall cost of ownership

- Hydraulic oil service interval increased to 1200 hours when using Hy-Gard™ products

- Hydraulic oil filter will need to be changed every 400 hours

- Fuel tank is located on the rear of the tractor to allow for easy access when fueling

Fuel Tank

Fuel Tank

- Gas-lift hood support eliminates the need for a mechanical prop rod

Gas-lift hood shocks

Gas-lift hood shocks

All items in the daily service schedule can be performed without the use of tools:

- Engine oil, hydraulic oil, coolant level, and the water separator can be conveniently accessed

- The engine can be easily accessed by simply raising the hood for more periodic maintenance checks

NOTE: Always refer to the operator’s manual for complete maintenance and service recommendations.

Specs & Compare

Key Specs | 2032R Current Model |

| Engine power (gross) | SAE J1995 rated power: 22.9 kW 30.7 hp 31.2 PS at 2500 rpm |

| Power take-off (PTO) power | 18 kW 24.2 hp |

| Steering hydraulics | 15 L/min 4 gpm |

| Implement hydraulics | 20.2 L/min 5.3 gpm |

| Hitch type | Category 1 |

| Lift capacity, 24-in. behind link arms | 615 kg 1356 lb |

| Standard transmission; forward/reverse | Hydrostatic transmission (HST) |

| Cruise control | Standard |

| Approximate shipping weight (open-station; cab) | Open station: 1306 kg 2879 lb Cab: Not applicable |

| Wheelbase | 1723 mm 67.8 in. |

Engine | |

| Family | |

| Manufacturer | Yanmar® |

| Engine model | 3TNV88C-NJT2 |

| Engine power (gross) | SAE J1995 rated power: 22.9 kW 30.7 hp 31.2 PS at 2500 rpm |

| Power take-off (PTO) power | 18 kW 24.2 hp |

| Rated engine speed | 2500 rpm |

| Type | Direct Injection |

| Injection pump type | Direct Injection |

| Aspiration | Natural |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | Three cylinders: 1.642 L 100.2 cu in. |

| Number of cylinders | Three |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 88x90 mm 3.46x3.54 in. |

| Compression ratio | 19.1:1 |

| Lubrication | Pressurized |

| Cooling system | Water pump |

| Air cleaner | Dual element |

| Engine torque at rated speed | 87.5 Nm 64.5 lb-ft |

| Fuel tank capacity | 32 L 8.5 U.S. gal. |

Electrical | |

| Battery size | 500 CCA |

| Alternator (12-V) | 85 amp |

| Starter size | 1.4 kW 1.9 hp |

Fuel system | |

| Type | Direct Injection |

| Fuel consumption | |

Transmission | |

| Standard transmission; forward/reverse | Hydrostatic transmission (HST) |

| Optional transmission; forward/reverse | |

| Left-hand reverser | |

| Transmission gear ranges | |

| Final drive | Spur gear |

| Brakes | Wet disc |

| Steering | Power steering |

| Clutch, wet/dry | |

| Clutch disk diameter wet clutch | |

| Axle capacity | Front 880 kg 1940 lb Rear 1800 kg 3968 lb |

| Creeper | No |

| Cruise control | Standard |

| Differential lock | Yes |

| Drawbar maximum vertical load | |

Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 15 L/min 4 gpm Implement 20.2 L/min 5.3 gpm 35.2 L/min 9.3 gpm |

| Pump type | Dual gear |

| Maximum operating pressure | 172 bar 2495 psi |

| Draft control sensing | Position control |

| Remote control valves available | Up to three |

3-point hitch | |

| Type | Category 1 |

| Lift capacity, 24-in. behind link arms | 615 kg 1356 lb |

Power take-off (PTO) | |

| Standard | Rear: 543 rpm Mid: 1998 rpm |

| Optional | |

| Control | Independent |

| Clutch | Wet disc |

| Brake (for mid and rear PTO) | Wet disc |

| Engagement method | |

Fluid capacities | |

| Crankcase with filter | 4.5 L 4.8 qt |

| Transmission and hydraulic system | |

Final drive | |

| Type | Spur Gear |

| Differential lock | Yes |

Operator station | |

| Rollover protective structure | Type Foldable ASABE S478 |

| Platform - flat/straddle | Semi-flat |

| Gear shift location - console/floor | |

Cab | |

| Compliance | |

| Visibility | |

| Air conditioning, temperature differential | |

| Doors | |

| Noise rating | |

| Seat equipment | |

Dimensions | |

| Height | |

| Wheelbase | 1723 mm 67.8 in. |

| Front axle clearance | |

| Turning radius with brakes | 2.46 m 8.07 ft |

| Turning radius without brakes | |

| Limited slip differential | |

| Approximate shipping weight (open-station; cab) | Open station: 1306 kg 2879 lb Cab: Not applicable |

Tires | |

| Front | R1 Ag 7.00-12 R3 Turf 23x8.50-14 R4 Industrial 23x8.50-14 R3 Turf Radial 200/60 R15 |

| Rear | R1 Ag 12.4-16 R3 Turf 14-17.5 R4 Industrial 14-17.5 R3 Turf Radial 300/70 R20 |

| Front tread range | |

| Rear tread spacing | |

Miscellaneous | |

| Toolbox | Yes |

| Tilt steering wheel | Yes |

| 12-V Outlet | Yes |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

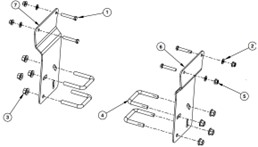

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Backhoes

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

Mechanical thumb shown on 485 backhoe

Mechanical thumb shown on 485 backhoe

Thumb schematic shown

Thumb schematic shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10891 Hydraulic Thumb Kit shown

BXX10891 Hydraulic Thumb Kit shown

Overview

Backhoe thumb kits add increased functionality of the backhoe by allowing an operator to easily grab items such as logs and debris. Thumb kits come in both mechanical and hydraulic versions with fixed or on the fly position adjustments.

Mechanical thumb shown on 485 backhoe

Mechanical thumb shown on 485 backhoe

Thumb schematic shown

Thumb schematic shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10891 Hydraulic Thumb Kit shown

BXX10891 Hydraulic Thumb Kit shown

Overview

Backhoe thumb kits add increased functionality of the backhoe by allowing an operator to easily grab items such as logs and debris. Thumb kits come in both mechanical and hydraulic versions with fixed or on the fly position adjustments.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

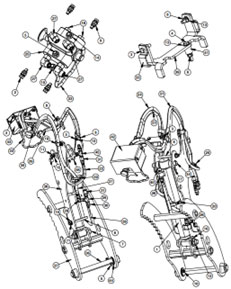

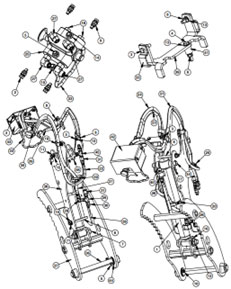

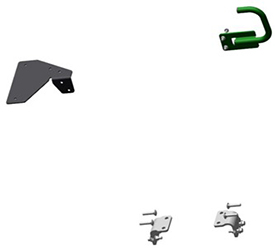

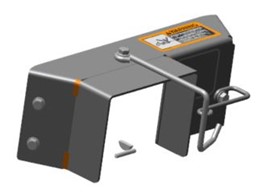

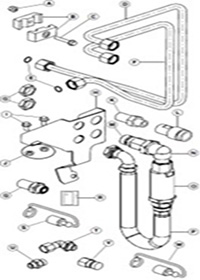

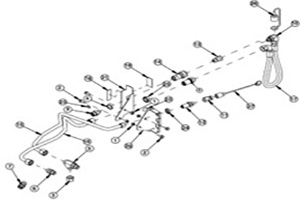

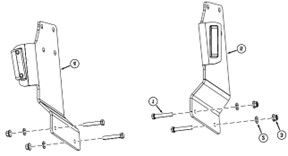

BXX10279 Subframe mounting kit shown

BXX10279 Subframe mounting kit shown

BLV10594 Subframe mounting kit shown

BLV10594 Subframe mounting kit shown

BXX10278 Grab Handle and mounting parts shown

BXX10278 Grab Handle and mounting parts shown

Overview

Backhoe mounting kits are required to add a backhoe to a compact utility tractor.

NOTE: Power beyond kit is required on all tractors for proper backhoe installation and functionality

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

Front Hitch

Front 3-point hitch with A-frame adapter (3020 Series Tractor shown)

Front 3-point hitch with A-frame adapter (3020 Series Tractor shown)

This hitch can be ordered as an option code within the given implements with which it is compatible (59 Snow Blower, 366 Front Blade, or 60 Front Broom), or it can be ordered as an attachment for field conversion. If the operator already has the hitch, the other implements will need to be ordered with the less hitch code so a second hitch is not ordered.

Front 3-point hitch with A-frame adapter (3020 Series Tractor shown)

Front 3-point hitch with A-frame adapter (3020 Series Tractor shown)

This hitch can be ordered as an option code within the given implements with which it is compatible (59 Snow Blower, 366 Front Blade, or 60 Front Broom), or it can be ordered as an attachment for field conversion. If the operator already has the hitch, the other implements will need to be ordered with the less hitch code so a second hitch is not ordered.

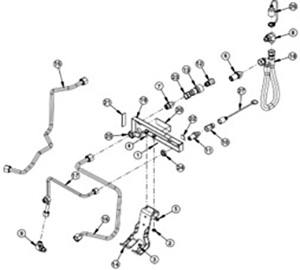

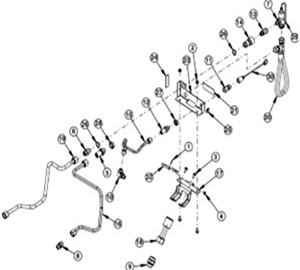

BLV10708 Quick Hitch shown

BLV10708 Quick Hitch shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10796 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10680 Front Quick Hitch to Tractor Interface Kit shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10786 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10681 Front PTO 2000 RPM CCW Mid Drive shown

BLV10793 Snow Blower Mounting Kit shown

BLV10793 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BXX10906 Snow Blower Mounting Kit shown

BLV10899 Snow Blower Drive Shaft shown

BLV10899 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BXX10678 Snow Blower Drive Shaft shown

BLV10794 52” Broom Attaching Kit shown

BLV10794 52” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10795 60” Broom Attaching Kit shown

BLV10900 Broom Drive Shaft shown

BLV10900 Broom Drive Shaft shown

Front Quick Hydraulic Angling Kit example shown

Front Quick Hydraulic Angling Kit example shown

Overview

Front quick hitch kits allow an operator to quickly install snow blowers, brooms and blades to the front of the tractor.

NOTE: Depending on the tractor and implement type, additional kits may be required to complete the install

Benefits

- Quick installation of implements

- Increased productivity

- Adaptable for various front mounted implements

Front Weights

R51680 Front Quik-Tatch™ weights shown

R51680 Front Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

Overview

Weights can be installed on the front of a tractor when additional ballast is needed.

NOTE: The weight bracket and weights are not compatible when the loader is installed on the tractor. See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Benefits

- Increased ride comfort

- Increased stability

- Acts as a counterbalance to heavy attachments on the front or rear of the tractor.

R51680 Front Quik-Tatch™ weights shown

R51680 Front Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

UC13263 Quik-Tatch™ weights shown

Overview

Weights can be installed on the front of a tractor when additional ballast is needed.

NOTE: The weight bracket and weights are not compatible when the loader is installed on the tractor. See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Benefits

- Increased ride comfort

- Increased stability

- Acts as a counterbalance to heavy attachments on the front or rear of the tractor.

Front Wheels and Tires

Hydraulics

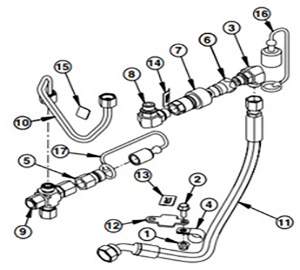

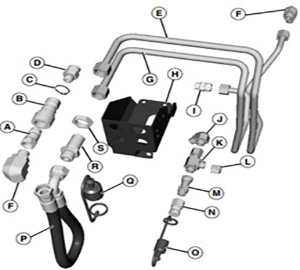

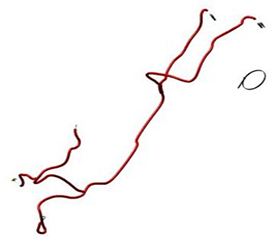

Power beyond kit example shown

Power beyond kit example shown

BLV11238 Power beyond kit shown

BLV11238 Power beyond kit shown

BLV10881 Power Beyond Kit shown

BLV10881 Power Beyond Kit shown

BLV11010 Power Beyond Kit shown

BLV11010 Power Beyond Kit shown

LVB25221 Power Beyond Kit shown

LVB25221 Power Beyond Kit shown

LVB25505 Power Beyond Kit shown

LVB25505 Power Beyond Kit shown

LVB26069 Power Beyond Kit shown

LVB26069 Power Beyond Kit shown

LVB25781 Power Beyond Kit shown

LVB25781 Power Beyond Kit shown

BLV10962 Power Beyond Kit shown

BLV10962 Power Beyond Kit shown

BLV10964 Power Beyond Kit shown

BLV10964 Power Beyond Kit shown

LVB25085 Power Beyond Kit shown

LVB25085 Power Beyond Kit shown

LVB25780 Power Beyond Kit shown

LVB25780 Power Beyond Kit shown

LVB26071 Power Beyond Kit shown

LVB26071 Power Beyond Kit shown

LVB25512 Power Beyond Kit shown

LVB25512 Power Beyond Kit shown

LVB26066 Power Beyond Kit shown

LVB26066 Power Beyond Kit shown

LVB25220 Power Beyond Kit shown

LVB25220 Power Beyond Kit shown

BLV11068 Power Beyond Kit shown

BLV11068 Power Beyond Kit shown

BLV10969 Power Beyond Kit shown

BLV10969 Power Beyond Kit shown

Overview

Power beyond kits provide access of pressurized hydraulic oil at the rear of the tractor for operating attachments equipped with an open center control valve, such as a backhoe and log splitter when continuous hydraulic flow is required.

NOTE: When nothing is hooked up to the power beyond, it is critical the loop is closed to ensure proper hydraulic flow.

NOTE: Power beyond kits are not included in the backhoe frame attachments and must be ordered separately.

NOTE: See the serial number break table for reference to the start of model year 2011 Power Beyond serial_number_breaks_cuts

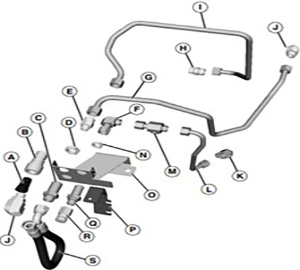

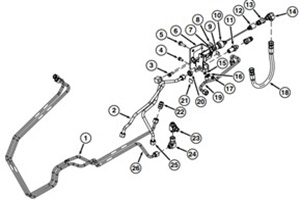

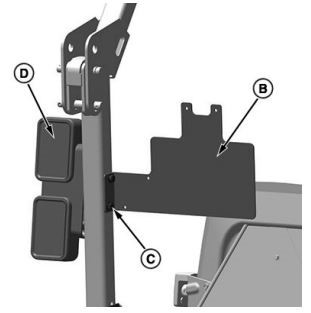

220R Loader with single point hydraulic connector shown

120R Loader with BXX10283 single point hydraulic connector shown

Overview

Available on 120R and 220R loaders, the hydraulic single-point connector saves the operator time and effort during the loader removal and installation process. This feature allows effortless connection or removal of boom and bucket hydraulic connection lines within seconds.

This single-point hydraulic coupler attachment supports two hydraulic circuits used to operate the loader boom and bucket.

The single point system contains two main sections: tractor and loader halves. The tractor half that remains on the tractor is securely mounted, utilizing a bracket that is held in the same place as the loader mounting frame. The loader half is flexible and when disconnected, remains with the loader (parked).

220R Loader with single point hydraulic connector shown

120R Loader with BXX10283 single point hydraulic connector shown

Overview

Available on 120R and 220R loaders, the hydraulic single-point connector saves the operator time and effort during the loader removal and installation process. This feature allows effortless connection or removal of boom and bucket hydraulic connection lines within seconds.

This single-point hydraulic coupler attachment supports two hydraulic circuits used to operate the loader boom and bucket.

The single point system contains two main sections: tractor and loader halves. The tractor half that remains on the tractor is securely mounted, utilizing a bracket that is held in the same place as the loader mounting frame. The loader half is flexible and when disconnected, remains with the loader (parked).

Lighting

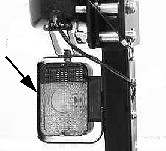

The forward-lighting kit provides extra visibility when working in dark conditions. Lights attach to the brush guards located on the rollover protective structure (ROPS). Each kit contains two lights.

NOTE: Requires BLV10400 warning light brush guard kit and LVB26026 light kit harness. Not compatible with LVB25547 rear work light kit (1023E).

NOTE: Requires BLV10400 warning light brush guard kit. Not compatible with LVB25547 rear work light kit (1025R, 2025R, 2032R, 2038R, 3025E, 3032E, 3038E, 4105, 4044M, 4052M, 4066M).

NOTE: Requires BLV10620 premium warning light brush guard kit. Not compatible with LVB25547 rear work light kit (3033R, 3039R, 3046R, 4044R, 4052R, 4066R).

Rollover protective structure (ROPS) mounted LED work lights

An optional LED work light kit is available for all open-station compact utility tractors. These lights provide extra visibility when working in dark conditions and have 180-degree rotation to face forward or backward. The kit contains two lights and the mounting hardware required for installation.

This lighting kit is mounted to the warning light brush guard kit, which is mounted to the ROPS and requires attachment BLV10400 for installation.

The halogen work light kit attachment is still available (LVB25546).

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series Tractor

ROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

ROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

Two guards are included in each kit and are for open-operator station (OOS) tractors only.

Rear work light

Rear work light

This kit provides light to the rear of the tractor for evening work.

For open-station tractors only, this kit contains individual light.

Allow 30 minutes to install.

NOTE: Kit includes one rear light.

NOTE: Both the rear- and forward-work lights are compatible together and with the light-brush guard kits. The light kit contains a two-to-four pigtail that plugs into the main harness, as if only plugging one set of lights, providing two sets of plugs to use for forward and rear-work lights. The forward light is installed on top of the brush guard, and the rear light is installed inside the ROPS using the bolt holding the light and brush guard on.

NOTE: For 102E3 and 1026R Tractors – kit interference during backhoe operations (mounted inside ROPS) – use LVB25546 forward-light kit as an alternative.

Open Operator's Station

LVB25334 Canopy Kit shown

LVB25334 Canopy Kit shown

LVB25332 Canopy Mounting Kit shown

LVB25332 Canopy Mounting Kit shown

BSJ10363 Canopy Mounting Kit shown

BSJ10363 Canopy Mounting Kit shown

BSJ10341 Canopy Mounting Kit shown

BSJ10341 Canopy Mounting Kit shown

Overview

The canopy attaches to the tractor’s rollover protective structure (ROPS) to protect operators from the sun and inclement weather.

BRE10349 canopy bracket kit parts

BRE10349 canopy bracket kit parts

Canopy system mounted on 6120E

Canopy system mounted on 6120E

The canopy bracket kits provide mounting solutions for the popular LVB25334 ABS canopy, allowing it to fit the rollover protective structure (ROPS) of the 2 Series through 6 Series as well as older open operator station 7 Series Tractors. The bracket system provides up to 15 degrees of total travel allowing the canopy to be adjusted horizontal to the ground, or pitched forward or backward to meet the specific needs of the operator. Adjustment of the pitch angle requires loosening of six nuts while mounted to the ROPS. The angle is then adjusted by holding the canopy at the desired pitch and tightening the nuts again.

Both of these kits include mounting brackets for the right-hand and left-hand side, all hardware, and installation instructions. The canopy itself (LVB25334) must be ordered additionally.

BXX10277 License plate kit shown

BXX10277 License plate kit shown

Overview

License plate kits allow an operator to display a license plate on the tractor in order to meet local laws and regulations in which to drive on public roads.

LP95637 Tractor cover shown

LP95637 Tractor cover shown

Overview

Provide all-weather protection to the tractor when not in use with a tractor cover.

Benefits

- Weather resistant material

- Protects against UV damage, rain, dirt, etc.

- Keeps the seat dry

Umbrella

Umbrella

Provides the operator the necessary shade and protection from the elements.

-

Attaches to the tractor's rollover protective structure (ROPS)

-

For open-station tractors only

Operator's Station

Rear Power Take-Off (PTO)

Rear Wheel Weights

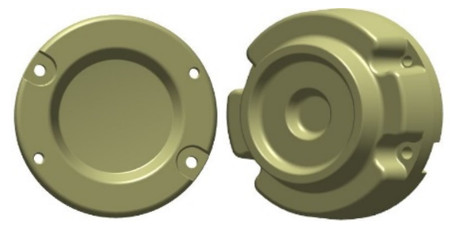

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

Rear Wheels and Tires

Tire chains on X300 Tire

Tire chains on X300 Tire

Overview

Tire chains provide added traction in snowy and icy conditions.

Additional details

- Roadmaster tire chains have a single cross-chain design that runs across the tire (resembles a ladder) and is used for on-road and off-road conditions

- Duo Grip tire chains have a dual cross chain design that forms an “H pattern” and is suited specifically for off-road conditions

Three-Point Hitch

LP25001 3pt hitch receiver hitch shown

LP25001 3pt hitch receiver hitch shown

Overview

Move trailers and other wheeled implements easily with the 3-point receiver hitch.

Benefits

- Easily move trailers and other wheeled implements

- Accepts standard 2-inch receivers ball mounts

- Compatible with CAT 1 IMatch Quick Hitch or and CAT 1 3pt tractor hitch

Magnetic hitch pin

Magnetic hitch pin

Fits John Deere lawn and garden tow behind attachments.

- Strong magnetic grip

- Rust resistant

- Easy to install, secure fit

Ordering information

Customers, please contact your local John Deere dealer for availability and pricing information.

Magnetic hitch pin

Order number: LP63768

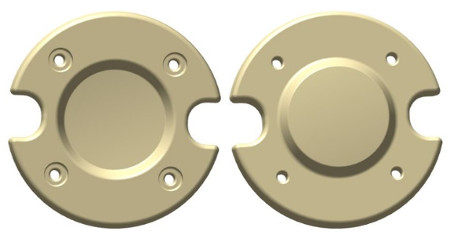

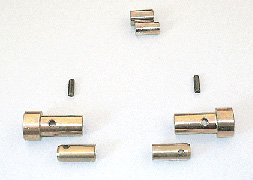

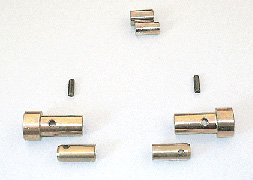

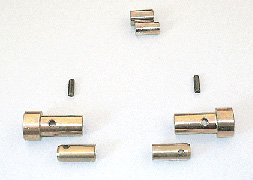

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

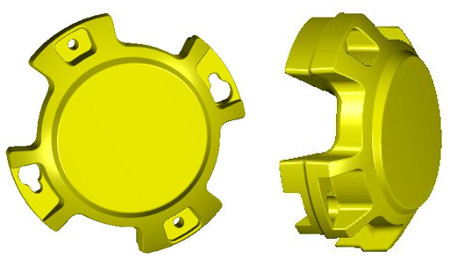

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

One of the greatest customer concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: In the picture above, you see the bushing set. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 0.76-0.77 in.

- Outside diameter: 1.24-1.25 in.

- Lower bushings

- Inside diameter: 0.88 to 0.89 in.

- Outside diameter: 1.43 to 1.44 in.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

Reviews

Location: ohio

Length of Ownership: 1yearOrLonger

Usage: Weekly

I have had a 650 with extratrak tires that i bought new over 30 years ago. always able to get it out of the mud and difficult areas. 4 wheel drive and able to lock both back tires when it go bad. the 2032 is not like that. going up a gentle slope in the snow, in "4 wheel drive" i had one front wheel turning and one back wheel turning. have been very nearly stuck multiple times. with out being able to have positive traction which i asked for and was told it had when i bought the tractor. It is a good tractor so far, just don't use it in the mud, snow, soft ground. or on a hill.

Location: Napoleon, Ohio

Length of Ownership: 1yearOrLonger

Usage: Weekly

I "upgraded" from a 2001 4110 FEL and 60" belly mower. It was a lighter tractor and mowed exceptionally well designed loader. I purchased the re-designed 2018 2032R with an FEL and 60" mower. The features on this tractor with the AutoConnect mower deck are light years beyond the competition and have gotten even better in 2022 with the self leveling loader and newly available 3rd function. As the non-self leveling loader is absolute rubbish in design and function, I'd highly recommend the self leveling model just because there is no way it could be worse than the 220R! The loader cylinder geometry renders bucket control to a rattling clunky affair that you cannot keep level to the ground you are working. My loader lacks the lift capacity of the old 4110. Get the fast coupler option for the loader as well. The 4 separate Pioneer connectors are poorly mounted, hard to couple, and undersized. The tractor could certainly benefit from more hydraulic gpm's. The front axle is a carryover from the miserable performing 4200 from the 90's. It won't turn as tight as a 3R series and will scuff on all but the driest of lawns. I wish the deck lift were hydraulic instead of hydraulic. The electric affair has already died on me once (warranty thank God).If they would update the 3R series with the available options on the 2R that would be a better option. You cannot believe how easy to use and pleasant this tractor is! The loader is just worthless.

Location: fairbanks Alaska

Length of Ownership: 1week

Usage: Daily

I have had this tractor for a week now, and have used it daily. This was a replacement unit for my Kubota B2650. The performance seems great. A few little things I don't care for include the placement of the key, and the lack of room around the differential lock. The lock, the 4wd selector, and the parking brake are close together, and there is insufficient room when wearing snow boots. I can live with these things, and the hydrostatic transmission is much quieter than the Kubota.

Location: Greenville NC

Length of Ownership: 1yearOrLonger

Usage: Daily

I bought this tractor in 2014 and now have over 1400 hours of operation on it. It is a high quality product, remarkable engine and hydraulics, and very powerful for its size. I mow about 7 acres a week with a 6 foot finishing mower. I also have a belly mower but opted out for a 3-pt hitch finish mower last year because of the terrain I mow. Both mowers worked great, but I prefer the 3-pt hitch mower for ease of removal and hookup since I also use the tractor for garden work. It handles a 5 ft tiller with ease, and all other rear implements as well. I recommend it highly and my next purchase will be another John Deere, . . . perhaps one with an air conditioned cab.

Location: wisconsin

Length of Ownership: 6months

Usage: Weekly

After a lot of research and talking to individuals with small acreages to contractors that use small tractors for landscaping work, I purchased a 2020 JD 2032R. Every guy that makes a living with small tractors recommended buying a John Deere if I could afford it. When I got a price for a comparable Kubota (not a stripped down Kubota), the JD 2032R was $50 more than the lowest JD dealer. JD dealers do vary a lot in price so shop around. The layout of the controls and the features built into the JD reflect a lot of refinement over older JD tractors and everything else on market. The FEL and mower detachment/attachment are amazingly well designed features. I immediate put my tractor into heavy use and over loaded the 220 FEL moving pallets of bricks. The 2032 repeatedly picked up in excess of its rated capacity and my contractor told me his orange tractor is lucky to lift 80% of its rating. The rest of the experience with the unit has been the same. Performing better than I expected. Mowing with the electric 60" deck is a premium experience and the tractor did not even notice running a 60" tiller through sod. Of special note, the emission regen system works perfectly and this is not a small matter. Many tractors with orange paint are failing to regenerate and spending a lot of time at the dealership rather than working for the owner. With the Deere, you just use it and the harder you work it, the better. The tractor takes care of the rest. The only real negative is this tractor is heavy and it leaves prints in my house yard after a good rain. I did buy a small rider for around the house to keep my wife happy. For mowing large areas, the 2032R is excellent. One caution is do not let your wife use it. My wife thinks its her tractor now.

Pros:

- serious equipment that exceeds its ratings

- easy to use fel and mower deck

- well laid out controls

- emission regen works without intervention

- easy to operate

Cons:

- heavy for mowing on wet ground

Location: Ok

Length of Ownership: 3months

Usage: Weekly

New to using tractors I Like this one cause of the ergonomics paid all cash for it and all attachments. 33k I believe. Human error on using imatch and bushings I didn’t need. Just great all round Just need a grapple. I went with John Deere attachments cause I just wanted to make sure it fits. They are a bit over priced but John Deere service is the greatest. On explanation and repairing etc. It took them forever to get some of my attachments during lock down of 2020 coronavirus. But got them all. Still learning all the ins and out but I love it. I match was a bit tricky but I think I had wrong bushings

Pros:

- best trac all around

Cons:

- the manuals are a bit difficult for beginners

Location: Jefferson, mD

Length of Ownership: 1yearOrLonger

Usage: Monthly

I got a 2032R 4 years ago and it is going strong, not a single problem yet. I have about 150 hrs on it, and it is a fantastic piece of equipment to have around our home (9 acre property).

Location: Lebanon

Length of Ownership: 1yearOrLonger

Usage: Weekly

I've owned this tractor new for 4 years and it has always been kept in a nice clean shop. It has 60 hours and have already had to replace the instrument panel due to the PTO kicking out after being on for 20 seconds, I've always been a big JD fan. I believe after this I'll probably be looking at other brands.

Cons:

- a lot of the parts are made in china

Location: Butler, PA

Length of Ownership: 1yearOrLonger

Usage: Weekly

First let me start off by saying.. My nearly 2 year old son's room is Green, he is getting a green electric tractor for his bday. Green was the only choice when I looked at tractors . I currently have 160 hours on machine and it is at the dealer for the 4th time. Bearing and seal for pto, hydraulic pump, some sort of valve... and now who knows.. I loathe it to the point I won't buy attachments for it because it makes me ill running the FEL with all the hydraulic noises it makes that it shouldn't. I've been able to steer other people away from this unit please do ur self a favor and stay away. I'm not saying John deere is bad, heck I even offered to trade it in and buy up but apparently it depreciated astronomically in 2 years.. I think around 40%. (I have babied this thing the only nights it has spent outside was in the dealership parking lot always washed greased, and properly operated) I Don't buy this tractor buy something else. I'm a forestry equipment operator of 15 years. I've ran 30 year old pieces of equipment, and equipment with the plastic still on the seats.

Pros:

- fel connects fast and easy

- mower deck is easy to connect

Cons:

- paints don't match between panels

- unrealiable

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By