315SL

Backhoe

- Net Peak Power: 77 kW (103 hp) at 1,600 rpm

- Max Standard Dipperstick Digging Depth: 4.08 m (13 ft. 5 in.)

- Operating Weight: 7 962 kg (17,554 lb.)

Compare to Competitors

Features

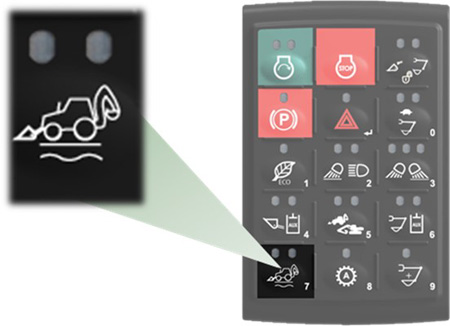

Auto ride control

Auto ride control

Overview

Auto ride control is based on an adjustable ground speed setting. When the set ground speed is reached, ride control will be turned on, creating a smoother ride for the operator and reducing spillage from the bucket. When the machine drops below the speed setting, ride control will be turned off, allowing for maximum productivity with the loader. Auto ride control is now the only ride-control option. This option eliminates the need to manually turn the feature on and off during load and carry applications, boosting operator ease of use.

Benefits

- When activated, front loader cylinders function as a shock absorber, smoothing the ride over rough terrain and reducing material spillage

- On/Off functionality is controlled by ground speed and can be adjusted by the operator in the cab’s display monitor

Additional Details

Increase productivity with the auto ride control field kit.

Increase productivity with the auto ride control field kit.

- Speed selectable in monitor

- Turns on ride control when ground speed exceeds setting in monitor

- Turns off ride control when ground speed drops below adjustable setting

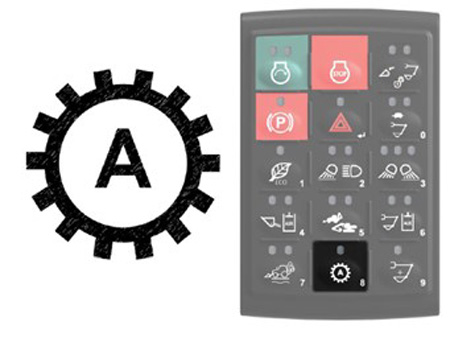

AutoShift Transmission

AutoShift Transmission

AutoShift allows the operator to be more productive by keeping the unit operating at its peak performance. When enabled on the sealed-switch module (SSM), AutoShift automatically shifts the PowerShift™ transmission to the appropriate gear, enhancing the operator experience. Simply set the control lever to the highest gear desired, and the transmission will optimally shift based on engine rpm and ground speed.

- The transmission will optimally shift based on engine rpm and ground speed

- Improves the operator experience during transport or load and carry applications.

- Smoothest shifting automatic transmission in the industry

- Improves operator comfort by reducing the number of times the transmission control lever (TCL) needs to be actuated during Loader operation

Overview

Standard economy mode can be configured separately between loader and backhoe functions. Activate economy mode for backhoe functions while retaining full power for loader functions. This helps maximize fuel usage in lighter-work applications with minimal effect on machine performance.

Benefits

- Quick and easy fuel savings are available at the push of a button.

- Economy mode SSM push button activation for reduced fuel consumption

- Economy mode is still available on the monitor on non-SSM machines.

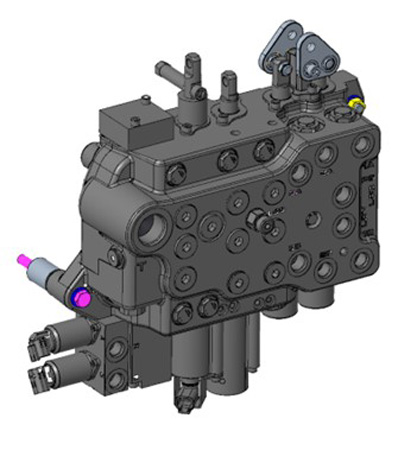

Loader-control valve

Loader-control valve

Overview

The loader control valve has been redesigned. The new valve will help reduce hydraulic cylinder-rod drift, improve metering profiles and controllability, and boost three-point stance performance. The auxiliary flow has been increased by 5 gpm (19 L/min) for improved performance on high flow loader attachments.

Benefits

- Updated to reduce hydraulic cylinder-rod drift and improve metering profiles and controllability

- Integrated, low-leak, check valves in loader boom and bucket rod circuits, improving three-point stance performance

- Electrohydraulic (EH) auxiliary hydraulics are now integrated into the valve body, for minimized connections and potential leak points.

- Maximum auxiliary flow has increased to 35 gpm (133 L/min), for improved performance of high-flow loader attachments.

- Reduced spool to bore leakage

- Anti-cavitation standard on boom and bucket to further help with back dragging applications

Loader-lever linkage

Loader-lever linkage

- Greaseless Bucket Cylinder to Guide Link Pin

- Retained Pin in Guide Link to Lift Arm Joint

Improved loader lever control grip

Improved loader lever control grip

Overview

Enhanced “palm-on-top” loader-control grip is comfortable and easy to use. The loader-control valve has been redesigned to reduce resistance and improve its throw and feel.

Benefits

- Lever travel from handle-to-linkage ratio has been reduced up to 15 percent.

- Update includes removal of the spherical joint and replacement with a forged U-joint and integrated needle bearings, for maximized durability.

- Maintains same loader grip and harness as previous L-Series Backhoes.

315SL with powered sideshift option

315SL with powered sideshift option

Overview

The operator can now easily unlock and shift the 315SL along the H-frame using a single combination in-cab switch located on the main control panel. This eliminates the risk of damaging streets, parking lots, or other terrain when manually shifting the backhoe with the rear bucket.

Benefits

- Side-to-side cycle is completed in under six seconds

- Includes a series of two hydraulic cylinders used to smoothly shift the backhoe, the design eliminates the need for a chain-drive or pulley system

- Bronze wear pads are used on the H-frame to reduce friction and improve the durability and wear life of the slide rail

- Feature enables offset digging for improved visibility to the trench

Additional Details

315SL sideshift backhoe trenching next to a wall

315SL sideshift backhoe trenching next to a wall

- The powered sideshift option allows operators to take full advantage of the 315SL’s narrow footprint with vertical stabilizers

- Sideshift backhoes are particularly valued in applications such as street repair; underground utility work in congested urban areas; constructing square trench boxes; and digging next to buildings, walls, or other structures

John Deere PowerTech™ engine

John Deere PowerTech™ engine

Overview

The engine has been updated to the John Deere PowerTech™ EWL that eliminates the diesel particulate filter (DPF) and exhaust gas recirculation (EGR) system. Underground customers will appreciate the increased power, improved torque, and greater reliability compared to the previous design.

- EPA Final Tier 4 (FT4)/EU Stage IV emission certified.

- 3–7 power net horsepower increase with improved torque curve.

- Removal of the exhaust gas recirculation (EGR) system and components (plumbing, cooler, and sensors).

- Simpler two-valve cylinder-head design.

- Redesigned and improved fuel-filter location enables easy access when changing filters.

- No DPF, reducing maintenance costs on the aftertreatment system.

Final Tier 4 has added a selective catalyst reduction (SCR) system

Final Tier 4 has added a selective catalyst reduction (SCR) system

- To further reduce NOx, diesel exhaust fluid (DEF) is injected into the exhaust stream, where it decomposes into ammonia (NH3).

- Nitrogen oxides react with the ammonia in an SCR canister consisting of an SCR catalyst and ammonia oxidation catalyst.

- This reaction forms harmless nitrogen gas and water vapor, which are expelled through the exhaust pipe.

Ground level serviceability

Ground level serviceability

Overview

Check and change fluids quickly and cleanly from the ground to keep equipment running smoothly. Separating coolers is quick and easy. Worry less about contaminants and moisture entering the axle case and shortening the life of your oil and axle components.

Benefits

- Same side, ground level daily service – including fuel fill; easy checks are more likely to get done, preventing a major failure, and reducing inspection time

- Two position easy tilt hood

- Hinged Cooling Package Design

- Fully sealed front and rear axles

Additional Details

Angled and sloped hood

Angled and sloped hood

The one-piece SLX engine hood is constructed of a durable, paint-less plastic hood process. The hood retains the 2-position functionality for easy daily service checks and outstanding accessibility to the engine and cooling package with the loader boom raised and locked in position.

- Angled and sloped hood provides improved visibility to front loader and forks

- Integrates color into the molding process, eliminating the need for exterior paint Reduces visible surface scratches

- Improves hood alignment with mounting saddle and latching Minimizes flexing with reinforcement at the pivot and sides

Specs & Compare

DRIVELINE | 315SL Current Model |

| Engine Manufacturer | John Deere |

| Engine Model | PowerTech EWL 4045HL050 |

| Displacement, ltr (Inches³) | 4.5 (276) |

| Rated Speed, rpm | 1600 |

| Engine Output - Net, kW (hp) | 77 (103) |

| Transmission Type | Power Shift |

| Service Brake Type | Wet Multi Disc |

| Service Brake Actuation | Hydraulic w/Power Assist |

DIMENSIONS | |

| Max length with std. Stick, mm (ft/in) | 5960 (19 ft 7 in) |

| Max length with ext. Stick, mm (ft/in) | 5960 (19 ft 7 in) |

| Height over std Stick, mm (ft/in) | 3710 (12 ft 2 in) |

| Height over ext Stick, mm (ft/in) | 3710 (12 ft 2 in) |

| Maximum Width, mm (ft/in) | 2430 (8 ft ) |

| Width over tires, mm (ft/in) | 2260 (7 ft 5 in) |

| Wheelbase - 4WD, mm (ft/in) | 2190 (7 ft 2 in) |

| Ground Clearance, mm (inches) | 351 (14) |

| Width - General Purpose Bucket, mm (ft/in) | 2184 (7 ft 2 in) - HD |

| Bucket Rotation - Position 1, Degrees | 190 |

| Bucket Pin Height - General Purpose, mm (ft/in) | 3450 (11 ft 4 in) |

| Dump Height - General Purpose, mm (ft/in) | 2750 (9 ft ) - HD |

| Dump Reach - General Purpose, mm (inches) | 743 (29.2) - HD |

| Digging Depth - General Purpose, mm (inches) | 89 (3.5) - HD |

CAPACITIES | |

| Fuel Tank, ltr (gallons (US)) | 128.7 (34) |

| Hydraulic Tank, ltr (gallons (US)) | 45 (11.9) |

| Rear Axle, ltr (gallons (US)) | 18 (4.75) |

| 4WD Front Axle, ltr (gallons (US)) | 6.5 (1.725) |

| Capacity Heaped - Bucket 1, m³ (ft³) | 0.21 (7.5) |

| Bucket Capacity - Standard General Purpose, m³ (yd³) | 0.77 (1) |

| Battery Voltage, V | 12 |

| Bucket Tearout - Non-Extending Dipper, kN (lbf) | 55 (12361) |

| Stick tearout, kN (lbf) | 36.6 (8231) |

| Boom Lift - Maximum Reach - Non-Extending Dipper, kg (lbs) | 1744 (3846) |

| Bucket Breakout - General Purpose, kN (lbf) | 49.2 (11060) |

| Lift To Full Height - General Purpose Bucket, kg (lbs) | 3456 (7619) |

| Pump | Gear Pump - Tandem |

| Pump Flow, lt/min (gallons (US) / min) | 136 (36) |

WEIGHTS | |

| Operating Weight, kg (lbs) | 8182 (18038) |

| Weight - 4WD, GP, std Stick, kg (lbs) | 8182 (18038) |

Offers & Discounts

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By