5075M

Utility Tractor

- PowrReverser™ 16F/16R and 32F/16R Hi-Lo transmission options

- Choose climate-controlled cab or open station

- Hitch lift capacity of 5,150 lb (2,336 kg) with an option of 5,950 lb (2,699 kg)

View Product Brochure

Features

5M Tractor Premium Cab with panorama roof

5M Tractor Premium Cab with panorama roof

Overview

Experience ultimate operator experience in comfort and convenience by upgrading to the Premium Cab on 5M tractors. Upgrading to the Premium Cab unlocks a fixed panorama roof ideal for loader work.

Benefits

- Improve upward visibility by 80 percent vs standard cab for easier bale stacking, pallet stacking, and dumping loads into walled trailers with the panorama roof

- Additional storage space with the rear floor mat behind the seat

- Excellent visibility to rear operations with the rearview mirror

- Shield the operator from the sun with an easy-to-use front sunshade

Features |

Standard Cab |

Premium Panorama Roof Cab |

Deluxe isolated cab with flat floor |

X |

X |

Tilt and telescopic steering column |

X |

X |

Convenience power outlet |

X |

X |

Air conditioning and heater |

X |

X |

Speedometer |

X |

X |

Beverage Holder |

X |

X |

Sun visor for front window |

X |

X |

Two-speed front windshield wiper and washer |

X |

X |

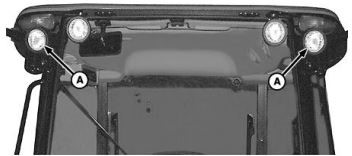

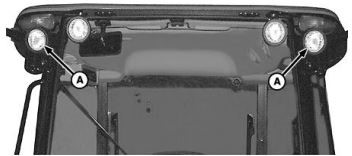

Two front/two rear roof-mounted worklights |

X |

X |

Two front/two rear roof-mounted warning lights |

X |

X |

Two fender-mounted taillights |

X |

X |

120Amp Alternator |

X |

X |

Convenience power outlet |

X |

X |

Monitor mounting bosses (two Sets) |

X |

X |

Swing-out rear window with two removable rear plugs for monitor |

X |

X |

Right-hand console light |

X |

X |

Radio preparation (with speakers, wiring) |

X |

X |

Rear window grab handle |

X |

X |

Bluetooth® ready |

X |

X |

Requires option code 3025 (Deluxe cornerpost exhaust). |

X |

X |

Fixed panorama roof with shade |

- |

X |

Radio (Bluetooth® and Satellite Capable) |

- |

X |

Rear window wiper |

Option |

X |

Radio antenna |

- |

X |

Requires option code 4030 (ElectroHydraulic (EH) rear hitch) |

- |

X |

Requires option code 6040 (MFWD) |

- |

X |

Bluetooth is a trademark of Bluetooth SIG, Inc.

Instrument cluster

Instrument cluster

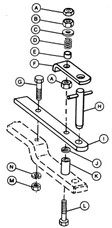

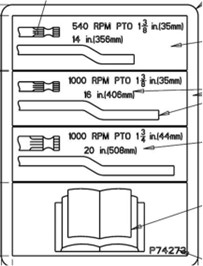

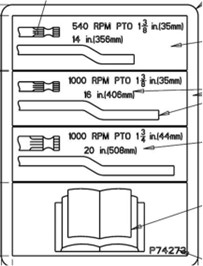

Power take-off (PTO) target bars

Power take-off (PTO) target bars

Overview

Operators can view information in a crisp, vibrant, and useful array on the tractor instrument cluster.

Benefits

- Clear and bright indicators, warning lights, and gauges

- Provides operators with crucial onboard diagnostics through the roll-mode function

- Visibility of engine hours, ground speed, Hi-Lo indicator, forward, neutral, and reverse all at the same time

- Light-out indicator for trailer light, turn light, and hazard light bulbs

- Clearly presented PTO target bars to indicate the correct PTO speeds when operating the PTO

Additional details

There are daytime and nighttime modes which are based on the position of the light switch. The mode adjusts the backlight levels of the display for optimum visibility.

Overview

Ample speeds and ease of operation for demanding applications with the 16F/16R PowrReverser, providing 16 forward speeds and 16 reverse speeds. This transmission comes standard with a dual speed 540/540 Economy power take-off (PTO), and it is ideal for applications requiring frequent directional changes, such as loader work.

Benefits

- Effortlessly switch directions with a small finger motion using the electrohydraulic fingertip directional lever

- Frees the right hand to operate other tractor controls, such as the loader, rear implements, or throttle, as the directional lever allows the operator to steer and shift direction with the left hand

- Ideal for rear blading and any applications that require frequent directional changes in tight spaces

- Clutch-less hydraulic shifting between forward and reverse

- Lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort from the standard economy PTO (E-PTO)

Additional details

16F/16R transmission includes:

- Hydraulic wet clutches (forward and reverse)

- Maximize durability and outlast the life of any dry clutch

- When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs

- Platform-mounted shift levers (four ranges, four gears)

- Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience

- The gear-shift lever is easy to reach, and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two

- Left-hand reverser

- The control is located on the left side of the steering column and selects forward, reverse, and neutral positions

- Constant-mesh helical-cut gears

- Provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability

- Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating

- Pressure-lubricated top shaft

- Positive park pawl: provides positive park and eliminates the need for a hand brake

- Neutral start switch

Gear and range shift levers (cab)t

Gear and range shift levers (cab)t

Gear shift lever open operator’s station (OOS)

Gear shift lever open operator’s station (OOS)

Range shift lever (OOS)

Range shift lever (OOS)

The forward lever selects one of four speeds, all synchronized shifts for on-the-go shifting with the use of the clutch. The rear lever selects ranges A, B, C, or D. All ranges are fully synchronized. When upshifting, operators can move between ranges without stopping the tractor providing convenience for on-the-go shifting from field to transport.

Left-hand reverser lever

Left-hand reverser lever

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

Integrated declutch button on gear shifter

Integrated declutch button on gear shifter

NOTE: The PowrReverser transmission is not available for the 5130M or 5130ML tractors.

The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

See the PTO functional area for more information on E-PTO.

Creeper lever on 5MH only

Creeper lever on 5MH only

The creeper gears are accessible by engaging the creeper lever into rabbit or turtle position. This provides 2 additional slow working ranges perfect for bedded crops.

See the PTO functional area for more information on E-PTO.

Hi-Lo selector on gear lever

Hi-Lo selector on gear lever

Overview

For operators requiring more field speeds to achieve the most precise operating ranges, as well as for quickly moving from task to task with transport speeds of up to 40.23 km/h (25 mph), the PowrReverser™ Hi-Lo 32F/16R transmission is the ideal choice. This transmission provides 32F/16R speeds for the ultimate in speed selection.

Benefits

- Effortlessly switch directions with a small finger motion using the electrohydraulic fingertip directional lever

- Frees the right hand to operate other tractor controls, such as the loader, rear implements, or throttle, as the directional lever allows the operator to steer and shift direction with the left hand

- The control is located on the left side of the instrument console and selects forward, reverse, and neutral positions

- Clutch-less hydraulic shifting between forward and reverse

- Convenient push-button controls actuate the electrohydraulic hi-lo selector providing an extra 20% increase/decrease in speed for each forward gear

- Lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort from the standard economy PTO (E-PTO)

Additional details

32F/16R transmission includes:

- Hydraulic wet clutches (forward and reverse)

- Maximize durability and outlast the life of any dry clutch

- When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs

- Platform-mounted shift levers (four gears, four ranges)

- Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience

- The gear-shift lever is easy to reach, and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two

- Left-hand reverser

- Constant-mesh helical-cut gears

- Provide quieter operation and excellent reliability while the pressure-lubricated top shaft adds to the transmission durability

- Fully enclosed, rigid shift linkages for short throw and crisp shifts enable all operators to clearly know in what range and gear they are operating

- Pressure-lubricated top shaft

- Positive park pawl: provides positive park and eliminates the need for a hand brake

- Neutral start switch

The gear lever selects one of four speeds, all synchronized shifts for on-the-go shifting with the use of the clutch. This same lever is where the hi-lo control buttons are located which provide a single shift up/down in speed within each forward range. The rear lever selects ranges A, B, C, or D. All ranges are fully synchronized which means, when shifting, operators can move between any range A-D without stopping the tractor.

The hi-lo feature benefits operators who frequently transport their tractors from field to field or find themselves in bog-down situations during rear power take-off (PTO) work such as baling in variable sized windrows. Customers can push the rabbit button (high) without having to depress the clutch to get a 20 percent increase in speed. They can also push the turtle button (low) to get a 20 percent decrease in speed, similar to downshifting or engine braking without having to grab another gear.

Shuttle control knob

Shuttle control knob

The 32F/16R transmission includes the infinitely variable shuttle control feature allowing fine-tuning of the speed of directional changes to the operator's preference or application demands. This dial adjusts the aggressiveness of the tractor’s directional change. Some prefer a quicker more precise change, whereas other operators are more comfortable with a slow roll out before moving in the opposite direction. This feature can be significant for precision work with pallet forks or changing to bale stacking applications.

The PowrReverser™ has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine. NOTE: See PTO detailed feature for more information on E-PTO.

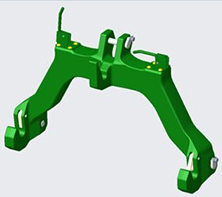

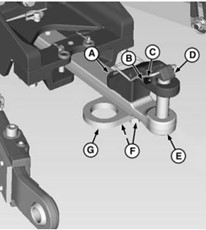

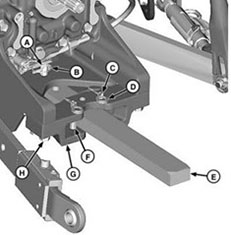

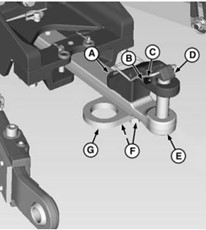

5M Tractor 3-point hitch

5M Tractor 3-point hitch

Overview

Heavy-duty 3-point hitch provides lift capacity and adjustability for implement versatility with Category 2 implements or adaptable to Category 1. Precisely raise and lower heavy implements such as planters, sprayers, and field cultivators, using the rockshaft control lever. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop.

Benefits

- Convenience hooking up implements with telescoping draft links, adjustable sway bars, and interchangeable hitch balls with the choice of either mechanical or electrohydraulic controls.

- Consistency when lowering hitch with depth stop on both mechanical and electrohydraulic hitch controls - each time the position control lever is pushed forward, it stops where the depth stop has been positioned. Useful when preparing a seedbed.

- Compatible with implements needed to perform multiple jobs. Increased lift capacity is available with optional larger cylinders. See Specifications for lift capacity by model.

- Convenience when leveling implements with right lift link being able to adjust without tools - lift links can be adjusted for lateral float to allow implements with gauge wheels or skids to follow the ground contour

Additional details

Mechanical or electrohydraulic hitch control operation

Raise and lower rear implements with precision with either the mechanical or electrohydraulic (EH) hitch control. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop.

The mechanical hitch control is paired with the tractors equipped with a PowrReverser™ transmission while the EH hitch control is paired with units equipped with a PowrQuad™ PLUS or Powr8™ transmission. Both control types enable the operator to adjust the speed at which an implement can be lowered by adjusting the rockshaft rate of drop. In addition to this feature, the EH hitch control adds repeatable movements by enabling the operator to set both an upper and lower limit.

The adjustable depth stop (found on both control types) provides consistency when lowering the hitch. Each time the position control lever is pushed forward, it stops where the depth stop has been positioned. This feature is a value to anyone who desires a consistent, level ground, like when preparing a seedbed.

The center link can be set in one of three positions to accurately set the implement position and draft sensing. The right lift link is adjustable without tools for added convenience when leveling implements.

Optional larger cylinders:

Transmission |

Cylinder diameter |

Lift capacity at 610-mm (24-in) behind lift point |

PowrReverser™ transmission models |

Two 65-mm (2.56-in.) cylinders |

See specifications for lift capacity. |

PowrReverser models with optional high-capacity hitch |

One 65-mm (2.56-in.) cylinder |

|

PowrQuad PLUS or Powr8 transmission models |

Two 75-mm (2.95-in.) cylinders |

|

PowrQuad PLUS or Powr8 models with optional high-capacity hitch |

Two 80-mm (3.15-in.) cylinders |

Rear fender hitch controls

5M rear fender hitch controls

5M rear fender hitch controls

Operators do not need to carry a tool to adjust the rear hitch. Operators can also raise and lower the 3-point hitch from outside of the tractor with the conveniently located rear fender hitch controls.

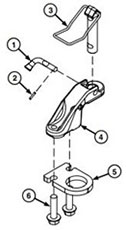

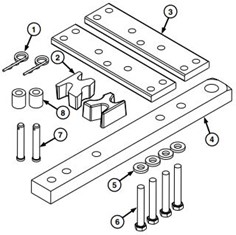

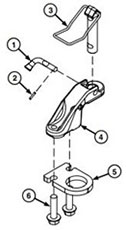

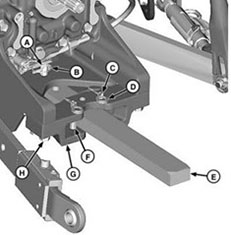

Rear quick hitch

Rear quick hitch

Rear quick hitch

Sideview of quick hitch shown on 5M

Sideview of quick hitch shown on 5M

An updated three-point quick hitch is offered on the 5M Tractors.

- This updated design is a break from the existing welded quick hitch as the frame is cast.

- The curved design eliminates the potential for contact with the rear fender and extensions.

- The quick hitch is available as a field kit option.

Sway bars

5M Tractor sway bars

5M Tractor sway bars

Adjustable sway bars and telescoping draft links can be easily adjusted to adapt to a wide variety of implements. The right lift link also adjusts without tools for added convenience when leveling implements.

The engine powering the 5075M is EPA certified Tier Level 4. This is achieved through a combination of a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF). John Deere uses the most efficient solution for the tractor package to meet emissions requirements at each horsepower level. The system always defaults to passive regeneration mode, and will only go into an active regeneration cycle when necessary without impacting engine performance. This active cycle takes place on average about every 40 hours of normal tractor operation. The regeneration process cleans out the DPF element.

Model |

Cylinders |

Engine displacement |

Engine hp |

PTO hp |

Rated rpm |

Aspiration |

5075M |

3 |

2.9 L (0.77 gal.) |

75 |

57.6 |

2400 |

Turbocharged |

As per 97/68/EC ISO at rated speed.

Other key engine features and related benefits:

- Heavy-duty cylinder block – strength and rigidity

- Balanced crankshaft – reduces engine vibration

- Optimized cylinder heads – improved airflow, better fuel economy

- Low friction, high-ring pistons – cast-aluminum design

- Plasma-coated top rings – reduced drag on cylinder wall

- Wet-type cylinder liners – dissipate heat to prevent cylinder wear

- Full-pressure lubrication system – eliminates excessive heat

- Electric fuel shutoff – does not allow bypass starting

Torque

When the tractor is under load, power bulge and torque rise work together to get through the tough spots. Horsepower and torque are mathematically related.

|

Power through tough spots

Power through tough spots

Benefits of torque reserve:

- Improved fuel efficiency

- Reduced noise levels

- Less downshifting

- Increased productivity

- Efficient throttle response

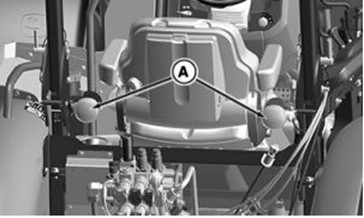

Tractor weight package

Tractor weight package

Overview

Keep implements in the ground with more down force that comes from a heavy tractor. The compactness of the 5M Series regarding wheelbase, weight, and total height tractor makes this tractor suited for a variety of different applications and is the perfect choice for all types of farms.

Benefits

- Improved traction and performance in the field

- Ability to power through tough jobs with heavy and durable cast steel

- Better stability when performing loader work

- Transport full bucket loads faster and lift bales higher with a stronger and more stable base

Additional details

See specifications for machine weight.

Specs & Compare

Key Specs | 5075M Current Model |

| Engine description | John Deere Deere PowerTech™ 3029 EWX |

| Engine displacement | 3 cylinder: 2.9 L 179 cu in. |

| Rated engine power | At 2200 rpm per ISO 97/68/EC: 55.1 kW 73.9 hp |

| Maximum engine power | 55.1 kW 73.9 hp |

| Rated PTO power (hp SAE) | At 2100 rpm per SAE: 43 kW 57.7 PTO hp |

| Maximum PTO power | |

| Transmission type | Standard: PowrReverser™ 16F/16R Optional: PowrReverser Hi-Lo 32F/16R |

| Hydraulic pump rated output | Standard: 94 L/min 24.7 gpm |

| Rear hitch category (SAE designation) | Category 2; convertible to 1 |

| Base machine weight | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Engine specifications | |

| Description | John Deere PowerTech™ 3029 EWX |

| Engine type | 3029HPY96 |

| Engine family | NJDXL02.9318 |

| Rated speed | 2200 rpm |

| Aspiration | Turbocharged and air-to-air aftercooled |

| Cylinders liners | Wet sleeved |

| Emission level | Final Tier 4 |

| After treatment type | DOC/DPF |

| Displacement | 3 cylinder: 2.9 L 179 cu in. |

Engine performance | |

| Rated power | At 2200 rpm per ISO 97/68/EC: 55.1 kW 73.9 hp |

| Rated PTO power (hp SAE) | At 2100 rpm per SAE: 43 kW 57.7 PTO hp |

| Maximum PTO power | |

| Intelligent Power Management (IPM) | |

| Power boost | 0 percent |

| Maximum engine power | 55.1 kW 73.9 hp |

| Engine peak torque | At 1600 rpm: 300 Nm 221 lb-ft |

| Drawbar power | |

| PTO torque rise | At 1400 rpm: 26 percent |

| Fuel injection system and control | |

| Air cleaner type | |

| Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628) | |

| Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628) | |

Transmission | |

| Type | Standard: PowrReverser™ 16F/16R Optional: PowrReverser Hi-Lo 32F/16R |

| Reverser | Left hand, electrohydraulic |

| Clutch; wet/dry | Wet |

| Creeper | Not available |

Hydraulic system | |

| Type | Open center |

| Pump rated output | 94 L/min 24.7 gpm |

| Available flow at a single rear SCV | 70 L/min 18.4 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | Two, up to three total |

| Number of mid selective control valves (SCVs) | Two, up to three total |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | Optional |

| Auxiliary hydraulic features | |

| SCV control | Mechanical |

Rear hitch | |

| Hitch draft control load sense type | Mechanical or electrohydraulic |

| Remote control valves available | Standard: 2 Optional: 3 |

| Hitch category (SAE designation) | Category 2; convertible to 1 |

| Maximum lift capacity behind lift points | Standard: 2336 kg 5150 lb Optional: 2699 kg 5950 lb |

| Lift capacity at standard frame | |

| Sensing type | Lower link |

| Rear axle differential lock | Electrohydraulic |

Drawbar | |

| Drawbar category | Category 2 |

| Maximum vertical load | Road/field use (250-mm extended): 1450 kg 3197 lb Field use (350-mm extended): 1200 kg 2646 lb Field use (400-mm extended): 1200 kg 2646 lb |

Rear power take-off (PTO) | |

| Type | Independent, 34.9 mm (1.375 in) Standard: 540/540 Economy (6 spline) Optional: 540/540E (6 spline) and 1000 rpm (21 spline) reversible shaft |

| Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1645 rpm 1000 at 2100 rpm |

| Economy PTO speeds | |

| Reverse PTO speeds | |

| Multispeed PTO option availability | |

| Ground speed PTO option availability | |

| PTO actuation | Electrohydraulic |

Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

Rear axle | |

| Type | Flange |

| Final drive type | Inboard planetary |

| Differential controls | Electrohydraulic |

| Axle type | |

| Brakes, type and control | Hydraulic wet disc |

| Rear differential lock | |

| Load rating | |

Front axle | |

| Type | |

| Front axle differential lock | |

| Load rating | |

Tires | |

| Rear | 2WD: 460/85R30 (18.4R30) R1W Radial MFWD: 460/85R30 (18.4R30) R1W Radial |

| Wheel tread range | 2WD: front: 1520-2020 mm 59.8-79.5 in. rear: 1349-2055 mm 53.1-80.9 in. MFWD: front: 1299-1997 mm 51.1-78.6 in. |

| Turning radius with brakes | 2WD: 3.67 m 12.04 ft MFWD: 3.85 m 12.6 ft |

| Turning radius without brakes | 2WD: 3.85 m 12.6 ft MFWD: 4.0 m 13.1 ft |

| Central Tire Inflation System (CTIS) | |

| Front | |

Tracks | |

| Tread spacing | |

| Drive type | |

| Track width | |

| Mid-rollers | |

Steering | |

Brakes | |

| Primary brake (foot brake) | |

| Secondary brake | |

| Park lock | |

| MFWD braking | |

| Front axle brakes | |

| Auxiliary brakes | |

| Hydraulic trailer brakes | |

| Pneumatic trailer brakes | |

Electrical system | |

| Alternator size | OOS: 90 amp Cab: 120 amp |

| Battery options | 12 V |

| Working lights | Standard: Halogen Optional: LED |

| Type of bulb in headlight (Halogen, Zenon, LED) | Standard: Halogen Optional: LED |

| Type of bulb in beacon (Halogen, Zenon, LED) | Optional: LED |

| dB(A) rating for backup alarm | |

| Total cold cranking amps | |

Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, two-post Platform - flat/straddle Flat Gearshift location - console/floor Floor |

| Seat | Standard: Mechanical suspension Optional: air ride or premium air ride |

| Cab suspension | |

| Instructional seat | Optional |

| Display | Automotive-style light-emitting diode (LED) instrument cluster |

| Radio | Optional |

| Inner cab volume | |

| dB(A) rating | 78 dBA |

| Cab glass area | |

| Safety glass rating | |

| Front visibility | |

Dimensions | |

| Wheelbase | 2WD and MFWD: 2350 mm 92.5 in. |

| Overall width | |

| Overall length | |

| Overall height | |

| Drawbar clearance | |

| Front axle center | |

| Approximate shipping weight, Open;Cab | 2WD: Open: 3700 kg 8140 lb Cab: 3900 kg 8580 lb MFWD: Open: 3975 kg 8765 lb Cab: 4175 kg 9185 lb |

Weight | |

| Base machine weight | |

| Maximum ballast level | |

| Maximum permissible weight | |

Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard: Open: 148.4 L 39.2 U.S. gal. Cab: 165.4 L 43.7 U.S. gal. Optional: Open: 178.3 L 47.1 U.S. gal. Cab: 196.8 L 52 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | Not Applicable |

| Cooling system | |

| Transmission-hydraulic system | |

Serviceability | |

| Interval for engine oil change | |

| Interval for hydraulic/transmission oil change | |

| Interval for engine coolant change | |

Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Leveling type | |

Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

Miscellaneous | |

| AutoTrac ready | No |

| ISOBUS ready | No |

| CommandCenter video inputs | |

| Immobilizer | |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Country of manufacture | Pune, India |

Additional information | |

Offers & Discounts

Accessories & Attachments

Cab Operator's Station

Ashtray

Ashtray

Cigarette lighter

Cigarette lighter

Ashtray

Ashtray

Cigarette lighter

Cigarette lighter

Powerstrip in 5025 Series Cab Tractor

Powerstrip in 5025 Series Cab Tractor

A powerstrip provides the operator with an additional six outlets providing key-switched and unswitched power that works simply by rotating the position of the plug 180 degrees.

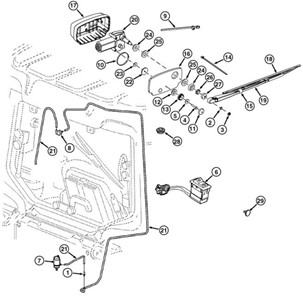

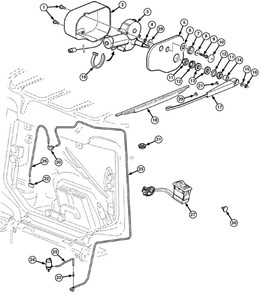

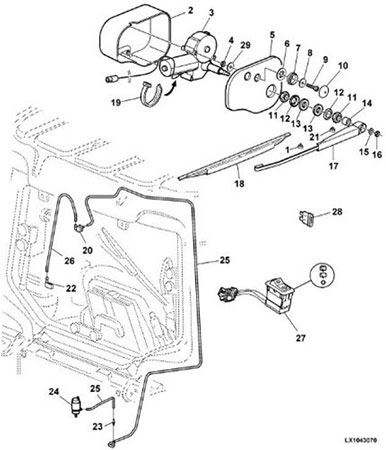

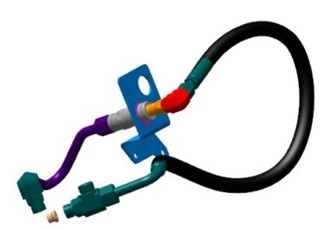

SJ16226 Rear Wiper Kit shown

SJ16226 Rear Wiper Kit shown

RE244873 Rear Wiper Kit shown

RE244873 Rear Wiper Kit shown

LG102380 Rear Wiper and Washer Kit shown

LG102380 Rear Wiper and Washer Kit shown

LV100113 Rear Wiper and Washer kit shown

LV100113 Rear Wiper and Washer kit shown

Overview

The rear wiper kit provides better rear visibility during inclement weather. It includes a wiper and a wiper nozzle that disperses fluid to clean the window.

A backrest extension improves operator comfort in cab and isolated open operator station tractors.

Custom key door locks

Custom key door lock kit

Custom key door lock kit

Field-installed kit (AL71345) allows for a door handle to be installed that has a key different from the tractor ignition key.

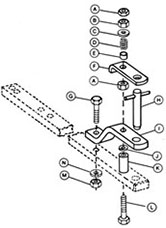

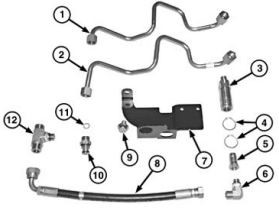

Drawbar

RE242110 Hammer Strap and Chain Clevis Kit shown

RE242110 Hammer Strap and Chain Clevis Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

BSJ10503 Air Trailer Brake Kit shown

BSJ10503 Air Trailer Brake Kit shown

RE39829 Drawbar Clevis Kit shown

RE39829 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

R196191 Drawbar shown

R196191 Drawbar shown

R133359 Drawbar shown

R133359 Drawbar shown

R197239 Drawbar shown

R197239 Drawbar shown

Overview

Drawbars, Hammer strap and chain clevis kits allow for operators to change the positioning of the drawbar based on operation being completed.

NOTE: Refer to owner’s manual for drawbar and PTO specifications

Straight drawbar clevis kit

Straight drawbar clevis kit

RE39830 offset drawbar clevis kit

RE39830 offset drawbar clevis kit

R133359 offset drawbar – standard duty

R133359 offset drawbar – standard duty

R197239 offset drawbar – heavy duty

R197239 offset drawbar – heavy duty

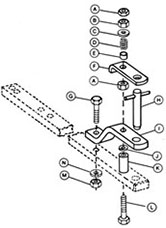

Overview

The RE39830 offset drawbar clevis kit is to be used in conjunction with either the R133359 standard-duty offset drawbar or R197239 heavy-duty offset drawbar to provide a 63.5-mm (2.5-in.) drop over a straight drawbar.

Please contact a dealer or refer to the operator’s manual for compatibility and determination of vertical load capacities specific to the standard and heavy-duty drawbars.

Straight drawbar clevis kit

Straight drawbar clevis kit

RE39830 offset drawbar clevis kit

RE39830 offset drawbar clevis kit

R133359 offset drawbar – standard duty

R133359 offset drawbar – standard duty

R197239 offset drawbar – heavy duty

R197239 offset drawbar – heavy duty

Overview

The RE39830 offset drawbar clevis kit is to be used in conjunction with either the R133359 standard-duty offset drawbar or R197239 heavy-duty offset drawbar to provide a 63.5-mm (2.5-in.) drop over a straight drawbar.

Please contact a dealer or refer to the operator’s manual for compatibility and determination of vertical load capacities specific to the standard and heavy-duty drawbars.

RE242110 Hammer Strap and Chain Clevis Kit shown

RE242110 Hammer Strap and Chain Clevis Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

RE275866 Heavy-Duty Drawbar Kit shown

BSJ10503 Air Trailer Brake Kit shown

BSJ10503 Air Trailer Brake Kit shown

RE39829 Drawbar Clevis Kit shown

RE39829 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

RE39830 Drawbar Clevis Kit shown

R196191 Drawbar shown

R196191 Drawbar shown

R133359 Drawbar shown

R133359 Drawbar shown

R197239 Drawbar shown

R197239 Drawbar shown

Overview

Drawbars, Hammer strap and chain clevis kits allow for operators to change the positioning of the drawbar based on operation being completed.

NOTE: Refer to owner’s manual for drawbar and PTO specifications

Straight drawbar clevis kit

Straight drawbar clevis kit

RE39830 offset drawbar clevis kit

RE39830 offset drawbar clevis kit

R133359 offset drawbar – standard duty

R133359 offset drawbar – standard duty

R197239 offset drawbar – heavy duty

R197239 offset drawbar – heavy duty

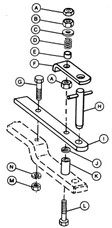

Overview

The RE39830 offset drawbar clevis kit is to be used in conjunction with either the R133359 standard-duty offset drawbar or R197239 heavy-duty offset drawbar to provide a 63.5-mm (2.5-in.) drop over a straight drawbar.

Please contact a dealer or refer to the operator’s manual for compatibility and determination of vertical load capacities specific to the standard and heavy-duty drawbars.

Safety chain support

Safety chain support

-

Provides necessary tractor parts to accept implement safety chains

-

Attaches to tractor drawbar ahead of hitch pin

-

Order safety chain from implement section

Front Fenders

Front fenders installed on a 5M Tractor

Front fenders installed on a 5M Tractor

Mechanical front-wheel drive (MFWD) front fenders protect operators and the 4WD tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The fenders are not compatible with loaders. LVB25776 mounting bracket and hardware kit must be ordered separately.

Front fenders installed on a 5M Tractor

Front fenders installed on a 5M Tractor

Mechanical front-wheel drive (MFWD) front fenders protect operators and the 4WD tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The fenders are not compatible with loaders. LVB25776 mounting bracket and hardware kit must be ordered separately.

Front fenders installed on a 5M Tractor

Front fenders installed on a 5M Tractor

Mechanical front-wheel drive (MFWD) front fenders protect operators and the 4WD tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The fenders are not compatible with loaders. LVB25776 mounting bracket and hardware kit must be ordered separately.

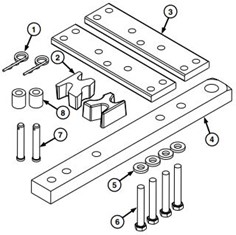

Front Weights

SU58373 front weight support for 20 suitcase weights

SU58373 front weight support for 20 suitcase weights

Overview

SU58373 is a cast-iron front weight support that allows for up to 20 suitcase weights to be added to the front of the tractor for proper ballasting.

The front weight support weighs 110 kg (242 lb) and has a 20-weight carrying capacity. Each front suitcase weight weighs approximately 43 kg (95 lb).

Additional details

If using with BW16765 hood guard, only 18 weights will fit. If using with BXX10036 hood guard, 20 weights will fit.

SU58373 front weight support for 20 suitcase weights

SU58373 front weight support for 20 suitcase weights

R262449 front weight support for 10 suitcase weights

R262449 front weight support for 10 suitcase weights

Overview

R262449 is a cast-iron front weight support that allows for up to 10 suitcase weights to be added to the front of the tractor for proper ballasting. The weight bracket weighs approximately 55 kg (121 lb), and Quik-Tatch™ weights can be easily added for additional ballast. Each front suitcase weight weighs approximately 43 kg (95 lb).

See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Additional details

NOTE: The front weight bracket is compatible with the hood and brush guards also installed.

R262449 front weight support for 10 suitcase weights

R262449 front weight support for 10 suitcase weights

Front suitcase weight

Front suitcase weight

One suitcase weight of 43 kg (95 lb).

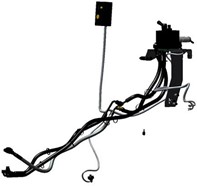

Fuel Tank

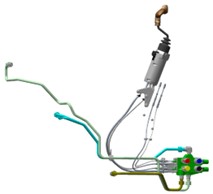

Hydraulics

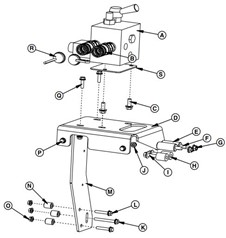

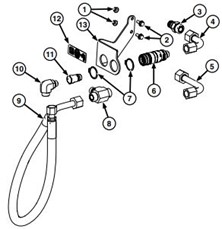

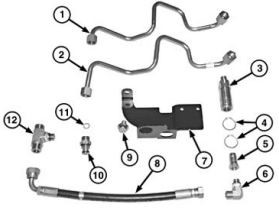

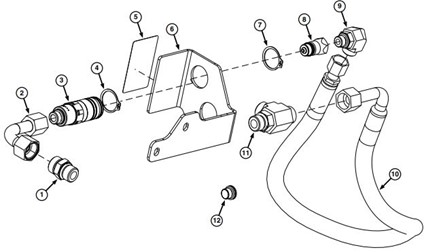

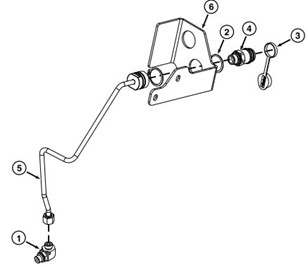

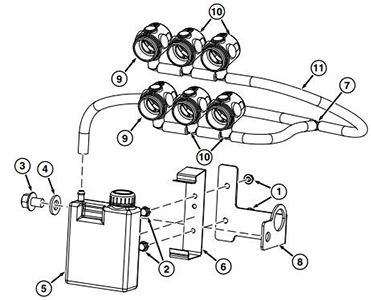

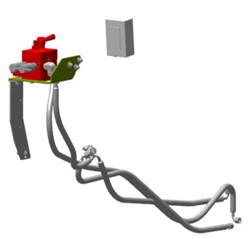

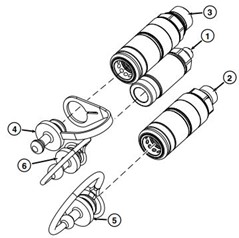

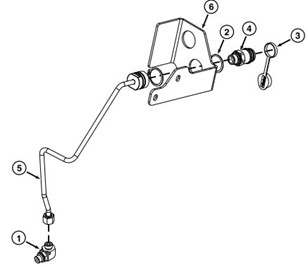

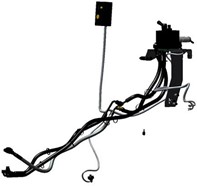

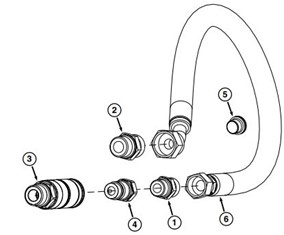

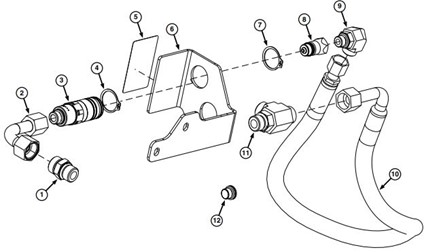

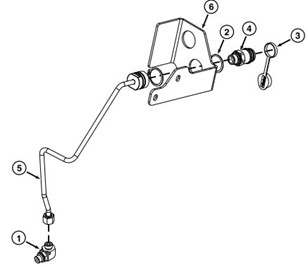

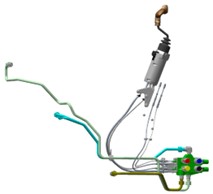

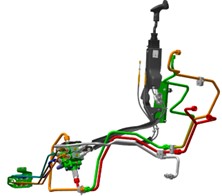

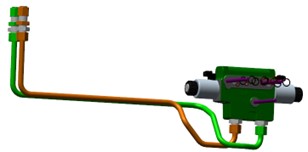

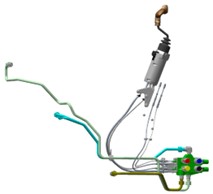

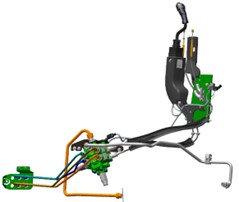

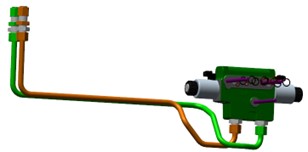

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

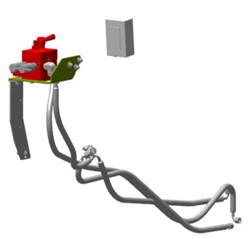

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

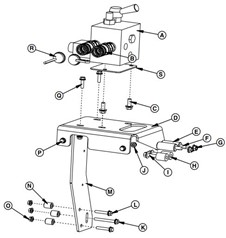

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

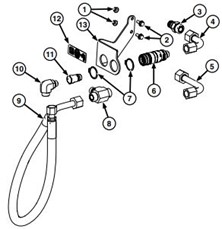

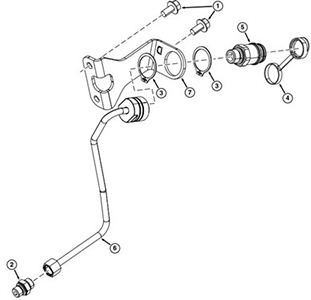

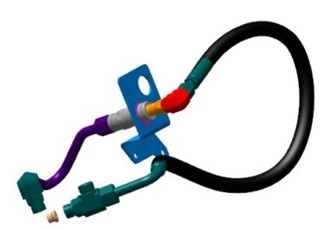

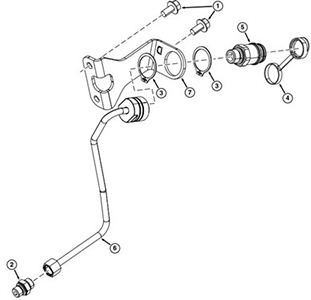

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

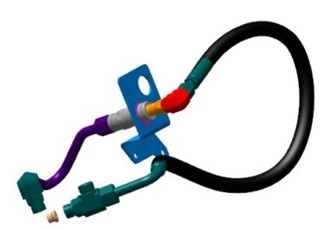

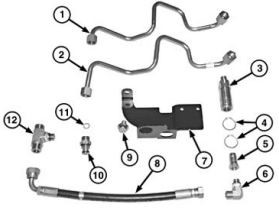

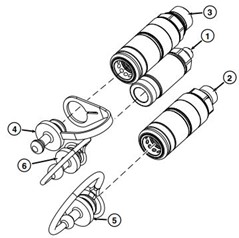

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

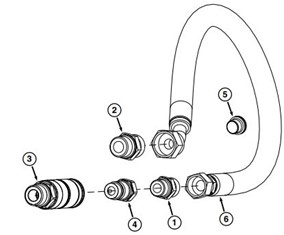

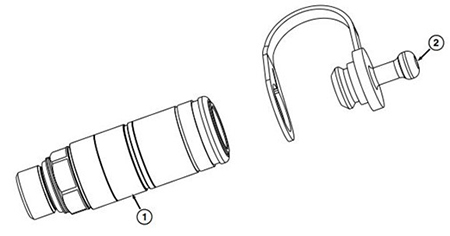

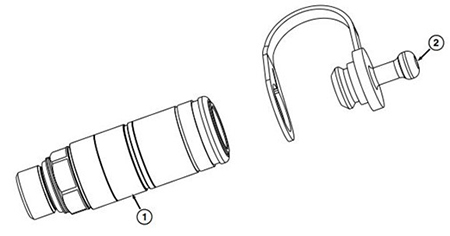

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

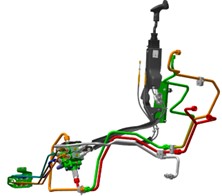

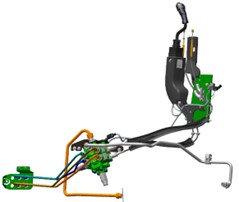

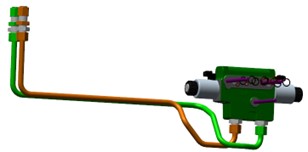

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

BSJ10345 motor control kit shown

BSJ10345 motor control kit shown

RE282528 Motor Control Kit shown

RE282528 Motor Control Kit shown

BXX10688 Motor Control Kit shown

BXX10688 Motor Control Kit shown

RE193598 Power Beyond Kit shown

RE193598 Power Beyond Kit shown

RE182800 Motor Control Kit shown

RE182800 Motor Control Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10282 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10194 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10241 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BSJ10240 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

BLV10416 Power Beyond Kit shown

R228089 Power Beyond Kit shown

R228089 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

RE242111 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10091 Power Beyond Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10092 Hydraulic Motor Case Drain and Motor Return Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10243 Motor Return Coupler Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10428 Motor Case Drain Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

BSJ10465 Rear SCV Oil Collection Kit shown

Overview

Adjust the continuous flow rate of the hydraulic fluid to the rear of the tractor with the motor control kit or get continuous flow with power beyond kits.

Benefits

- Allows for hydraulic flow rate adjustments

- Routes hydraulic flow to the rear of the tractor

- Enables the operator to run implements and attachments requiring continuous flow such as a hydraulic motor

- NOTE - A Power Beyond kit is NOT needed on any 5E 3-Cylinder tractors, as the hydraulic system design does not necessitate a power beyond kit.

Lighting

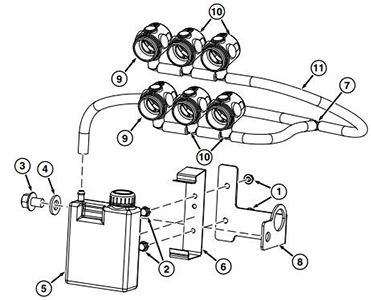

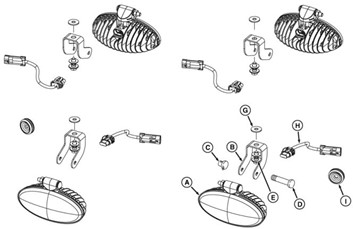

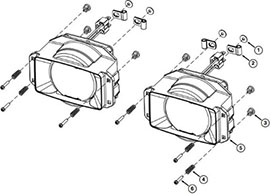

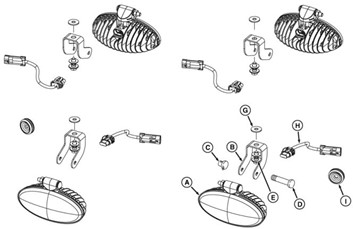

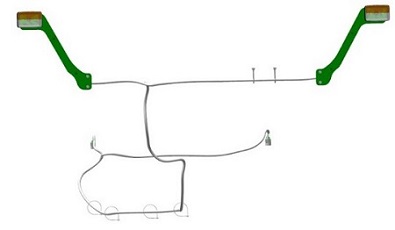

BSJ10416 loader light kit shown

BSJ10416 loader light kit shown

BSJ10422 loader light kit shown

BSJ10422 loader light kit shown

SJ12628 loader light kit shown

SJ12628 loader light kit shown

Overview

Loader light kits provide additional lights to be mounted on or near the loader mast arms allowing for additional light output when doing loader work.

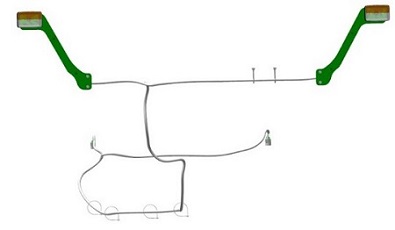

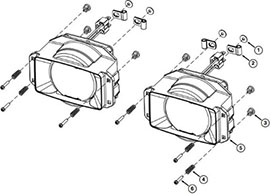

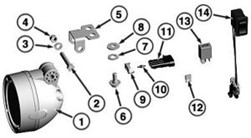

BSJ10325 LED Headlights shown

BSJ10325 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BSJ10056 Cab Auxiliary Work Light shown

BSJ10056 Cab Auxiliary Work Light shown

BSJ10163 Led Light Kit Shown

BSJ10163 Led Light Kit Shown

BSJ10478 LED Rear Work Light kit shown

BSJ10478 LED Rear Work Light kit shown

LVB25547 Rear Work Light shown on 5E tractor

LVB25547 Rear Work Light shown on 5E tractor

BSJ10420 Work Light Kit shown

BSJ10420 Work Light Kit shown

RE228854 Work Light Kit shown in forward facing mounting position

RE228854 Work Light Kit shown in forward facing mounting position

Overview

Work light kits offer additional light for increased visibility while working in dark conditions.

Benefits

- Adjustable lights for placing light where you need it

- OEM quality lights

- Increased light output

BSJ10325 LED Headlights shown

BSJ10325 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BXX10605 LED Headlights shown on MY23 5E Premium Cab tractor

BSJ10056 Cab Auxiliary Work Light shown

BSJ10056 Cab Auxiliary Work Light shown

BSJ10163 Led Light Kit Shown

BSJ10163 Led Light Kit Shown

BSJ10478 LED Rear Work Light kit shown

BSJ10478 LED Rear Work Light kit shown

LVB25547 Rear Work Light shown on 5E tractor

LVB25547 Rear Work Light shown on 5E tractor

BSJ10420 Work Light Kit shown

BSJ10420 Work Light Kit shown

RE228854 Work Light Kit shown in forward facing mounting position

RE228854 Work Light Kit shown in forward facing mounting position

Overview

Work light kits offer additional light for increased visibility while working in dark conditions.

Benefits

- Adjustable lights for placing light where you need it

- OEM quality lights

- Increased light output

BSJ10416 loader light kit shown

BSJ10416 loader light kit shown

BSJ10422 loader light kit shown

BSJ10422 loader light kit shown

SJ12628 loader light kit shown

SJ12628 loader light kit shown

Overview

Loader light kits provide additional lights to be mounted on or near the loader mast arms allowing for additional light output when doing loader work.

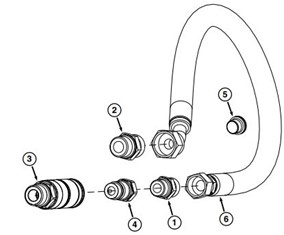

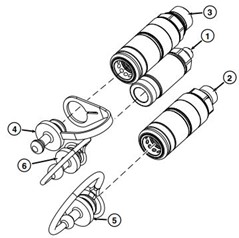

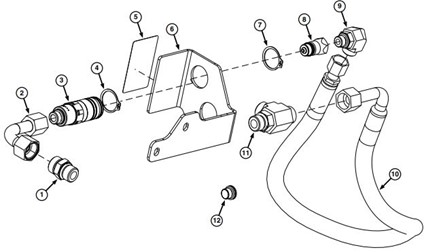

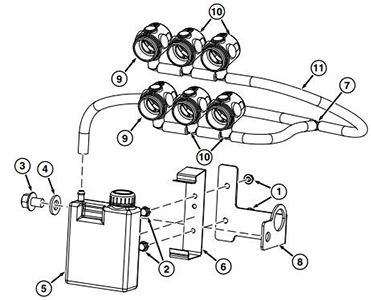

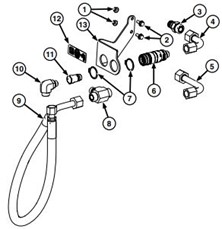

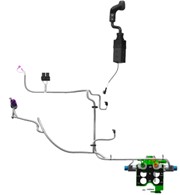

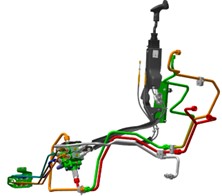

Mid Selective Control Valves

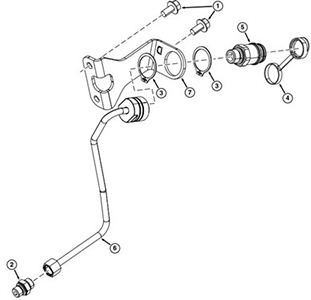

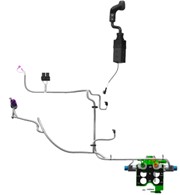

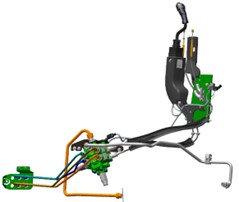

SJ13783 Mid-Coupler Kit shown

SJ13783 Mid-Coupler Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

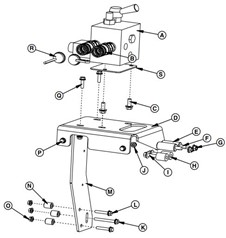

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

Overview

Provide hydraulic control to any front mounted implements with the John Deere Mid-Mounted SCV kits.

SJ13783 Mid-Coupler Kit shown

SJ13783 Mid-Coupler Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

Overview

Provide hydraulic control to any front mounted implements with the John Deere Mid-Mounted SCV kits.

SJ13783 Mid-Coupler Kit shown

SJ13783 Mid-Coupler Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

SJ17815 Dual Mid-Mount SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10101 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10227 Dual Mid to Triple SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10228 Dual Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10330 Mechanical Mid SCV Kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10333 Mechanical Mid SCV kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

BSJ10472 2 to 3 Mid SCV Kit shown

Overview

Provide hydraulic control to any front mounted implements with the John Deere Mid-Mounted SCV kits.

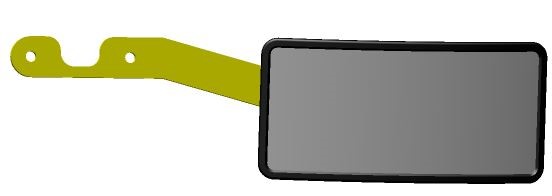

Mirrors

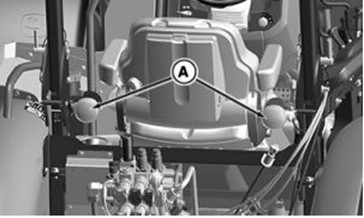

BlV10423 mirror kit shown on right-hand A pillar

BlV10423 mirror kit shown on right-hand A pillar

BSJ10347 mirror kit shown

BSJ10347 mirror kit shown

SJ10016 mirror kit shown

SJ10016 mirror kit shown

Similar kit (AL151224) shown for reference

Similar kit (AL151224) shown for reference

BSJ10473 mirror kit shown on 5M Tractor

BSJ10473 mirror kit shown on 5M Tractor

Overview

Increase rearward visibility from the operator’s station with a set of mirrors.

Benefits

- Provides rear view of the field or road

- Enables a better view of the rear hitch

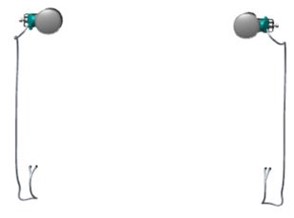

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open Station

Telescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open Station

Telescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open Station

Telescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Open Operator's Station

Canopy

Canopy

The canopy attaches to the rollover protective structure (ROPS) to protect the operator from inclement weather.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

A backrest extension improves operator comfort in cab and isolated open operator station tractors.

Operator's Station

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

RAM is a trademark of National Products Inc.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount

RAM is a trademark of National Products Inc.

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

AL212683 tie-rod assembly with mounting plates

AL212683 tie-rod assembly with mounting plates

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80459 117.6-mm (4.63-in.) tie-rod assembly

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

PF80460 38.1-mm (1.5-in.) ball mount on U-bolt

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

RE574454 76.2-mm (3-in.) tie-rod assembly with 38.1-mm (1.5-in.) ball on round mounting plate

UC17356 38.1-mm (1.5-in.) ball mount on universal square

UC17356 38.1-mm (1.5-in.) ball mount on universal square

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

RE558821 25.4-mm (1-in.) ball mount on 10-mm (0.4-in.) stud

AXE59372 clamp-style accessory mounting bracket

AXE59372 clamp-style accessory mounting bracket

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

BRE10482 25.4-mm (1-in.) T-slot ball mount assembly (left) and BRE10483 38.1-mm (1.5-in.) T-slot ball mount assembly

There are a variety of additional mounting part solutions available through John Deere to resolve unique mounting configuration needs. The table below includes several additional parts (not shown above) to aid in many different mounting needs.

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

- Self-leveling action reduces spills

- Durable design for rough environments

- Easy adjustable mounting for ideal placement

- Includes John Deere branded beverage insulator

- Compatible with most monitor brackets and all 10-mm threaded bosses

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10255 tablet mount assembly (1), BRE10015 cell phone mount assembly (2), and RE343680 L-shaped mounting bracket (3)

BRE10152 self-leveling cup holder assembly

BRE10152 self-leveling cup holder assembly

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

BRE10255 tablet mount assembly

BRE10255 tablet mount assembly

BXE10864 tablet mount assembly

BXE10864 tablet mount assembly

Mounting a tablet, cell phone, or beverage can be easily done with these solutions. These strong and simple-to-use solutions keep all important items right where they are wanted.

Power Take-Off (PTO)

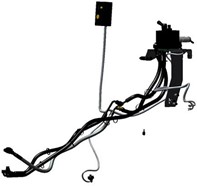

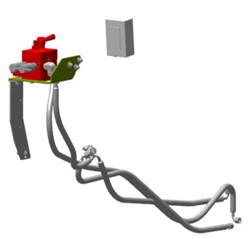

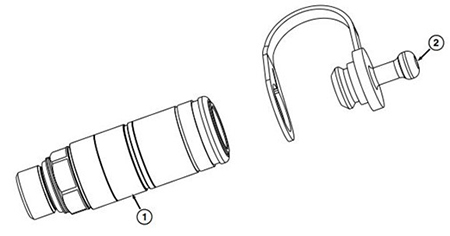

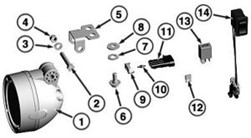

5M reversible PTO stub shaft shown

5M reversible PTO stub shaft shown

Overview

From mowing to baling to feed mixing and snow throwing, operators can operate an implement requiring 1000 rear PTO rpm or easily switch to 540 rpm to get the job done. Switching between 540 and 1000 rpm requires only removing a snap ring, flipping around the reversible shaft, replacing the snap ring, and shifting to the correct PTO speed. The dry cavity design makes this a less-mess, no-stress process without any oil spillage. The 5E 4-cylinder PTO rpm kits convert the factory two speed (540/540E rpm) to a two speed (540/1000 rpm), while the 5M kits upgrade the two speed (540/540E rpm) to a three speed (540/540E/1000 rpm), enabling more versatility.

Benefits

- Easily switch between implements requiring 540 and 1000 rpm PTO by simply reversing the interchangeable PTO shaft – no additional shafts or parts are needed.

- Less-mess, no-stress changeover process with a dry cavity design enhances productivity and increases uptime.

- 5M Tractors retain the ability to utilize a 540 Economy (540E) PTO, translating to fuel savings.

- NOTE: See the PTO detailed feature section for more information on E-PTO.

Additional details

|

|

A = snap ring B = snap ring groove C = bore |

| Reversible stub shaft (6 and 21 splines) | ||

To switch between 540 and 1000 speeds, simply remove the snap ring, flip the PTO shaft, and reinstall the snap ring. The tractor PTO operates at 540-rpm speed when the six-spline end of the shaft is visible, and at 1000-rpm speed when the 21-spline end of the shaft is visible.

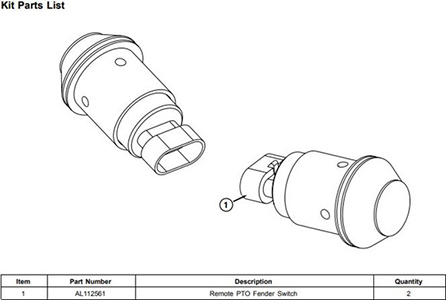

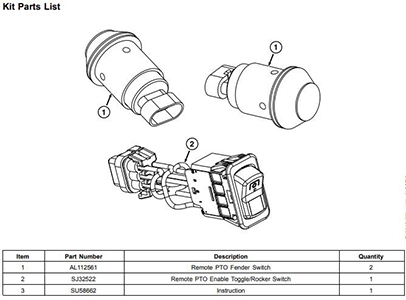

BSJ10327 Rear PTO fender switch kit shown

BSJ10327 Rear PTO fender switch kit shown

BSJ10563 Rear PTO fender switch kit shown

BSJ10563 Rear PTO fender switch kit shown

Overview

The rear PTO fender switch kits allow for operation of the rear PTO while depressing the PTO switch mounted on either side of the rear fenders.

Wheel Tread Width

Axle extensions are required to achieve tread settings greater than 78.7 in. on eight-position wheels.

Axle extensions are required to achieve wider tread settings.

Axle extensions are required to achieve wider axle tread settings.

Axle extensions are required to achieve wider axle tread settings.

Reviews

Location: Burlington, NC

Length of Ownership: 6months

Usage: Weekly

Bought my 2020 5075M w/cab new. I absolutely love it. I haven't experienced any other negatives other posters indicated. It has great power. Starts easily in all temps and hydraulics are awesome. There is not one thing I do not like. I use an E12 rotary cutter and it pulls it with ease. I use ePTO mode and it goes through high grass with the cutter low to the ground and I barely hear the engine change sounds. Highly recommend!

Location:

Length of Ownership: 1yearOrLonger

Usage: Weekly

HAVE HAD A 5075M A YEAR, HAS A CAB AND LOADER. PROBLEM WITH AC, REPLACED THE RESISTOR MYSELF WITH A GOOD QUALITY ONE (ITS IN THE ROOF OF CAB) RUNNING 10 FT PULL BEHIND JD BRUSH MOWER. RUNS LIKE IT SHOULD, BENT BOTH SIDES OF BUSHHOG POST HOLE DIGGER, EXTREMELY STRONG HYDRAULICS. SIZE IS PERFECT FOR MOWING, NICE FOR FE LOADER WITH AUTO REVERSER, JERKS GOING FWD BUT WILL ADJUST THE LINKAGE. CANT UNDERSTAND WHY JD DIDN'T SEAL AROUND CAB FLOOR AS DIRT GOES DOWN IN THE CRACKS.

Location: Indiana

Length of Ownership: 1yearOrLonger

Usage: Weekly

Bought this tractor because of the hydraulics and have not been disappointed. It has been very handy for anything we use it on.

Pros:

- useful

Location: Minnesota, USA

Length of Ownership: 1yearOrLonger

Usage: Daily

bought new last year and had problem from the start. First air conditioner didn't work, them after first oil change found out from oil sample that fuel was leaking into engine, had problem with engine stopping and then would not restart took numerous dealer time to fine problem and when it was time to use heater could not get any heat to cab because they had hoses kinked. Very poor quality control measures.

Location: High mountain valley, Colorado

Length of Ownership: 6months

Usage: Daily

I operate this tractor at elevations exceeding 7700 ft. and have found it to be extremely hard to start without the block heater even if temperatures are in the 25-40 degree F. range. Lifting a large round bale and using the reverser simultaneously will cause it to smoke excessively and nearly bog down completely. I am not only extremely disappointed with this tractor but also very frustrated with it. It has simply not lived up to my expectations. Compared to my 6420 with nearly 4000 hours . . . well, there really is no comparison in any way! I cannot recommend it and do not plan to keep it around the ranch.

Pros:

- turning radius

Cons:

- poor engine performance

Videos

© COPYRIGHT 2026 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By