1023E

Sub-Compact Tractor

- Powerful Final Tier 4-compliant diesel engine

- AutoConnect™ mid-mower deck can be installed or removed in less than 5 minutes

- †

Starting At:

$15,149.00

View Product Brochure

Features

Drive-over deck makes connection simple

Drive-over deck makes connection simple

1 Family Tractors are designed to minimize the time and effort needed to switch-out implements to accommodate different jobs.

- AutoConnect Deck System: Connect a mid-mount mower deck to the tractor in less than 60 seconds without leaving the seat except to lock the gauge wheels.

- Load-N-Go attachment: Easily move your 54D or 60D AutoConnect Deck with your John Deere Loader after it has been disconnected from the tractor with the Load-N-Go ramps.

- Quik-Park™ Loader System: 120R Quik-Park™ Loaders are designed for easy mounting and removal in about a minute, with no tools needed.

- Quik-Tatch™ front hitch: Save time switching front implements like a snow blower, rotary broom, or front blade without tools.

- iMatch™ quick-hitch: Easily hookup Category 1 implements in seconds using three fixed points to back in and pick up rear implements without leaving the seat

- Position control hitch: Set the rear hitch height and then consistently lower the hitch to the exact height every time, which is especially useful in grading and leveling applications.

- Quik-Knect™ system: Connect power take-off (PTO)-driven implements quickly and with low physical effort. The Quik-Knect system utilizes one connector for the tractor’s PTO shaft and a designated connector for each implement which eliminates twisting and forcing splines to align.

1 Family Tractors can have up to three implements mounted simultaneously due to standard dual selective control valves (SCVs), allowing you to switch from using one implement to another without stopping to adjust. When a third SCV kit is added, the number of possible combinations is greatly increased.

Twin Touch™ pedals

Twin Touch™ pedals

The hydrostatic transmission’s infinite ground speeds and direction of travel are both controlled with the Twin Touch foot pedals.

- Ideal for loader or mower applications where frequent direction and speed changes are needed

- No clutching for fast direction changes

- Match the job at hand with infinite ground speeds

Standard 4WD and power steering make 1 Family Tractors excellent for mowing

Standard 4WD and power steering make 1 Family Tractors excellent for mowing

Both 4WD and power steering are standard equipment on the 1 Family Tractors. This combination allows for excellent maneuverability and ease of operation.

- Narrow overall width allows you to work in tight areas where most compact tractors just cannot fit. The 144.8-cm (57-in.) wheel base and 119.4 cm (47 in.) overall width gives great stability for all types of terrain.

- Power steering means fewer turns of the steering wheel than manual steering, which is especially valuable when mowing around obstacles or during front loader work.

- High horsepower-to-weight ratio makes the 1 Family Tractors a good choice for a variety of tasks. The overall tractor weight reduces ground compaction and makes them excellent for mowing.

- The fully-independent power take-off (PTO) allows engaging and disengaging of the PTO without stopping tractor movement. This is important when driving across obstacles such as driveways while mowing.

Open operator's station (1025R shown)

Open operator's station (1025R shown)

The 1023E open operator station is designed for greater comfort and increased visibility.

Comfortable operation

- Thick, textured rubber floor mat reduces vibrations and absorbs shock and noise.

- Step-through flat platform and fender-mounted handrails make it easy to get on and off the tractor from either side.

- Controls are conveniently located next to the fenders and are color-coded for quick identification.

- Easy-lift hood with dual gas-charged lift struts as standard equipment. A simple flip of the latch lets you open the rugged composite hood, providing wide open access to the engine compartment.

- Foldable rollover protective structure (ROPS) keeps you protected during operation and improves the ability to store tractor in a garage.

Foldable Roll-Gard ROPS

Foldable Roll-Gard ROPS

Foldable Roll-Gard™ ROPS is standard equipment on 1023E.

Increased visibility

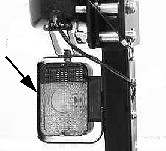

Standard (and optional) lighting shown

Standard (and optional) lighting shown

- Sloping hood design provides improved visibility especially during front loader work

- Standard lighting equipment allows you to work from early in the morning to late at night:

- Two front-mounted sealed-beam halogen headlights

- Two amber-flashing warning/hazard lights mounted on the side of the ROPS with reflectors

- Built-in tail light on one warning/hazardous light

- Additional front- and rear-light kits are available

Instrumentation

Instrumentation

Instrumentation

Updated instrumentation is standard equipment for operating convenience and confidence. Instrumentation includes:

- Tach/hour meter

- Oil-pressure indicator light

- Alternator-indicator light

- Flashing-warning lights

- Coolant-temperature light

Suspension seat

Suspension seat

Suspension seat

The spring suspension seat adjusts fore/aft for operator convenience. The seat adjustment lever is located in the center under the seat area. The seat flips forward for protection from the elements.

Mower deck height-adjustment knob

Mower deck height-adjustment knob

Mower deck height-adjustment knob

- The mower deck height-adjustment knob allows the mower height to be adjusted from 2.5 cm to 10.2 cm (1 in. to 4 in.).

- A spring-loaded detent ensures the height position is locked into place.

- The transport lock position holds the deck 10.2-cm (4-in.) from the ground, so that rear implements can be used separately while the mower is installed.

Beverage holder and additional storage

Beverage holder and additional storage

Beverage holder and additional storage

The beverage holder is contour-molded and seated into the fender for a clean look. It is conveniently located and dual-sized to accommodate many containers. The placement of the cup holder is within arm's reach.

Additional storage is conveniently placed into the fender for loose items like keys and work gloves.

Fuel fill and fuel gauge locations

Fuel fill and fuel gauge locations

Fuel fill and fuel gauge locations

The fuel fill location is conveniently accessible on the left-hand side fender. The fuel gauge is located in close proximity to make the fuel refilling process easier.

Mid-mower lift system options

Mid-mower lift system options

Mid-mower lift system options

Standard mechanical mower lift

The standard mechanical mower lift system moves the mower in conjunction with the rear implements and comes factory-installed on 1 Family Tractors.

Optional hydraulic mower lift

The optional hydraulic mower lift system allows the mower to be raised and lowered independently of the rear implements. It uses the loader joystick to lift and lower the mower deck.

Optional independent hydraulic mower lift

The optional independent hydraulic lift system allows the mower to be raised and lowered independently of the rear and front implements. It operates using a rocker switch mounted on the tractor, located at the operator’s left knee.

For more information on this mid mower lift system click here.

Specs & Compare

Key Specs | 1023E Current Model |

| Engine power (gross) | SAE J1995 rated power: 16 kW 21.5 hp 21.8 PS at 3200 rpm |

| Power take-off (PTO) power | 11.1 kW 14.9 hp |

| Steering hydraulics | 13.2 L/min 3.5 gpm |

| Implement hydraulics | 13.2 L/min 3.5 gpm |

| Hitch type | Limited Category 1 |

| Lift capacity, 24-in. behind link arms | 344 kg 758 lb |

| Standard transmission; forward/reverse | Hydrostatic - two range |

| Cruise control | No |

| Approximate shipping weight (open-station; cab) | Open station: 656 kg 1446 lb Cab: Not applicable |

| Wheelbase | 1450 mm 57.1 in. |

Engine | |

| Family | |

| Manufacturer | Yanmar® |

| Engine model | 3TNM74F-NCJT |

| Engine power (gross) | SAE J1995 rated power: 16 kW 21.5 hp 21.8 PS at 3200 rpm |

| Power take-off (PTO) power | 11.1 kW 14.9 hp |

| Rated engine speed | 3200 rpm |

| Type | Diesel |

| Injection pump type | Indirect injection |

| Aspiration | Natural |

| Emissions compliance | Final Tier 4 |

| Cylinders/displacement | Three cylinders: 0.993 L 60.6 cu in. |

| Number of cylinders | Three |

| Cylinder liners | Cast-in-block |

| Bore and stroke | 74 x 77 mm 2.91 x 3.03 in. |

| Compression ratio | 23.5:1 |

| Lubrication | Pressurized |

| Cooling system | Water pump |

| Air cleaner | Dual element |

| Engine torque at rated speed | 47.7 Nm 35.2 lb-ft |

| Fuel tank capacity | 24 L 6.3 U.S. gal. |

Electrical | |

| Battery size | 500 CCA |

| Alternator (12-V) | 40 amp |

| Starter size | 1.2 kW 1.6 hp |

Fuel system | |

| Type | Indirect injection |

| Fuel consumption | |

Transmission | |

| Standard transmission; forward/reverse | Hydrostatic - two range |

| Optional transmission; forward/reverse | |

| Left-hand reverser | No |

| Transmission gear ranges | |

| Final drive | Spur gear |

| Brakes | Wet disc (left-hand pedal) |

| Steering | Power |

| Clutch, wet/dry | |

| Clutch disk diameter wet clutch | |

| Axle capacity | Front 612 kg 1349 lb Rear 715 kg 1576 lb |

| Creeper | No |

| Cruise control | No |

| Differential lock | Yes |

| Drawbar maximum vertical load | |

Hydraulics | |

| Type | Open center |

| Pump rated output | Steering 13.2 L/min 3.5 gpm Implement 13.2 L/min 3.5 gpm 24 L/min 6.3 gpm |

| Pump type | Single gear |

| Maximum operating pressure | 138 bar 2000 psi |

| Draft control sensing | Select control |

| Remote control valves available | Three |

3-point hitch | |

| Type | Limited Category 1 |

| Lift capacity, 24-in. behind link arms | 344 kg 758 lb |

Power take-off (PTO) | |

| Standard | Rear: 540 rpm Mid: 2100 rpm |

| Optional | |

| Control | Independent |

| Clutch | Wet disk |

| Brake (for mid and rear PTO) | Wet disk |

| Engagement method | |

Fluid capacities | |

| Crankcase with filter | 2.7 L 2.9 qt |

| Transmission and hydraulic system | 12.3 L 3.2 gal. |

Final drive | |

| Type | Spur gear |

| Differential lock | Yes |

Operator station | |

| Rollover protective structure | Type Foldable Yes |

| Platform - flat/straddle | One-piece semi flat |

| Gear shift location - console/floor | Left-hand side |

Cab | |

| Compliance | |

| Visibility | |

| Air conditioning, temperature differential | |

| Doors | |

| Noise rating | |

| Seat equipment | |

Dimensions | |

| Height | |

| Wheelbase | 1450 mm 57.1 in. |

| Front axle clearance | 195 mm 7.7 in. |

| Turning radius with brakes | |

| Turning radius without brakes | Outside front tire: 2.51 m 8.2 ft |

| Limited slip differential | No |

| Approximate shipping weight (open-station; cab) | Open station: 656 kg 1446 lb Cab: Not applicable |

Tires | |

| Front | R3 Turf: 18x8.50-10 R4: 18x8.5-10 |

| Rear | R3 Turf: 26x12-12 R4: 26x12-12 |

| Front tread range | 931 mm 36.7 in. |

| Rear tread spacing | 895 mm 35.2 in. |

Miscellaneous | |

| Toolbox | Yes |

| Tilt steering wheel | |

| 12-V Outlet | |

Additional information | |

Offers & Discounts

Accessories & Attachments

Accessories

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Tool storage products on wall

Tool storage products on wall

Tool storage products on 3E Tractor

Tool storage products on 3E Tractor

5WS812430 rollover protective structure (ROPS) rack

5WS812430 rollover protective structure (ROPS) rack

5WS812430 ROPS rack on 3E

5WS812430 ROPS rack on 3E

5WS812435 universal mount

5WS812435 universal mount

5WS812460 chainsaw holder

5WS812460 chainsaw holder

5WS812450 two tool holder

5WS812450 two tool holder

5WS812455 four tool holder

5WS812455 four tool holder

5WS812466 leaf blower holder

5WS812466 leaf blower holder

5WS812470 chain box

5WS812470 chain box

5WS812475 on ROPS rack

5WS812475 on ROPS rack

5WS812475

5WS812475

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

5WS812480, 5WS812485, and 5WS812490 on ROPS rack

Overview

The John Deere tool storage solutions provide the tractor customer with customizable tool storage to carry commonly used landscaping tools and power equipment on the tractor without having to make multiple trips to the garage.

Benefits

Backhoes

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

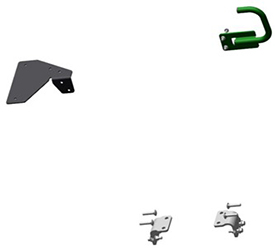

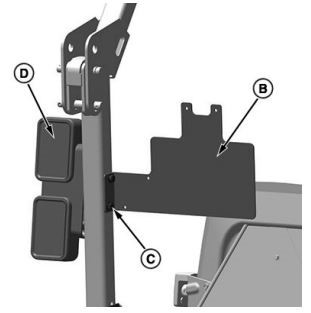

BXX10279 Subframe mounting kit shown

BXX10279 Subframe mounting kit shown

BLV10594 Subframe mounting kit shown

BLV10594 Subframe mounting kit shown

BXX10278 Grab Handle and mounting parts shown

BXX10278 Grab Handle and mounting parts shown

Overview

Backhoe mounting kits are required to add a backhoe to a compact utility tractor.

NOTE: Power beyond kit is required on all tractors for proper backhoe installation and functionality

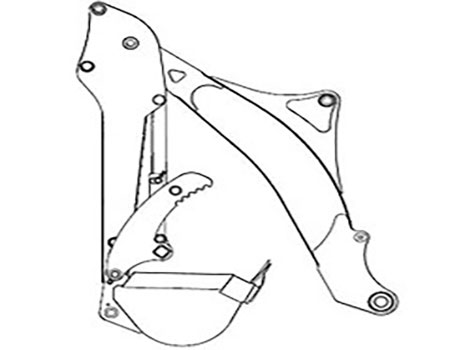

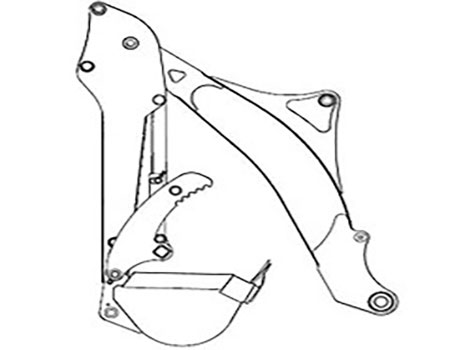

Mechanical thumb shown on 485 backhoe

Mechanical thumb shown on 485 backhoe

Thumb schematic shown

Thumb schematic shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10891 Hydraulic Thumb Kit shown

BXX10891 Hydraulic Thumb Kit shown

Overview

Backhoe thumb kits add increased functionality of the backhoe by allowing an operator to easily grab items such as logs and debris. Thumb kits come in both mechanical and hydraulic versions with fixed or on the fly position adjustments.

Mechanical thumb shown on 485 backhoe

Mechanical thumb shown on 485 backhoe

Thumb schematic shown

Thumb schematic shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10248 Hydraulic thumb kit shown

BXX10891 Hydraulic Thumb Kit shown

BXX10891 Hydraulic Thumb Kit shown

Overview

Backhoe thumb kits add increased functionality of the backhoe by allowing an operator to easily grab items such as logs and debris. Thumb kits come in both mechanical and hydraulic versions with fixed or on the fly position adjustments.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

BXX10246 Trenching bucket shown

BXX10246 Trenching bucket shown

BXX10247 Ripper tooth shown

BXX10247 Ripper tooth shown

406-mm (16-in.) bucket for 260 backhoe shown

406-mm (16-in.) bucket for 260 backhoe shown

Heavy-duty roll tube for extra strength

Heavy-duty roll tube for extra strength

Overview

Backhoe buckets offer increased backhoe performance depending on the task at hand. Whether you need a heavy-duty bucket with more capacity, a trencher bucket for a sprinkler install or ripper tooth for hard packed soils, the high strength construction will keep you digging long into the future.

Hydraulics

Frontier™ grapple shown on 120R and 2025R

Frontier™ grapple shown on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

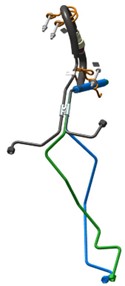

120R loader connection location on 1E and 1R tractor

120R loader connection location on 1E and 1R tractor

120R loader connection on 2025R tractor

120R loader connection on 2025R tractor

Joystick for usage with third-function

Joystick for usage with third-function

120R loader third-function lines on boom

120R loader third-function lines on boom

120R loader third-function connection for implements at torque tube area

120R loader third-function connection for implements at torque tube area

Overview

Add versatility to the tractor and loader package with the addition of a third-function kit. They enable the use of attachments such as four-in-one buckets, root grapples, and hydraulic angling blades further enhancing the tractors’ ability to help get jobs done.

Tractor series |

Loader model |

Loader bundle for non-self-leveling loaders |

Loader bundle for mechanical self- leveling loaders |

Tractor bundle |

MY20 and newer 1E and 1R |

120R |

BXX10268 |

BXX10370 |

BXX10835 |

MY20 and newer 2025R |

120R |

BXX10210 |

BXX10375 |

BXX10846 |

Frontier™ grapple shown on 120R and 2025R

Frontier™ grapple shown on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

120R loader connection location on 1E and 1R tractor

120R loader connection location on 1E and 1R tractor

120R loader connection on 2025R tractor

120R loader connection on 2025R tractor

Joystick for usage with third-function

Joystick for usage with third-function

120R loader third-function lines on boom

120R loader third-function lines on boom

120R loader third-function connection for implements at torque tube area

120R loader third-function connection for implements at torque tube area

Overview

Add versatility to the tractor and loader package with the addition of a third-function kit. They enable the use of attachments such as four-in-one buckets, root grapples, and hydraulic angling blades further enhancing the tractors’ ability to help get jobs done.

Tractor series |

Loader model |

Loader bundle for non-self-leveling loaders |

Loader bundle for mechanical self- leveling loaders |

Tractor bundle |

MY20 and newer 1E and 1R |

120R |

BXX10268 |

BXX10370 |

BXX10835 |

MY20 and newer 2025R |

120R |

BXX10210 |

BXX10375 |

BXX10846 |

Frontier™ grapple shown on 120R and 2025R

Frontier™ grapple shown on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

Frontier four-in-one bucket on 120R and 2025R

120R loader connection location on 1E and 1R tractor

120R loader connection location on 1E and 1R tractor

120R loader connection on 2025R tractor

120R loader connection on 2025R tractor

Joystick for usage with third-function

Joystick for usage with third-function

120R loader third-function lines on boom

120R loader third-function lines on boom

120R loader third-function connection for implements at torque tube area

120R loader third-function connection for implements at torque tube area

Overview

Add versatility to the tractor and loader package with the addition of a third-function kit. They enable the use of attachments such as four-in-one buckets, root grapples, and hydraulic angling blades further enhancing the tractors’ ability to help get jobs done.

Tractor series |

Loader model |

Loader bundle for non-self-leveling loaders |

Loader bundle for mechanical self- leveling loaders |

Tractor bundle |

MY20 and newer 1E and 1R |

120R |

BXX10268 |

BXX10370 |

BXX10835 |

MY20 and newer 2025R |

120R |

BXX10210 |

BXX10375 |

BXX10846 |

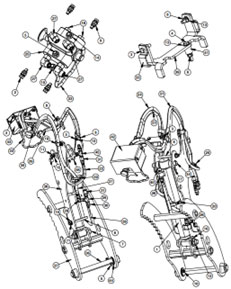

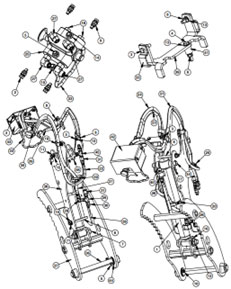

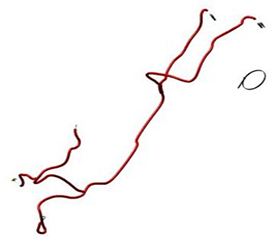

Power beyond kit example shown

Power beyond kit example shown

LVB25956 Power beyond kit shown

LVB25956 Power beyond kit shown

BLV11216 Power beyond kit shown

BLV11216 Power beyond kit shown

BXX10915 Power beyond kit shown

BXX10915 Power beyond kit shown

BXX10837 Power Beyond Kit shown

BXX10837 Power Beyond Kit shown

BLV10381 Power Beyond Kit shown

BLV10381 Power Beyond Kit shown

Overview

Power beyond kits provide access of pressurized hydraulic oil at the rear of the tractor for operating attachments equipped with an open center control valve, such as a backhoe and log splitter when continuous hydraulic flow is required.

NOTE: When nothing is hooked up to the power beyond, it is critical the loop is closed to ensure proper hydraulic flow.

NOTE: Power beyond kits are not included in the backhoe frame attachments and must be ordered separately.

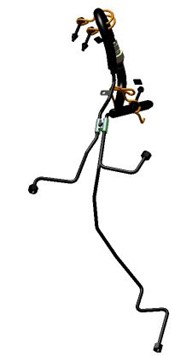

BLV10948 hydraulic hose kit shown

BLV10948 hydraulic hose kit shown

Overview

The hydraulic hose kit includes hoses and fittings to route hydraulic connections to the rear of the tractor for use with rear implements.

Lighting

The forward-lighting kit provides extra visibility when working in dark conditions. Lights attach to the brush guards located on the rollover protective structure (ROPS). Each kit contains two lights.

NOTE: Requires BLV10400 warning light brush guard kit and LVB26026 light kit harness. Not compatible with LVB25547 rear work light kit (1023E).

NOTE: Requires BLV10400 warning light brush guard kit. Not compatible with LVB25547 rear work light kit (1025R, 2025R, 2032R, 2038R, 3025E, 3032E, 3038E, 4105, 4044M, 4052M, 4066M).

NOTE: Requires BLV10620 premium warning light brush guard kit. Not compatible with LVB25547 rear work light kit (3033R, 3039R, 3046R, 4044R, 4052R, 4066R).

Rollover protective structure (ROPS) mounted LED work lights

An optional LED work light kit is available for all open-station compact utility tractors. These lights provide extra visibility when working in dark conditions and have 180-degree rotation to face forward or backward. The kit contains two lights and the mounting hardware required for installation.

This lighting kit is mounted to the warning light brush guard kit, which is mounted to the ROPS and requires attachment BLV10400 for installation.

The halogen work light kit attachment is still available (LVB25546).

Shown on 4000 TEN Series Tractor

Shown on 4000 TEN Series Tractor

ROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

For open-station tractors only.

Two guards included in each kit.

LVB25546 Forward-lighting kit shown

LVB25546 Forward-lighting kit shown

LVB25547 Rear worklight kit shown

LVB25547 Rear worklight kit shown

LVB26026 Rear worklight harness kit shown

LVB26026 Rear worklight harness kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10620 Rollover protective structure (ROPS) brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10399 Worklight brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10400 Warning light brush guard kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium light-emitting diode (LED) worklight kit shown

BLV10673 Premium LED worklight kit shown

BLV10673 Premium LED worklight kit shown

Overview

Worklight kits offer additional light for increased visibility while working in dark conditions.

Brush guard kits protect lights from damage caused by low branches on tress and provide a mount solution for additional worklights.

Benefits

- Adjustable lights for placing light where operators need it

- Additional protection from branches

- Original equipment manufacturer (OEM) quality lights

ROPS warning-light brush guards protect turn signal/warning lights from damage caused by low branches on trees.

Two guards are included in each kit and are for open-operator station (OOS) tractors only.

Light wire harness required to use with LVB25547 rear-work light kit and LVB25546 forward-lighting kit on 1023E Tractors.

Rear work light

Rear work light

This kit provides light to the rear of the tractor for evening work.

For open-station tractors only, this kit contains individual light.

Allow 30 minutes to install.

NOTE: Kit includes one rear light.

NOTE: Both the rear- and forward-work lights are compatible together and with the light-brush guard kits. The light kit contains a two-to-four pigtail that plugs into the main harness, as if only plugging one set of lights, providing two sets of plugs to use for forward and rear-work lights. The forward light is installed on top of the brush guard, and the rear light is installed inside the ROPS using the bolt holding the light and brush guard on.

NOTE: For 102E3 and 1026R Tractors – kit interference during backhoe operations (mounted inside ROPS) – use LVB25546 forward-light kit as an alternative.

Open Operator's Station

LP64809 canopy shown

LP64809 canopy shown

Overview

Steel frame construction, ABS plastic roof. Approved for use on small chassis compact utility tractors with both fixed and folding roll over protective structures (ROPS). The canopy protects the operator from direct sun exposure and weather. Heavy-duty construction that is built to last.

BXX10277 License plate kit shown

BXX10277 License plate kit shown

Overview

License plate kits allow an operator to display a license plate on the tractor in order to meet local laws and regulations in which to drive on public roads.

LP95637 Tractor cover shown

LP95637 Tractor cover shown

Overview

Provide all-weather protection to the tractor when not in use with a tractor cover.

Benefits

- Weather resistant material

- Protects against UV damage, rain, dirt, etc.

- Keeps the seat dry

Operator's Station

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

Overview

Mounting a tablet or cell phone can be done easily with these solutions. These strong and simple-to-use mounts keep all important items right where they are wanted. They are the perfect solution for operators who move to multiple machines, reference information, or make calls or video share while doing repairs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Tablet, cellphone, and cupholder mounted on mounting bracket in 5E Cab

Locking suction assembly mounted in 5E Cab

Locking suction assembly mounted in 5E Cab

RE343680 mounted in 5E Cab

RE343680 mounted in 5E Cab

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

RE576490 (top) and RE558821 (bottom) mounted in 5E Cab shown

There are several locations to mount the threaded ball into the cab. Any of the threaded bosses included in the cab can be used (once the factory plastic plug is removed). The threaded ball can also be mounted into the slot of the RE343680 mounting bracket (also sold separately).

Build Your Own Mounting Solutions

Tie rods and ball mounts shown on RE343680

Tie rods and ball mounts shown on RE343680

AL212683 tie-rod assembly

AL212683 tie-rod assembly

PF80460 ball mount

PF80460 ball mount

RE574454 tie rod assembly

RE574454 tie rod assembly

UC17356 ball mount

UC17356 ball mount

AXE59372 clamp-style accessory bracket shown

AXE59372 clamp-style accessory bracket shown

BRE10482 and BRE10483 T-slot mounts shown

BRE10482 and BRE10483 T-slot mounts shown

BXE10864 tablet mount assembly shown

BXE10864 tablet mount assembly shown

BSJ10490 Display rail shown

BSJ10490 Display rail shown

Overview

Mount your John Deere displays, cell phone, tablet, cup holder, or aftermarket products with these mounting solutions from John Deere. There are also variety of additional mounting part solutions available to resolve your unique mounting configuration needs.

Benefits

- Operators can keep important items in the right place.

- Customizable to operators needs.

BXE10606 locking suction mount cell phone assembly

BXE10606 locking suction mount cell phone assembly

BXE10607 locking suction mount tablet assembly

BXE10607 locking suction mount tablet assembly

Overview

Mounting a tablet or cell phone can be done easily with these solutions. These strong and simple-to-use mounts keep all important items right where they are wanted. They are the perfect solution for operators who move to multiple machines, reference information, or make calls or video share while doing repairs.

Rear Power Take-Off (PTO)

Rear Wheel Weights

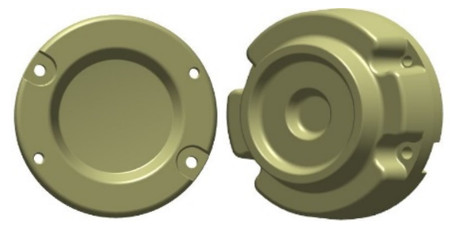

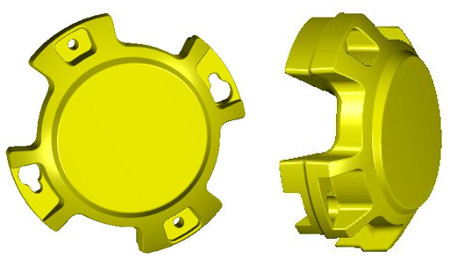

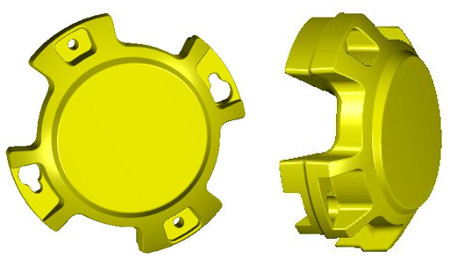

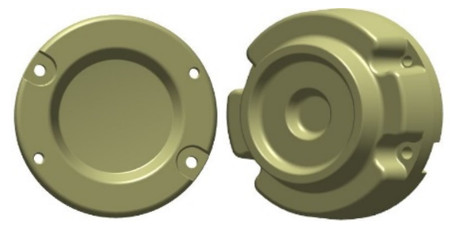

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

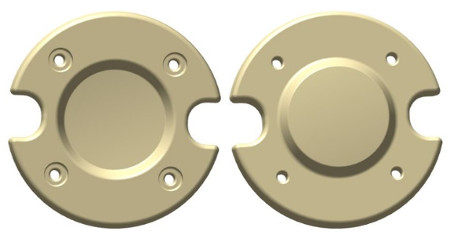

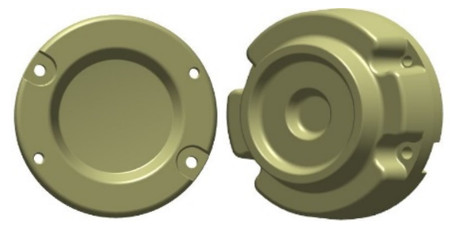

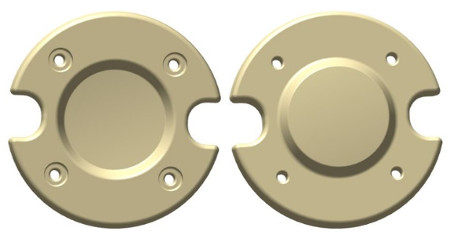

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

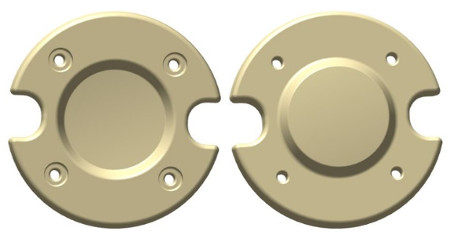

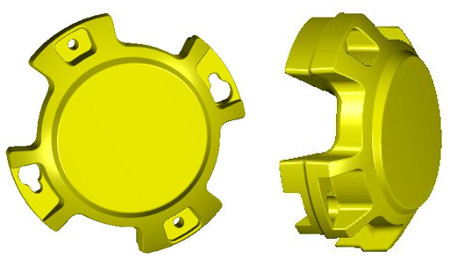

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

UC13499 32-kg (70-lb) cast-iron rear wheel weight (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17976 22.7-kg (50-lb) plastic-shell rear wheel weight with hardware, not stackable (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17972 22.7-kg (50-lb) cast-iron wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

BM17965 28.1-kg (62-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

T19293 48.1-kg (106-lb) rear wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

BM17968 22-kg (48.5-lb) wheel weight (inner and outer face shown)

Overview

Wheel weights provide extra traction and stability by adding ballast to the rear wheels.

Click here to view the Wheel Weight Compatibility Guide.

NOTE: Plastic rear-wheel weight comes with necessary hardware for installation.

23-kg (50-lb) cast-iron wheel weights

23-kg (50-lb) cast-iron wheel weights

For 23-kg (50-lb) cast-iron wheel weights on 26x12-in. rear tyres:

NOTE: Order two sets for both sides of the tractor.

33-kg (72-lb) starter cast-iron wheel weight

33-kg (72-lb) starter cast-iron wheel weight

For 33-kg (72-lb) starter cast-iron wheel weight on 26x12-in. rear tyres:

NOTE: Order two sets for both sides of the tractor.

33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s)

33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s)

For 33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s):

NOTE: Order two sets for both sides of the tractor

NOTE: Plastic rear-wheel weight comes with necessary hardware for installation.

23-kg (50-lb) cast-iron wheel weights

23-kg (50-lb) cast-iron wheel weights

For 23-kg (50-lb) cast-iron wheel weights on 26x12-in. rear tyres:

NOTE: Order two sets for both sides of the tractor.

33-kg (72-lb) starter cast-iron wheel weight

33-kg (72-lb) starter cast-iron wheel weight

For 33-kg (72-lb) starter cast-iron wheel weight on 26x12-in. rear tyres:

NOTE: Order two sets for both sides of the tractor.

33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s)

33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s)

For 33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s):

NOTE: Order two sets for both sides of the tractor

NOTE: Plastic rear-wheel weight comes with necessary hardware for installation.

23-kg (50-lb) cast-iron wheel weights

23-kg (50-lb) cast-iron wheel weights

For 23-kg (50-lb) cast-iron wheel weights on 26x12-in. rear tyres:

NOTE: Order two sets for both sides of the tractor.

33-kg (72-lb) starter cast-iron wheel weight

33-kg (72-lb) starter cast-iron wheel weight

For 33-kg (72-lb) starter cast-iron wheel weight on 26x12-in. rear tyres:

NOTE: Order two sets for both sides of the tractor.

33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s)

33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s)

For 33-kg (72-lb) starter and 23-kg (50-lb) cast-iron weight(s):

NOTE: Order two sets for both sides of the tractor

Rear Wheels and Tires

Tire chains on X300 Tire

Tire chains on X300 Tire

Overview

Tire chains provide added traction in snowy and icy conditions.

Additional details

- Roadmaster tire chains have a single cross-chain design that runs across the tire (resembles a ladder) and is used for on-road and off-road conditions

- Duo Grip tire chains have a dual cross chain design that forms an “H pattern” and is suited specifically for off-road conditions

Tire chains on X300 Tire

Tire chains on X300 Tire

Overview

Tire chains provide added traction in snowy and icy conditions.

Additional details

- Roadmaster tire chains have a single cross-chain design that runs across the tire (resembles a ladder) and is used for on-road and off-road conditions

- Duo Grip tire chains have a dual cross chain design that forms an “H pattern” and is suited specifically for off-road conditions

Tire chains

Tire chains

Tire chains increase traction dramatically under ice and snow conditions.

NOTE: Not intended for use on all four rear tires on the TH 6x4.

Three-Point Hitch

LP25001 3pt hitch receiver hitch shown

LP25001 3pt hitch receiver hitch shown

Overview

Move trailers and other wheeled implements easily with the 3-point receiver hitch.

Benefits

- Easily move trailers and other wheeled implements

- Accepts standard 2-inch receivers ball mounts

- Compatible with CAT 1 IMatch Quick Hitch or and CAT 1 3pt tractor hitch

Magnetic hitch pin

Magnetic hitch pin

Fits John Deere lawn and garden tow behind attachments.

- Strong magnetic grip

- Rust resistant

- Easy to install, secure fit

Ordering information

Customers, please contact your local John Deere dealer for availability and pricing information.

Magnetic hitch pin

Order number: LP63768

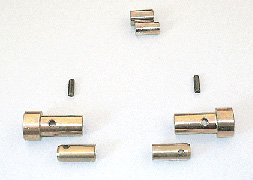

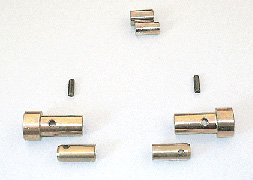

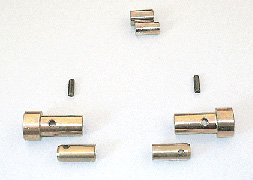

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

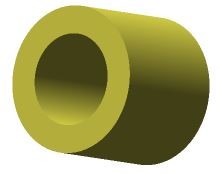

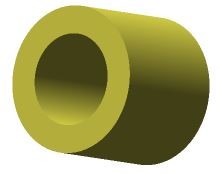

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

iMatch Quick-Hitch with rotary cutter hookup (LVB25255)

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

iMatch Quick-Hitch with rotary cutter hookup (LVB25976)

One of the greatest customer concerns involves difficulty in attaching tractor implements. John Deere has addressed this issue with the iMatch Quick-Hitch.

The iMatch Quick-Hitch provides easy hookup and a guaranteed fit for all Category 1 implements that are designed to meet the ASAE Category 1 Standard S278.6 for quick-attach hitches.

- All implements require a set of bushings in order for the attachment to fit and work properly with the iMatch Quick-Hitch. One set of bushings comes with the iMatch Quick-Hitch.

NOTE: In the picture above, you see the bushing set. These bushings allow the hooks on the iMatch and the pins on the implement to fit together properly. All other implements (box blades, tillers, rear blades, etc.) will require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier (see dimensions below).

- Upper bushing

- Inside diameter: 0.76-0.77 in.

- Outside diameter: 1.24-1.25 in.

- Lower bushings

- Inside diameter: 0.88 to 0.89 in.

- Outside diameter: 1.43 to 1.44 in.

LP25004 iMatch Bushing Kit shown on iMatch Hitch

LP25004 iMatch Bushing Kit shown on iMatch Hitch

BW15056 Bushing Kit shown

BW15056 Bushing Kit shown

LVU12858 Bushing shown

LVU12858 Bushing shown

LVU15507 Bushing shown

LVU15507 Bushing shown

Overview

iMatch™ Bushing Kits are the fast and simple solution for making 3-point implements compatible with iMatch Quick Hitches.

Benefits

- Fast and simple conversion - to make implements with Category 1 3-point pins compatible with iMatch Quick Hitches

- Easy installation - requiring only a hammer to insert the roll pins

NOTE: All implements (box blades, tillers, rear blades, landscape rakes, etc.) require a set of bushings to enlarge the pin to fit with the iMatch hooks. Bushings of different lengths can be found in the parts system or through a bushing supplier.

Reviews

Location: Johnstown, Pennsylvania

Length of Ownership: 1yearOrLonger

Usage: Daily

I bought my John Deere 1023e in the spring of 2021 for doing yard work and for snow removal. This is a good working little tractor. This is great for small to medium properties. Very easy to operate.

Location: Kingsville, Ohio

Length of Ownership: 1yearOrLonger

Usage: Weekly

I’ve had my 1023 about a year now. Bought it used with 300 hours and put nearly 200 on it in a year with little to no issues. Does everything I need it to do with ease and is very reliable. Green is the way to go!

Location: British columbia

Length of Ownership:

Usage:

Why should I bother. I submitted my review after my tractor with 44 hours overheated due to poor assembly from your point. I recieved an email saying my review was approved etc but surprise surprise it’s not posted. I’m buying kubota from here on out.

Location:

Length of Ownership: 1yearOrLonger

Usage: Weekly

This tractor maybe one of the smallest, but don't let it turn you away. I've hoisted pickup truck cabs and also 8ft pickup truck beds with no issue. Great hard working machine and will do pretty much anything I need around the house.

Location: Clarksville, ohio

Length of Ownership: 1yearOrLonger

Usage: Weekly

Was getting ready to retire and wanted to buy my final tractor, last one lasted 20 years, I bought the John Deere 1023e, and every time I use it something breaks down and cost hundreds to replace. Live on my dream farm but seriously thinking I will have to move. 6 acres of land and due to this tractors expense and down time I can't keep up. Really sad.

Location: South Carolina

Length of Ownership: 3months

Usage: Weekly

I just purchased my 1023e 2 months ago. I have 120 r loader,boxscrape and also bought a set of Deere 42 inch pallet forks. I decided not to purchase the drive over deck.I purchased a Speeco quick hitch at Agri supply. I'm well pleased so far with my purchase. The pallet forks are convenient to have and the quick hitch makes changing implements so easy.I also use a 6ft. Woods scraper blade that is quick hitch compatible.You can accomplish many tasks on your property with this little machine.

Location:

Length of Ownership:

Usage:

This small tractor was one of the best investments I've made for my place out in the country. I till, dig, haul, drag, push, and in the winter I plow a lot of snow at my place. No regrets other than waiting so long to make the purchase.

Location: SD

Length of Ownership: 1yearOrLonger

Usage: Weekly

No support numbers. Hydraulic quick disconnect ...sure disconnect ...just try to connect. Never mind moving levers to lose hydraulic pressure that doesn’t work. Can’t hammer them on even. Nothing quick about that.So...can’t use mower or bucket. No support from dealer or website. So it sits. Sell, sell sell once that’s done good luck.

Location:

Length of Ownership: 3months

Usage: Weekly

This tractor has easily done everything I've asked it to do. I bought it with the 120R FEL and the 54" AutoConnect Deck. I've also used it with the attachments I already had, a 4' box blade and a 4' bush hog. It replaced my 2001 445, which also had a 40 FEL and the above mentioned attachments, but the 1023E despite being of the same hp rating is easily 50% to twice as much tractor without being much larger. My 445 served me very well, but now I wish I had purchased the 1023E much sooner. The turning radius is still excellent, 4X4 with low is super powerful. The drive-over deck and quick park loader are actually just as easy as advertised. My only complaint so far is the cheap plastic keepers for the hood panel. So far I've added the ballast box, quick hitch and the quick-tach pallet forks as well. Dumping the bucket and picking up the forks are as easy as un-clipping tow pins and letting the tractor do the rest.

Videos

© COPYRIGHT 2025 SMITH TRACTOR CO. EQUIPMENT - ALL RIGHTS RESERVED| Privacy Policy | Powered By